New cutting emulsion treatment system at Inasmet

1998/11/01 Elhuyar Zientzia Iturria: Elhuyar aldizkaria

The treatment of waste has always been one of the headaches of the industry and therefore of society. What to do with waste generated in industrial production?

If the question is asked in general, the answers are many, safer than the type of production. If you specify, of course, the answers also to the extent. What to do with the cutting emulsions used in the industry? The system developed in Inasmet can solve what is not being done.

According to Juan Karlos Mujika, "the cutting emulsions – basically oils mixed with water – have not been properly treated. We have developed a process based on electrochemistry that performs cleaning tasks."

The new process and technology have been developed at Inasmet in collaboration with another Basque company, Sader de Bilbao. "As at the laboratory level things went well, in Inasmet we made a pilot plant to check if there were really results. In it we saw that the results were satisfactory, that is, that of these emulsions of cut that contain oil and water were extracted several phases to recover the oil and that the water came out with a fairly good quality, which then remained in a collector or in another treatment plant".

There are no new oils or compounds in this cleaning system. The work is done in the same way as before, but once the pollutant is collected it is a new way. "Used in cutting machines and machining workshops. Once used, this oil contains iron and dust, so you can not use it again as it was, and you have to throw it. This process improves treatment, minimizing environmental impact.

The technology is quite flexible for its implementation in small facilities and then sent to another module to finish the treatment."

And where does the idea come from? "This treatment of organic products is not a new idea, but this application does for these products. We have not done basic research from beginning to end. The treatment of organic products by electrochemistry is something common and known, but in this application we have made an industrial module that is different. We have acquired this experience, applied it to this problem and developed a new process. It can be said that we have done an applied research."

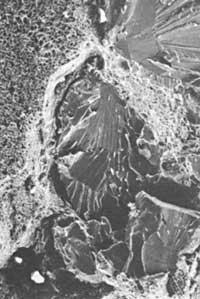

Knowing where the idea comes from, it will not be enough to give a somber explanation of the process, even if there is a more technical explanation elsewhere in the article. "The cutting emulsion is introduced into an electrochemical cell.

Here are several electric charged plates, anodes and cathodes, and first the oleo-water mixture is cut. Then we introduce some products to finish the water process (ferric salts) and the oil remains to recycle it.

In two words we introduce the cutting emulsion and on the one hand we remove the oil to clean it and on the other the water. Because the water extracted from this first cell is of poor quality to the environment, in the second cell another treatment is performed for cleaning by iron salts. The water comes out as if to be sent to the collector, then it is treated in a treatment plant and ends in the sea, it cannot be used to drink. It has disposable quality but not potable."

According to Juan Karlos Mujika, it is evident that the new electrochemical system is, in short, a small treatment plant capable of being located in a factory. What does this mean? macrodepuradoras are in the process of extinction? "I wouldn't say, the water that leaves the system must be sent to a macrodepuradora to finish the treatment, such as domestic water. The water that comes out of our process can have the same quality as the water that comes out of the bathroom of the house. Our technologies and macrodepuradoras are different things, they have little to do, it's something of another level."

Apparently, it looks like luxury technology, as it can be implemented in small areas, with less than 500 employees. Luxury is often associated with famine. "We don't think technology is expensive. The results we already have and depending on them it can be said that it can be competitive alongside existing technologies. We must think that the dumping of objects to the landfill in our country is quite cheap, at least compared to several European countries.

However, before that, it was done as follows: once a treatment was done to the landfill. That had a price. We have looked at these two factors to see whether or not we have made competitive technology. In this sense we have seen that technology is competitive, and within a few years it will be cheaper, because the prices of other technologies tend to grow, I mean landfills."

Being domestic, new, efficient, cheap and affecting a widespread industrial problem, you can think that the new technology developed in Inasmet can be successful. "That is to be seen. The company is responsible for the waste it generates and with this type of technology you will know that its waste is properly treated. Options open there. In Euskal Herria we have relatively small companies that need treatment of this oil.

As before, they themselves will take the waste to specialized companies where the treatment will be carried out. The small workshops will not realize what happens too much, they will only know that the oil they send themselves will be well treated, better than before.

Subsequently, oil treatment plants may be installed in large companies. In the small factories will be used companies specialized in the treatment of oil, in the large plants can be installed. The workshops are small, have little space and are not their work. They will send it to specialized companies and we believe that they will use this new technology."

Despite the use of this or other technology, it is evident that the water is sent to the treatment plants and from there to the sea, restarting the natural cycle, while the oil is recycled. For what? "It will surely be recycled thinking about something else, as it is very difficult to get into the same process, because it has worse characteristics than the new oil. You have to see where you can use this recycled oil, I do not think that it re-enters the process of making the cutting emulsions. Car oils are being recycled and then used for something else, the oil being extracted can have the same use. I don't know what it is intended for, but I would say it enters energy extraction processes mainly."

This technology, which could be successful, will logically require assembly and marketing work. In fact, nowadays there is hardly any product that sells by itself. "Well, you can say that assembly is done in half, working together with engineering companies. We have joined in France, in Toulouse, and we have joined a local engineering company.

This kind of relationships come to us well for the release. In fact, we can say that marketing is done together. To do this kind of work you have to have contact with industries, we have what we have, but engineers who work with us can surely have as much or more than us. This is worked between them."

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia