Hidden factors in product design

1996/07/01 Zabala Lekue, Eduardo Iturria: Elhuyar aldizkaria

In the advancement of the consumer market, the areas that affect the generation of the product have become increasingly relevant.

The product is not only something designed for specific use, it is also something that meets the needs of customers. Therefore, a product that is functionally better than a similar one can be less successful if its marketing approach (sales policy, advertising…) has not been adequate. In order to meet the needs of customers, the product must reach at least these customers. And that's the reason for the importance of marketing.

On the other hand, it must be ensured that the quality level of the product meets the requirements of the market. Otherwise, product acceptance options will determine market demand levels and competencies.

The factors closely related to product quality are reliability, perseverance and maintainability. If quality control has a lot to do with production, reliability techniques also serve to ensure product quality over time. The perseverance of the product indicates the state of the same and finally suggests solutions in case of breakdown. The maintainability, once the product has been made available to customers, facilitates the repair of the same in case of breakdown.

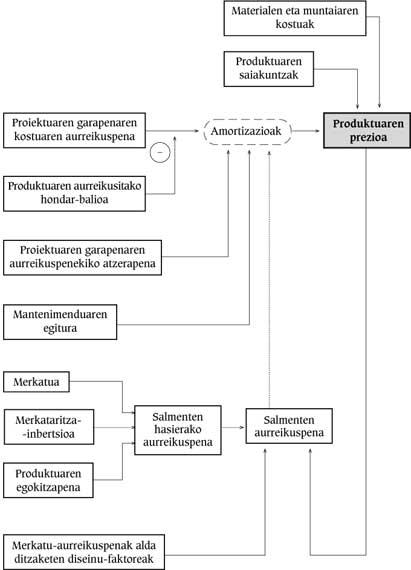

The following outline summarizes the relationships between the main factors involved in the design of a product and throughout its life.

The factors that directly affect the price of the product are the costs of material acquisition, assembly and testing. In addition, the price of the product must be taken into account the cost of some amortizations.

The reliability of the system is the probability that certain functions will be performed in a range based on specific conditions. The best way to achieve reliability is to develop a product with fewer failures. To avoid this, redundant modules are used: if one of them fails, the necessary functions would be fulfilled by those who follow correctly.

The levels of reliability and maintainability defined for a system must be taken into account from the initial phases of the design, that is, it is assumed that one more area is the design.

Running smoothly throughout life is something that happens in very few systems. Therefore, incorrect operation must be within the forecasts.

As a result, due to the risk of system breakdown, an appropriate level of maintenance must be organized. To facilitate this, it must be taken into account from the early stages of the design.

Design factors

When designing a product, the main aspects to consider are the response of the market and the difficulty of the design.

As design difficulty increases linearly, design time and investment increase exponentially. To justify this, market forecasts should be good.

Design organization and management are also the most important factors for good progress. The influence of project designers on the correct development of the project depends on many variables. One of them is the overall performance level of the project. The causes of poor job performance can be very different. The concurrence of these causes exponentially reduces performance. It is very difficult for performance to exceed 80%.

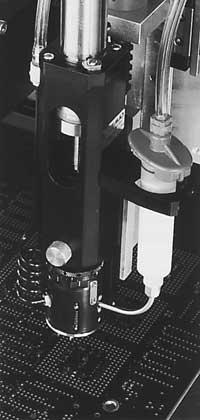

The image above shows the emulator used to help design.

Reliability

System reliability is the result of hardware and software reliability.

When projects are small or medium, generally no calculations or reliability tests are performed. In fact, in these cases there is little money to develop the product and its reliability and need are often unknown.

The greatest risk of delays in the development of reliability occurs when it has not been taken into account since the beginning of the project; the need for reliability is taken into account in the final phases of the project after the approval of the prototypes.

The system's reliability indicator is MTBF ("Mean Time Between Failures"), i.e. the mean time between failures, or what is the same, the relationship between the total running time and the number of failures.

Reliability is generally calculated by MIL-HDBK-217, using the MTBF system. The results obtained are very conservative.

The degree of reliability of a product in some cases coincides with the project specification. In most cases, however, reliability is an indeterminate and mandatory requirement of the product.

The potential risk due to lack of reliability determines the minimum FVTM required by the market.

Reliability testing

Special tests should be prepared to measure the actual reliability of the design.

The probability of failure at the start of life of electronic components is very high so it is known as premature failure. To avoid this, before performing the functional test, the component must undergo a heating process (combustion). This allows to mitigate chemical reactions inside semiconductors, being the operation of a week at high temperature equivalent to that which would occur for a few months at lower temperatures.

The quantification of warming can be approached by the Ahrrenius equation.

Q = chemical reaction speed

A = constant

Ea = activation energy (eV) of the chemical reaction

K = Boltzman constant (8.61.10-5eV/ºK), and

T = absolute reaction temperature (ºK).

For example, if a component that works at 40ºC is subjected to a heating that reaches a temperature of 125 ºC, and assuming a period of 20 weeks of early failure, it would be enough with a half hour of heating.

However, the maximum allowed ambient temperature will be determined by components made of condensers and plastics, in this case 60-90°C.

The margin to overcome the early lack (in the case of combustion) is 48-168 hours, since it depends on the ingredients, the most appropriate value will always be the one that provides the experience.

The great advantage of the reliability error test, in addition to obtaining operational data, is to know the system failures in the long term. These errors appear throughout the reliability test, allowing the design to be corrected.

When the results obtained in the calculation of the FTC or through the reliability test are worse than due, an improvement in the reliability of the system should be developed.

This, in addition to requiring special components or redundant techniques, can entail a rethinking of the entire design, which of course can increase the cost of the design.

Another test to ensure reliability is tremor. Through this session, apart from the types of failures that can be found in heating, other types of failure can appear, mainly bad welds and periodic failures.

Redundant systems

For many teams, the effect of some husuzas is totally unacceptable. To do this, if, taking into account the system components, the required level of reliability cannot be achieved, modules must be designed to support errors using redundant techniques.

Faced with an error, three types of actions can be carried out:

- The system does not lose its features: if a computer system without redundancy has an average availability of 0.99, a redundant can have a utility of 0.999999.

- The system, although it can still work, loses some feature (graceful degradation).

- The system cannot continue to operate, but remains in a safe state.

Software reliability

The prospects for hardware and software reliability are quite different. In empty hardware systems, unreliable behavior is due to component failures rather than design failures. Software shortcomings are direct designer errors and occur in very specific situations.

The most recommended way to achieve the reliability of the software is to code it without vacuum, since in case of applying tolerance techniques the costs would be higher. The reasons for such techniques should be very obvious.

Although these techniques are more complex than those not tolerated, their management is not so, that is, the level to which should be reached will be perfectly defined in the conditions that the products must meet.

Once the coding and debugging of the software is done, the quality level of the software will be measured taking into account the product and market requirements.

Methods for measuring software reliability are not easy to use. One of the biggest barriers is due to the uncertainty between development and data acquisition.

The most widely used method is the one that began to develop in 1973. This method allows viewing the number of vacancies per development phase.

The SAAM method is based on an exponential increase in the number of hours of MTBF testing of the software.

Maintenance

Maintenance includes maintenance and repair. The maintenance program requires significant profitable investments at different times in the life of the system, such as predesign, design and manufacturing.

The factor that significantly influences the repair interval of a broken system is repair service and distance between customers.

The greater the durability of the equipment, the easier it will be to find the destroyed module. If not, to know which component is wrong, specific tools and knowledge will be mandatory.

In general there may be three maintenance policies:

- Post-failure maintenance: no maintenance is performed until failure occurs.

- Planned maintenance: certain repairs and modifications are made at specific intervals depending on the date and age of the component.

- Conditioned maintenance: through multiple system controls you get a deep knowledge of it and you know the component to modify before it fails.

Availability

The variable that indicates in what proportion of the range that the system should operate correctly is AVAILABILITY.

MTTR, indicator of the degree of maintenance of the system, is the mean time of repair (Mean Time To Repair), that is, the relationship between the total time used in the repair of all failures of a period and the number of failures.

Thus, if the system was easily repairable (with a reduced MTTR) the availability would be high, although the reliability (MTBF) was not very good.

The RAM variable (Reliability, Availability, Maintainability, reliability, availability, maintainability) is a utility indicator.

Perseverance

It is convenient that fault detection is clear and visible for easy maintenance. These methods have been significantly improved in electronic systems, especially with microprocessors.

Test systems can be classified into the following levels:

- HAND TEST: The test is done by a person using manual tools. This, though slow, is usually quite reliable.

- SEMI-AUTOMATIC TEST: when the work of the person is between 2% and 50% of the total time. This is of interest for testing similar systems.

- AUTOMATIC TESTING: Equipment is used to reduce maintenance tasks of operators. In general, after thorough analysis and error detection, he communicates it to the operator to study the data and make decisions. Working time does not reach 2% of total trial time.

- INTEGRATED TEST IN THE SYSTEM ITSELF: the components of the test are integrated into the system itself or diagnostic signals can be extracted to be analyzed by another external system.

The most widely used equipment for electronic card testing is functional testing. Such a team can find 95% of the bugs. In addition to its high cost, the programming time of an expert technician is also high due to the complexity of the software it uses.

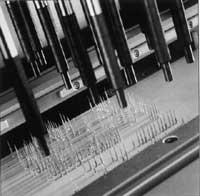

To perform the test in the circuit, the teams perform tests of the parameters of each of the components through the intake bed formed by the test points. Its programming is usually simple and with an average fault detection efficiency of 80%.

The most interesting use of circuit equipment is the combination with those performing the functional test, that is, the removal of part of the load of the functional test equipment, fixing the components with parameters outside certain limits.

The only good way for product approval through prototype testing is to check the worst case performance. That is, the state of testing environment (heat, humidity, vibration, etc.) and the operating level of electronic components must be able to respond to any acceptable situation in the specifications.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia