Plastics and car pollution

1996/09/01 Gondra, Koldo | Hernaiz, E. | Madariaga, L | Vergara, J. Iturria: Elhuyar aldizkaria

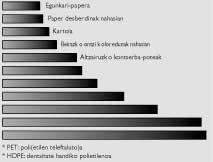

Millions of cars are dismantled each year, according to studies of about 24 million. While recycling your iron materials is no longer a problem (about 75% of the weight), the same cannot be said for all other materials (about 20%). The plastics, rubbers and glasses of the cars are not mostly recycled, that is, for each car that is dismantled generate about 200 kilograms of garbage. It should be mentioned, moreover, that these materials are very light and although their weight is 20%, their volume is much higher.

This problem is becoming more serious, as cars carry more plastic material and more and more cars are becoming. Although much has been researched and written about recycling in recent times, it has not yet been implemented in the industrial field. But what are the reasons why we don't use these materials again in the car? In our opinion, the main reasons are:

- That most plastics used in cars are very cheap, between 100 and 200 pesetas per kilogram.

- Use different materials for the same piece in each home. For example, copelletizers also use polypropylene (PP), reinforced polyester (SMC) and polybutylene-terephthalate (PBT).

- Parts are not generally designed for recycling. That is, it is not specified which plastic is, they are difficult to disassemble and in the same piece different materials are used.

- The requirements that the surface of the parts must meet are very strict, so the recycled material must be clean and of good quality (selective recycling).

- Moreover, the administration has not taken the necessary steps to drive this type of recycling, so there is no adequate infrastructure for it.

And how to solve this problem? Some solutions are:

- Opening of new markets for recycled plastics. As mentioned above, the reuse of material in the automotive sector is very difficult today. However, it seems that the use of materials will be regulated (in new pieces 20% of materials must be recycled). However, management should encourage the use of recycled plastics by extending and encouraging its use to other areas.

- Car manufacturers, unifying parts design criteria and material type, taking into account the difficulty and cost of material recycling in economic analysis, designing removable parts and reducing the number of types of plastics per piece.

- Implementing new recycling standards by management and manufacturers, installing the necessary infrastructure and driving deassembly and recycling centers.

With this one can think that the recycling of plastic materials is practically impossible. But we believe that if we delve into the points mentioned, the problem of pollution can be solved without excessive economic costs. Finally, indicate that the materials that have advantages are:

- Being seven times lighter than steel, the weight of the car decreases by decreasing fuel consumption and therefore CO/CO2 pollution it generates.

- They allow any design, complex geometry parts can be made in one step.

- They have no corrosion problems and therefore should not be painted.

- And dampens the noise and vibrations produced by the engine.

We believe the effort is worth it. So, see if people with decision-making capacity address the issue and provide an appropriate solution.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia