Raw material of civilization

2008/12/01 Lakar Iraizoz, Oihane - Elhuyar Zientzia Iturria: Elhuyar aldizkaria

At the base, cement is a greyish powder that becomes hard solid when coming into contact with water. It also keeps the surrounding elements together. Therefore, it is ideal for its construction as raw material.

However, if we were only able to harden, we could not use the age we use. We use cement for the construction of any type of construction, either for the construction of houses, for the dam of a reservoir or for the construction of a retaining wall of the coast that will be affected continuously by the waves.

It is easy to imagine that we demand concrete certain properties in each case, in addition to being able to harden. For example, for the construction of the house walls it is very important to harden as quickly as possible, to finish the house as quickly as possible. As for the construction of the dam of the reservoir or coastal containment wall, it is more important that its rapid termination ensure that they are able to maintain the pressure they withstand and withstand the corrosion of saltwater from the sea, respectively.

To meet the requirements of these and other uses of cement, around 80 types of cement currently exist in the market, as explained by Juan Luis Querejeta, who works in the cement factory of Añorga, Financial and Mining.

Why so much?

The hardening capacity of cement is given by a certain compound: tricalcium silicate. This is therefore the component that cannot be missing in cement. This component consists of the so-called clinker, which produces in cement kilns. However, they need to carefully monitor the amount of clinker that is emitted to each type of cement, limiting the strength of the cement and the time it will take to harden.

It may seem that it is always convenient to dry the cement as quickly as possible, in short, the faster the development of the resistance of the cements, the faster the completion of the works. However, hardening is often accompanied by other phenomena, and sometimes it is more important to control them than to quickly finish construction. For example, the clinker releases heat while hardening. Heat causes a dilation of the materials. Logically, when this heat disappears, the dilated materials contract.

The expansion and shrinkage of building materials under construction may in some cases pose a high risk. In the case of a house perhaps not, because the amount of cement is not very large. But suppose we have the rush of a reservoir. For the construction of a dam massive amounts of concrete are needed (for example, 110,000 cubic meters of concrete were used to build the dam of the Arriaran reservoir --58 meters high and 206 meters long). Imagine the heat that would occur if they used a cement that releases a great heat, the expansion that would cause and the cracks that would appear when cooling and shrinking in the dam.

To avoid this, in addition to the clinker, other components are added to the cement used in this type of work. They do not affect the hardening capacity, but they do cause this hardness to develop slowly. This means a longer time for the work to be carried out, but at the same time guarantees greater stability in the result.

Anything

Several compounds can be added to the clinker to form a cement with specific properties. But not any compound. It is legally regulated the amount of compounds that can be added to cement, the amount to be added and the use for which each cement is appropriate.

All cements incorporate plaster to curb the rapid hardening inherent to the clinker. In addition to tricalcium silicate, the clinker has tricalcium aluminate, among others. As this compound reacts very quickly with water. Gypsum sulfates, however, slow down this reaction and ultimately allow the cement to be handled before hardening, for example, on the concrete machine.

In addition to remembering before or after, buildings face other problems. Coastal walls, for example, must be permanently exposed to corrosive waters. The use of a cement that does not contain other constituents - apart from the clinkera and the plaster - would progressively dismantle the sea water.

To solve this problem they add slag of blast furnaces like cement. Slag is chemically very stable and allows cement to last much longer.

In addition to slag, they can use different components to achieve one effect or another. Some of these components have natural origin (e.g., puzolan and powdered limestones) and other industrial (fly ash, among others -- solid waste accompanying the combustion gases of thermal power plants -).

Main need quantity

Cement mills need huge amounts of raw materials in order to respond to their daily production. For example, the Añorga factory produces about 1,800 tons of clinker per day, which means about 3,000 tons of raw materials daily. To meet this need it is necessary that the raw materials are very abundant and as close as possible to the factory (to reduce transport costs).

The raw materials for the formation of the clinker must contain silica and calcium to form the aforementioned tricalcium silicate. In principle, as any material containing these two components would serve, each factory looks for those that suit it in the media around it. The source of calcium is usually limestone, abundant everywhere, while silica is acquired through more than one path (the most abundant around): marl, sandstone or sand.

Some of the components that add clinker and plaster have the same effect on cement. Querejeta has explained to us that slags and puzolans of blast furnaces, for example, cause the cement to slowly develop its resistance --pressure level that it can withstand without breaking. Therefore, each cement factory will use one or the other more accessible in its environment.

Beyond waste use

The need for a high quantity of raw materials led factories to start using by-products from different industries, easily obtained. At one point, someone came up with trying these kinds of products, and seeing that the result was satisfactory and that it was a cheaper way to get resources, they decided to keep that path.

What was initially an economic issue has an added value today. Since the 1990s, environmental awareness has been growing, renewing laws and adapting to this goal, etc. One of the most important commitments of society today is the correct management of the large amount of waste we generate. Because waste produced by one industry is raw material for another is a very suitable solution.

Although it began to be manufactured with another objective, the cement industry pioneered this reuse. And now special emphasis is being placed on possible uses of other waste, as in addition to benefiting from advantages for them, they would help preserve the environment.

The environmental impact of cement plants is not slow. Thus, for example, carbon dioxide emissions in ovens are high, heating up to 1,500-2,000°C limestone and silica source in part to form the clinker.

They are concerned and try to minimize the damage they cause. They have maximized the benefit of fuels. However, they know that huge amounts of carbon dioxide must be emitted.

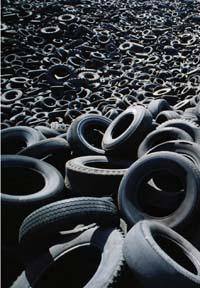

Aware of this, alternatives to fossil fuels are being sought. They use different products, including used oil and wheel tires.

They say that these types of waste benefit from two aspects: on the one hand, they do not have to use oil or coal and on the other, they emit less carbon dioxide. Of course, not because these fuels do not emit carbon dioxide in combustion, but because they would be removed without using them as fuels --to destroy them -, without taking any part of that spill.

On the other hand, cement manufacturing was an important environmental impact with dust particles emitted in factories (ovens, mills, warehouses, etc. ). This damage has always been related to the cement industry: originally they were white-greyish in the cement industry environment. At present, the use of different types of filters for the collection of these particles has greatly reduced the problem they generated.

It cannot be said, therefore, that cement activity is a 'green' activity, but it cannot be denied that, despite the fact that originally measures were taken to improve production, work is being done with the aim of increasingly caring for the environment. Then, what is done with that cement and whether it hurts or not is something else.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia