CD-ROM: giant warehouse (and II)

1991/05/01 Aizpurua Sarasola, Joxerra Iturria: Elhuyar aldizkaria

Physical disk format

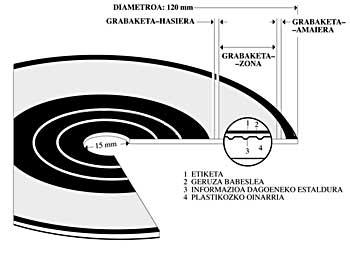

The CD-ROM disc has a diameter of 120 mm, a thickness of 1.2 mm and a central hole of 15 mm in diameter. The information is stored in a small hole spiral on the surface. This plastic surface (polycarbonate) has a luminous metallic coating that is protected by a transparent lacquer.

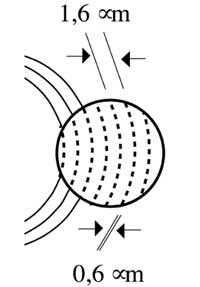

The depth of the holes is 0,12 microns and a width of 0,6 microns. The distance between two consecutive spiral turns is 1.6 microns. Therefore, there are 16,000 finger tracks. In order to better understand the meaning of this figure, it must be borne in mind that there are 96 finger tracks and hundreds of fixed disks on flexible disks. The length of the holes along the tracks is 0.9 microns and the smooth spaces between them are 3.3 microns. Therefore, the length of the spiral of a CD-ROM disc is almost 5 km and there are almost 2 billion holes in it.

To convert the data into holes and smooth surfaces, an operation called master recording is performed, that is, the carrier wave with encoded information passes from a magnetic tape to a modulator (similar to a very fast converter) that controls through a lens the powerful short-wave laser. Finally, the lens focuses on the photosensitive surface of a master glass disc.

The lens moves radially when the master starts spinning. This mixture of movement produces the spiral. When revealing the photosensitive surface, the areas affected by the wave become holes (note that when focusing the laser the walls appear bent in the hole). The emphasis of the master revealed is the same as that of the CD-ROM discs.

From this master's degree more negative are obtained by electroplating or using some photopolymer. These negatives are called arrays and can give definitive form to disks. In general, this last stage is done by injection molding, although other techniques, such as recording or cold stamping, are being tested now. However, the disc material is polycarbonate, so the disc can last despite mistreatment.

Despite the peculiarities of the mechanical aspect in the production of a disc, optics is much more complex.

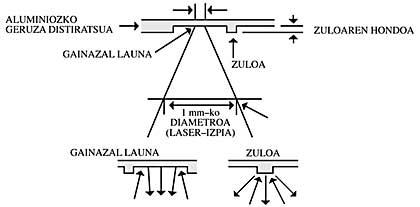

All optical accumulation devices use a laser beam focused by a lens at a small point. The beam consists of a semiconductor of gallium arsenide with oval profile. This oval profile should become a circle of micron diameter. For this it is necessary to collect the ray by a very convergent cone. Convergence is expressed by numerical aperture (ZI). The maximum value of this magnitude is 1 for systems acting in the air. The values of ZIs used by CD-ROM reading units are around 0.5.

To read the information recorded on the CD-ROM disc, the laser focuses on the spiral track with holes and measures the amount of light reflected towards the target. When the light hits one of the holes it spreads at such a large angle that nothing reaches the target. On the contrary, once the light has hit a flat stretch, it is reflected almost entirely. The modulated signal generated from this combination of reflected and scattered light is the one containing the recorded disk information.

The reflected light reaches a photodetector where an electric current proportional to the light intensity is generated. This depends on whether the beam hits the hole. The decoding method called from eight to fourteen turns the information contained in the light signal into a digital data that the computer can use.

One of the characteristics of the optical disc is that the distance between the target and the surface is a few millimeters.

This has two positive effects:

- The strokes between the target and the surface are almost impossible, even if the disc is deformed or the reading unit is badly mounted. For example, the distance between the head and the surface of a Winchester disk is less than 0.5 microns, that is, two thousand times less than that of a CD-ROM drive.

- The laser beam must cross a hard plastic to reach the engraved surface. Therefore, it plays the role of effective sponsor. On the other hand, due to the strong convergence existing, the surface ray beam has a diameter of one millimeter. Therefore, defects and cracks that can be found on the surface do not produce harmful effects.

Rotation speed

The compact disc rotates at variable speed. When the reading head is near the center it rotates faster than when it is next to the edge. Otherwise, the reading speed would be variable. Therefore, and for this not to happen, the speed of the disc when the head is around the center is 535 revolutions per minute and 200 when it is around the edge. This is the reason for the reception of the GIC format mentioned in the previous article. The main advantage of this format is that the density of information remains constant throughout the entire disk, optimizing the accumulation capacity. This format presents a clear disadvantage over the AAC format (Constant Angular Speed): longer access time and data transfer.

As a colophon to this section we will say that those who use especially the AAK format are the magnetic discs.

Data storage capacity

In order to save the bits in a physical environment, they must become something recordable. All codes used for this conversion are called channel codes, as they are prepared to be driven by a communication channel.

Many digital data storage devices, including the CD-ROM, use binary channel codes. Therefore, these binary codes will define the gaps and launas spaces recorded by the laser beam.

The channel code of the CD and CD-ROM systems is called EFM (modulation from eight to fourteen). Converts the user's dautas, error correction, directional, synchronization and other data found in a channel bit stream, into holes and smooth spaces, and sends them to the machine performing the master, where it takes hole shape.

On the CD-ROM read drive deco EFM reverses this operating string and recovers formatted and error correction encoded data.

Since the number of data stored on the track is not constant, the addresses are indicated as on the CD, i.e. in block units of 0-59 minutes, 0-59 seconds and 0-74. The limit of 60 minutes is not normative but of character, although it can be extended up to 74 minutes. As the spiral extends to the outer edge of the center, the last 14 minutes of recording correspond to the external 5 mm of the disc, which present the biggest manufacturing barriers. Currently on the CD these last millimeters are correctly manufactured and this is expected to occur also in the CD-ROM area.

In 60 minutes, a CD-ROM includes 270,000 blocks. Given that each block consists of 2,048 bytes of data plus a total of 2,352 bytes of control, the total capacity is 552,960.000 bytes. If 74 minutes were used, 681,984 bytes would be obtained.

Therefore, this is why there are different accumulation capacities.

Data transfer speed

The CD-ROM reading drive is capable of reading 75 sectors per second. Since there are 2,352 bytes in each sector, the speed reached is 171 kB/s. If you compare this speed with that of fixed disks (625 kB/s), it is clear that it is low. In this field no improvement can be expected in the coming years, since the limitations are both technological and physical.

Access time

The time of residence of the reading mind from the primary sector to the last is greater than a second. And to move from a sector 20 mm away it takes between 300 and 500 milliseconds. Keep in mind that to travel the same distance on the most delicate fixed disks it takes 70 milliseconds.

Error correction

Before completing the master's degree, all data are placed on a computer tape called premaster. This tape has 9 tracks and 1,600 bytes of fingers.

The disc production center reads this tape with the bug correction decoder. It converts user data into another type of data from which it can recover user data, even if the disk has errors. Defects are usually poorly made cavities or irregularities in the protective layer.

If along with the user data the other code data were not recorded on disk, the head of the drive when passing over the wrong data would learn the unknown bitlists.

Codes developed for CDs and CD-ROMs are able to play all akas-tun bits of a signal when one in 10,000 bits is defective and there are 1,000 bit rows, except for one bit per 10,000 billion.

In other words, in 20 million disks there will be no more than one wrong bit.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia