Back to the propellers by plane

1987/10/01 Otaolaurretxi, Jon Iturria: Elhuyar aldizkaria

The aviation sector is really surprising. Some of the technologies that have been used successfully are going to be relegated and after several years of gloom will put them again dressed with new virtues. Something like this is happening to the guiding globe, which is lately becoming fashionable with several globalists.

Something similar has happened to the propeller. It is true that it has not yet completely disappeared since the start, but it had been launched to that path. Now, however, research laboratories have begun to proliferate abruptly and sessions are happening in a thousand ways. They say that from now on we will see them frequently in transport planes. But if all this is founded, what is going on in research laboratories? Is it true that we are at the gates of the helix revolution?

The first planes have flown thanks to the propeller. This was the most suitable system to transform the cylinder engine force into propulsion, the most suitable and the only one at the beginning of this century.

However, in 1939, when a German hunting craft exceeded 700 km/h, they began to highlight the limits of propeller propulsion. In a few minutes the engine was too hot and the cooling system could not solve the problem.

The insufflation speed of the propeller fin is a combination of spin and translation speed, increasing as we approach the end of the fin.

Around the speed of sound (around Mach 1) at a speed of 330 m/s or 1190 km/h and at sea level, the airflow next to the fin suffers complex disturbances due to the compressibility of the air: emergence of shock waves, strong increase of the aerodynamic stela, displacement of the point of application of the representative force of aerodynamic forces and descent of the flow and of the quality of the air from Med. In short, a plane with classic propeller is very bad from 0.65 or 0.7 Males.

During World War II, the Germans began to manufacture the combustion planes in series, but they also built an aerodynamic tunnel to regenerate sonic air flows. This aerodynamic tunnel was projected in Austria, but was finally built in France in Modane-Avrieux. In a hole eight meters in diameter, the air reaches the speed of sound, and forty years later it is now more useful than ever to experiment with fast propellers.

But we came to see how these propellers and fins are. The engineers determined that the fins should be fine and sharp, with the end slightly rounded. In flight the aerodynamics and the helix of the wings are as important as the power at the speed of the plane.

To overcome the speed of sound, they had to abandon the propeller and give the right shapes to the wings of the planes. Therefore, turboreactors appeared with arrow-wings. These have been the hallmarks. They are also widely used in warplanes for speed and power.

These turboreactors had and have a big mistake: consumption. For a kilo of force in an hour, they need a kilo of fuel, which in some planes means five tons per hour. Therefore, for transports of large quantities of materials and long hours of duration, turboreactors spent too much fuel.

Over the years, double-flow and better performance turboreactors appeared, which are finally returning to the use of the helix. However, in some cases the propeller has always been driven by the gas turbine, as in low and medium load transport planes.

But the propeller has encountered many obstacles: vibrations, weight, noise, face repair, limited translation speed, etc. The propeller, however, had a great advantage: its low consumption. But since the fuel was cheap, its impact on aircraft utilization costs was low and not taken into account. But the propeller reappeared when they began developing double-flow turboreactors.

In these turboreactors, part of the turbine acts on the fan that emits cold air. This cold air is rejected by the fan, but at a much lower speed than the hot gas jet emitted by the gas turbine by half the engine.

Applying the physical principle of amount of movement, it is observed that the propulsion performance is better when launching large amounts of air at low speed. The speed should always be higher than the translation speed, of course.

In practice, propulsion performance in dual flow turboreactors is better as the dissolution coefficient increases. The "dissolution coefficient" is the relationship between the amount of air emitted by the fan (cold air) and the amount of air emitted by the gas turbine (hot air). Therefore, high dissolution coefficients are sought.

Keep in mind, however, that the large fan is heavy and the outer circular bracket too. This is also a new aerodynamic obstacle on the plane. Therefore, different solutions have been adopted in different aircraft. The dissolution coefficient of the warplane with double flow turboreactors ranges between 0.25 and 1, and between 1 and 3 in the engines of the training planes and 4 and 6 in the current transport units. In turboprops, the relationship between the cold air flow that crosses the propeller disc and the hot air of the turbomomotor may vary between 40 and 60. The fuel savings it entails, therefore, is very important, since sometimes 40% of its cost of use is spent on fuels, of course.

By increasing the price of oil, engineers began to look at consumption. Improving the aerodynamic shape of the plane have managed to reduce consumption by 10%. The use of higher temperatures and pressures in gas turbines, around 10%, etc. In the coming years, additional savings of 10% are expected thanks to new (lighter) materials.

Engineers have worked on all systems to reduce consumption and one of them has been the latest propeller. One of the most serious problems is shaping fins. Much progress has been made by NASA and Hamilton Standard. These have designed an ultrasonic propeller named propfan (fan = fan).

The first tests were performed in the aerodynamic tunnel and in addition to the aerodynamics the helix noise was analyzed. The good results obtained have led several builders to study the propfan system. General Electric uses a gas turbine and double tip on his UDF (A Ducted Fan) aircraft. Boeing has also announced that in 1992 he will release the "7J7" model similar to 150 places. Douglas and Lockheed houses have shown interest in propfan.

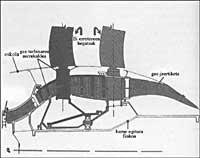

Depending on the different models of propfan, almost all are in favour of double, since together with the simple there is a performance difference of 8 or 10%. However, when deciding whether or not to place a fixed ring around the propeller, not everyone agrees. The profan with outer ring is safer. In addition to having better performance, even with the break of a fin the damage would be minor. On the other hand, the outer ring eliminates the acoustic effects of the ultrasonic helix. These acoustic effects can cause fatigue on walls near the propeller fins. Therefore, free prophylanes (without external rings) can only be placed on the back of the plane. However, rings, anywhere, do not generate these problems. In addition, thanks to the ring the diameter of the propane can be smaller due to its higher performance.

But the outer ring has its disadvantages. It has weight and makes repairs difficult. Also for aerodynamics of the plane. Therefore, the Boeing and Douglas houses have chosen the rings and prophylants placed behind the plane.

Another option is to install a reducer to achieve the most suitable speeds of turbines and propellers. But the reducer is heavy and needs space. It also absorbs power, it must be cooled, etc. Considering all this, the opinions seem to be divided: some are of good performance and others of simplicity.

In the absence of gearboxes, the propane is attached directly to the turbine wheels and thus to the rear of the engine frame. However, if you have reducer, the propellers can be placed in front as in the classic turbopropellers, and the hot gas of the turbine will not affect the foot of the fins.

Thanks to NASA, Allison, Hamilton Standard and Lockheed have joined together to test the simple profan, without outer rings and 3 meters in diameter. A turbomotre of 6,000 horses will affect this profan with reducer. They are already rehearsing on Earth and in the air, flying to the plane, they will start immediately.

For his part, General Electric met in 1985 with SNECMA and have developed the profan of Figure 3. These hope that in 1990 the propofan system will make the planes normally.

Sessions with PROPFAN have also been initiated in Germany and France. But in Europe perhaps the most advanced in this field is the British Rolls-Royce. This house offers different solutions. Specifically:

- For propulsion forces between 4 and 11 tons, double propane without outer ring and with reducer. For propulsion forces between 11 and 18 tons, monorotor, outer ring and reducer.

- For propulsion forces of about 20 tons, double propane, with outer ring and without reducer.

As a result of all these tests, it can be said that the propfan system will succeed at speeds below 0.8 Maches. The second age of the helix is therefore about to begin.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia