Welding the future

At Tknika they take care of new technologies and, among other things, they have brought advanced welding techniques to professional training so that their employees are properly trained.

The bridge between breakthroughs and companies is often made up of people, i.e. employees. The most advanced technology will hardly be deployed in the industry if workers are not trained. At Tknika, they take care of these new technologies in order to integrate them into professional training.

JOSEAN JOUBERT; Tknika: Tknika’s raison d’être is vocational training on the one hand and innovation on the other. So, here we work mostly with teams of teachers. We have two main objectives: to bring the culture of innovation to professional training, and to carry out innovation projects.

NAGORE REMENTERIA; Elhuyar: For example, welding. And that’s what we came for today. Welding is an old technique and has been integrated into professional training for a very long time. There’s been some innovation there, right?

JOSEAN JOUBERT; Tknika: It’s true, welding is a vital industrial process. The requirements are increasing in many ways: in terms of processes, quality or automation, for example. A rapid response to this is needed in order to respond as quickly as possible to the needs of enterprises from vocational training.

NAGORE REMENTERIA; Elhuyar: The heart of vocational training is often found in the workshop. Do you have a shop here?

JOSEAN JOUBERT; Tknika: We have a small workshop, although important ones are in schools. If you think we can go to the workshop and see what we have there.

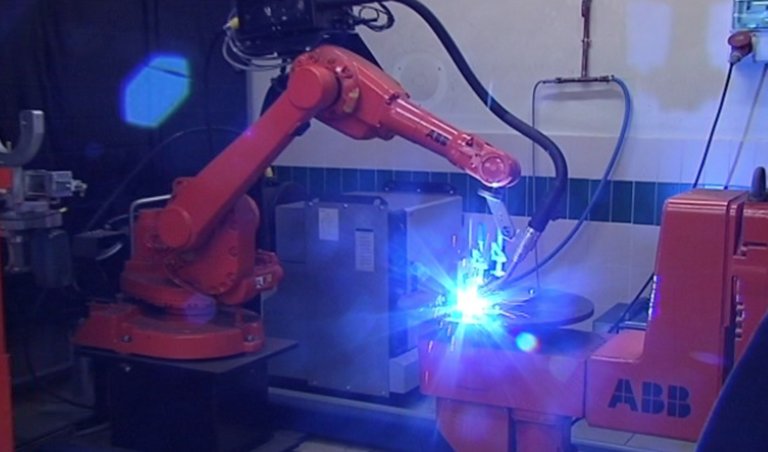

Professional training teachers develop projects to bring technology to their school in Tknika. Such robots are widely used in the industry. They were initially used for large productions, but today they also have them in small and medium-sized companies. In fact, they allow repetitive hard work to be done with quality.

Robots are adapted for many applications, including welding. Students learn the manoeuvre of the robot: programming and moving safely, among others.

MIGUEL ANGEL ERAUSKIN; Don Bosco GLHBI: To do this we will act from the outside; we cannot be in here. Remember that in automatic mode we can not traverse the photoelectric barriers and the movements of the robot will be really fast.

The robot is operating slowly during welding, as welding speeds are one of the parameters to be controlled. But otherwise the robot moves quickly and it is not advisable to be in the area.

NAGORE REMENTERIA; Elhuyar: Is there a way to know without having to destroy a part if a weld or a coating is of quality, if you have problems?

JOSEAN JOUBERT; Tknika: A project in Tknika has been around this. There are many different techniques there.

ANA TOLOSA; Tolosaldea GLHBI: What we have on the table here are surface defects. One method of vision is visual inspection: visual observation. This is what a magnifying glass and a light are used for to see where the defects are. The condition we have here is clear: we need the right light, for this we will use a luxometer.

Students learn different methods to identify mistakes. Perhaps the most visible is the magnetic particles, which cause the appearance of cracks that, although present on the surface, are not visible to the eye.

ANA TOLOSA; Tolosaldea GLHBI: These magnetic particles move under the influence of the electromagnetic field, but stop at the defects. The tool we're going to use is an electromagnetic yoke to affect the piece's field. You don't see any mistakes. I'll throw the electromagnetic particles in the piece... do you see a fine green line?

The ultrasonic method is used to find possible defects within the weld.

ANA TOLOSA; Tolosaldea GLHBI: He's working on this case by picking up the echo. I know this piece is so thick that the ultrasound bounces off when the piece is finished, and the device will tell me how far it bounced off. If he bounces before the thickness of the piece, it is because he has found something, some defect or discontinuity. Measure the following: it's 20 mm. I'll always have to bounce back to 20. Look over there! Something appeared there. A second sign appeared.

This one, this feeler has a lot of crystals. This one has 16 examples. In this way, it emits waves at different angles and opens a fan with a single signal. It doesn’t matter how fast you go because it records the turns of the wheel. So what I get with this is automation: put it on a machine and read everything in the passage.

JOSEAN JOUBERT; Tknika: Another line of projects that we can see here is related to a surface process. Recharges can be made around the surfaces, treatments are also carried out, in this case what we have is a thermal projection or a projection by heat.

NAGORE REMENTERIA; Elhuyar: Does this have anything to do with soldering?

JOSEAN JOUBERT; Tknika: It's not a welding process. It has to do with the fact that there is a sum, but there is no fusion. There's a mechanical sum.

JAVIER ZUZUNEGI; Goierri GLHBI: The purpose is to impart other properties to a material having its properties, e.g. anti-corrosion, anti-friction and/or dielectric properties. We'll get that with a gun like this, an oxygen gun. In order to obtain a flame of oxygen, we have acetyl on one side and oxygen on the other.

The material to be projected is melted in the flame, but the base material is cold and the surface has been scraped so that the material to be covered is better adhered. It is advisable to measure the quality of this projection to ensure that it has adhered well.

JAVIER ZUZUNEGI; Goierri GLHBI: It is this projected material that must be tested if the pantry is well or poorly projected, if the parameters that we have placed are adequate or not. We need to perform two types of tests: one, the tensile test and the other, the metallographic test.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian