The crazy race of chip production

Almost all current electronic devices need, to function, at least one integrated chip or circuit. In order to do more and more complex things that these devices do, chips must be increasingly powerful and their production is becoming more and more complicated, to the extent that in recent years the production of chips is in the hands of very few companies and countries. And in recent years the pandemic, geopolitical conflicts or natural disasters have had a huge influence on the availability and price of chips. To prevent this or the worst from happening again, the world enters a crazy race to extend chip production to more countries.

We are surrounded by electronic devices like TVs, computers or mobile phones, and many others have some electronic component. The initial electronic circuits contained diodes, resistors, capacitors, transistors, etc. soldiers on a printed circuit board, such as the electronic circuits of some devices that perform simple functions. However, the most commonly used nowadays are the so-called chips or integrated circuits (miniaturised electronic circuits made in some semiconductor material, usually silicon) and mainly those of the MOS type, formed by a lot of small transistors type MOSFET. Different types of chips or integrated circuits exist, such as microprocessors (main component and controller of computers), memories, microcontrollers (main components of the computer, i.e. microprocessor and single chip memory), GPUs (graphics processing units), ASICs (integrated circuits for specific applications), SoC (a full computer, including peripherals, on a single chip).

More powerful, more necessary, harder

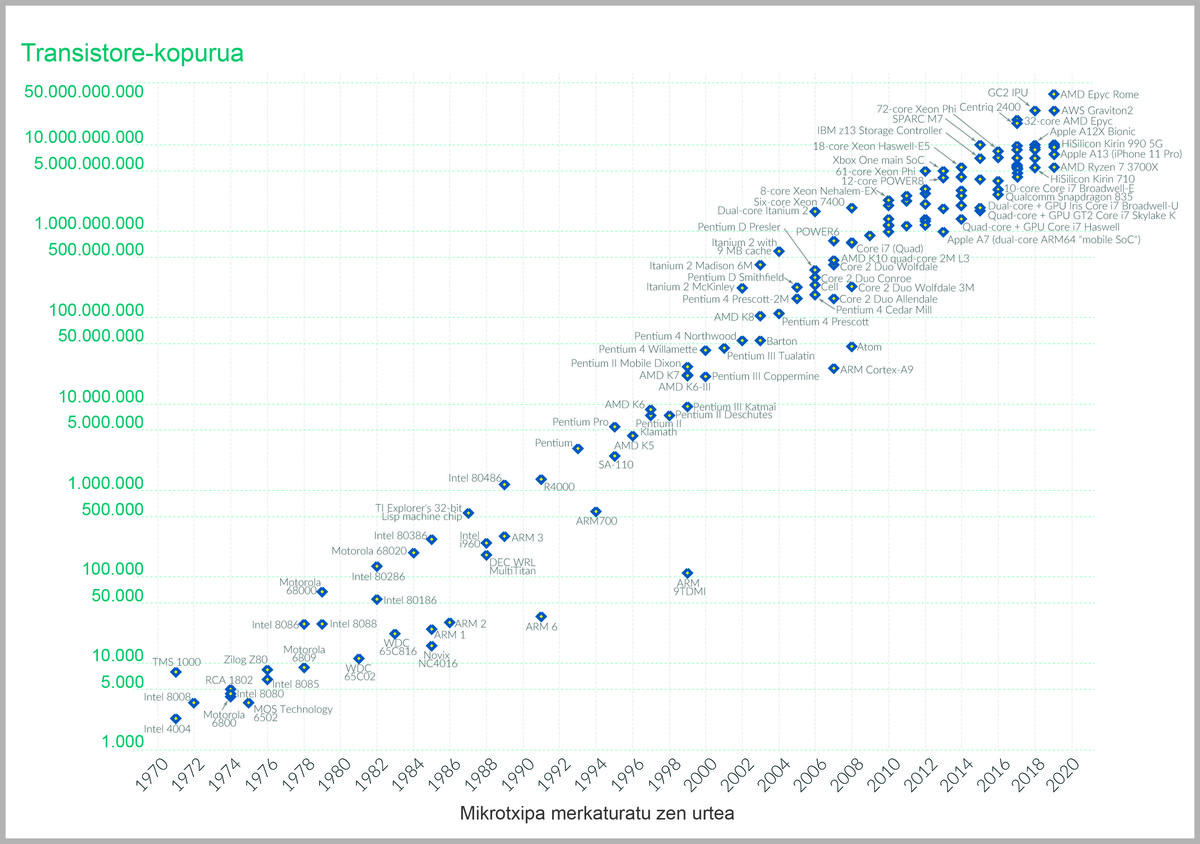

Since the advent of MOS chips, technological advances in their production have allowed MOSFET transistors to become smaller and therefore more transistors to the same size chips, allowing chips to perform more complex and faster tasks. This technological advance has followed Moore's law. Gordon Moore, the founder of Intel, said in 1965 that the number of transistor chips would double every year, and in 1975 he corrected it by saying it would double every two years. And although it is a projection for the future based on the empirical observation of past trends than the law, and although it has been said for some time that as we approach the limit of the molecular size it will be increasingly difficult to comply with, at the moment it is still surprisingly filling almost 50 years later, as we can see in the graph (it is on a logarithmic scale, so real growth is exponential rather than linear).

And the need for more powerful chips has been increasing in the same or to a greater extent: we have all witnessed the amazing evolution that computers and mobile phones have experienced, which without the evolution of chips would not have been possible; the evolution and achievements of recent years of artificial intelligence have also been made possible by the growing UGPUs (originally conceived for video games and the rebirth of adapted 3D images), And because the use of these devices has been steadily growing, the demand for chips has also increased.

However, this constant decrease in the size of transistors greatly hinders chip manufacturing. Today, on a chip, billions of transistors come in, and each of them is about a few nanometers in size. Production machines for these semiconductors must therefore be very precise, avoiding virtually any external influence. The production room must be completely clean (it cannot have the smallest dust particle, it is much larger than a transistor and can prevent a full chip), the minimum vibration (not only the microseisms: the motor of street cars or the steps of the workers can also have a very negative influence), the temperature and humidity must be kept in very small and controlled spaces, and there can be no static electricity. Chips are printed on electronic wafers using techniques such as photolithography.

The producers are scarce and distant, and then you would eat ...

At the same time, the tendency of the entire industry in recent years, driven by globalization, has been the relocation of manufacturing to cheaper countries and the permanence in the west of white collar or office jobs, as has also happened with chip manufacturing. Consequently, companies that today can build semiconductor chips are computable with their fingers, and less so in the last generations (transistors of 8 nanometers or smaller, today they are around 3 or 2): the most important is the TSMC of Taiwan, with more than 90% of these chips; it also makes Samsung Koreans, but mainly memory chips, in the Taiwan plants that make Other chip manufacturers (Nvidia, ARM, Apple...) order the semiconductors in one of the above. There are other semiconductor manufacturers, but they do not reach such small sizes and produce chips for less demanding devices.

That is, most of the best chips are made only in two companies in two Asian countries; in the United States (not at all sufficient to meet their needs) in Europe (the only company that can make the type of photolithography machine necessary to make the most advanced chips, ASML, even if it is in the Netherlands)... But computers or artificial intelligence and therefore the production of chips cannot fail to understand. They repented well when they suffered their consequences! When COVID-19 pandemic closures caused restrictions on the manufacture and transport of chips, stoppages – and even closures – occurred in the automotive industry around the world. And there is always a risk of similar situations being repeated for other reasons, whether it be natural disasters (the earthquake in Taiwan in April, in addition to the soil, or by many governments and companies in the world) or geopolitical conflicts.

Now, the race for productive capacity.

In recent times, with accumulated experience, many countries appear to be in full dispute over a secured supply of chips through the construction of semiconductor factories or other measures. The United States, for example, banned selling chips to China in 2022 to companies like Intel, Nvidia, and pressured other countries to do the same, like South Korea, to combat the shortage of chips caused by the pandemic and, by the way, to weaken the competition of the industry of a country that is economically opposed. As early as 2018, it had banned government institutions from using devices manufactured in China (Huawei, ZTE...).

But above all EE.UU. And many other countries are driving the production of chips on their lands, which is not easy because of the complexity of chips: the cost of building a new semiconductor production plant is several billion dollars (numbers from 1 to 20 are mentioned), and it is not something that is built and achieved quickly; it is a process of years.

However, some Governments have put in place new laws, ambitious plans and major investments over the past two or three years. In 2022, EE.UU. approved the CHIPS and Science Act and the European Chips Act with the aim of boosting the production of chips and major currency items. And in 2023 and 2024, the TSMC has launched the construction of production plants in Germany, Japan or the United States, and in the latter, Samsung, with offers and subsidies from local authorities. South Korea has launched a $470 billion plan for the construction of new semiconductor factories. India has launched a plan to have chip production plants in 5 years. Sam Altman, leader of the company OpenAI, hopes to get 7 trillion (yes, trillion) to build many chips from private sources. A very ambitious but unrealistic claim ...

Paradoxically, China has at the moment achieved the best results in producing advanced chips. Since 2015, the Made in China 2025 law and its investments have been in place, and the veto has left him no choice. And China has an economic muscle, a population and an attitude to face such difficult challenges. Thus, in a very short time, the semi-public owned SMIC company acquired last year the ability to make 7 nanometer chips and continues to improve.

We will certainly read over the coming months and years a lot of news about this crazy race that is trying to turn around the incomprehensible concentration of chip manufacturing capacity.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian