TGV. New high-speed train

Between the Atlantic and Mediterranean TGV, apart from the colour, there is no apparent difference. One of them is blue and another is orange, and from the outside they are the same: shape, silk, etc. However, if you analyze it very carefully, there are differences. It has something altered the body of the locomotive and between the first and last motor cars, the Atlantic TGV (which now goes to Bordeaux) has another ten cars, while the Mediterranean has eight.

There are also differences in the speed of both. The normal TGV is 270 km/h and the Atlantic TGV is 300 km/h. However, to get 30 km/h more with the passengers, keeping the same dress outside, has had to change much the interior machinery. The engines are new (lighter and double power), the brake capacity is 70% higher (and also have anti-lock mechanism), pneumatic suspension, lighter cars, etc.

Structure of the TGV

However, the basic structure of TGV has been maintained, since the practice has shown that it is very suitable for its operation. The complete train consists of two motor cars (the first and the last), among which have formed a homogeneous set of ten articulated cars, with a bogie under the intersection of two. There is, therefore, as in the classic trains, a locomotive and then independent cars, each with two bogies.

The structure of TGV has its advantages. Having less bogies and lacking space between cars, the air generates less turbulence and is aerodynamically much better. Bogies of three meters with motor suspended. The motor transmits the turning speed to the wheel by means of a reducer and homokinetic junction (as in cars).

Getting faster and faster

As for the speed of the train, the change of the normal speed from 270 to 300 km/h has generated many problems, more than 200 to 260 km/h. The usual speed of 200 km/h was reached in 1967 by the “Capitole” train which was travelling in France from Paris to Tolosa. In 1981 the normal TGV speed was 260 km/h. To achieve this, however, the materials and structure of the train were completely different. The operating and intermediate wagons formed a much lighter articulated assembly.

Speed problems

Accelerating speed seems quite easy to the naked eye. It seems enough to put more power for traction, but things are not so simple. If we tried to set a speed of 300 km/h to a normal train, it would be downloaded as before the track and the bogies would not be prepared for it. In addition, this speed would increase the braking problem.

The increase of the speed implies, therefore, the development of different parameters opposing each other. It must be lighter to overcome on the one hand the inertia of the mass to accelerate and brake, and on the other hand, have greater power. However, to transmit more power it is necessary to have more weight.

The forces at stake in the train rise depending on the square of the speed and depending on the cube of the power speed or the square. For example, the speed of passage from 100 to 200 km/h would require four times the resistance and eight times the power. There has also been an increase in the speed of 11% (from 270 to 300 km/h), an aerodynamic resistance of 23% and a power of 36%. In practice it has had to review everything on the train: suspension, stability, passenger comfort, braking, signaling, etc.

New Railway Station

The lanes, however, have not meant great headaches, since in the design of the tracks for TGV were taken into account speeds higher than 300 km/h. That is why they have experienced the world record.

But do not forget what happened in 1955 in a straight section of Landeta. The experimental trains CC and BB reached a speed of 331 km/h, but the railroad was full of waves and deteriorated, so everything was renewable. At these speeds the side strokes of the wheels of the bogies are enormous (they grow according to the square of the speed).

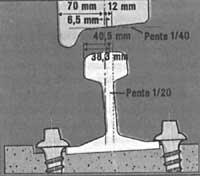

The railway for TGV, therefore, is much heavier, stable and more accurate than the normal railway. The rails are heavier, 60 kg/m (normal weigh 45 or 50 kilos) per meter. They are better settled on the ground and at the same time they have carefully controlled parallelism and alignment. Precise optical instruments have been used so that in a kilometer length there are differences of few millimeters.

Each kilometer of track for TGV has an average of 4,000 tons of ballasts, 1,600 nests (392 tons of weight) and 120 tons of lanes.

Motors and power of the locomotive

However, to circulate at those high speeds, in addition to a good railroad, high power machines are needed. Although the size of the locomotive can only be assumed, the largest space is not occupied by motors, but transformers, fans, current rectifiers and current modulators. The engines are very low between the wheels of the bogies. Therefore, they have very little space. We must not forget that in addition to the engines, the gearbox must carry its own gears and the transmission boxes. The Mediterranean TGV engines are direct current, with 550 kW or 750 Z.P. Each one. At present. The Atlantic TGV has autosynchronous engines of 1100 kW or 1500 hp each. This means twice as much power, despite being heavier (1430 kg).

To briefly indicate the operation of autosynchronous motors, the compass can be rotated by moving the magnet around it. The magnet can be replaced by three fixed coils around the needle. In three coils you can pass alternating current, creating a rotating magnetic field and spinning the compass. In practice, the compass is replaced by a rotor with coils. In this way we achieve a synchronous motor of excellent performance, but has its obstacles. On the one hand, it does not come out alone and on the other, it rotates at the speed that marks the frequency of the current. Obviously, it is not split because the magnetic field created in the stator is put to a blow at 3000 revolutions per minute (50 Hz current) and is affected by the inertia of the rotor.

The magnetic field must start rotating slowly so that the rotor starts slowly. Therefore, the frequency of the current must pass progressively from zero to normal frequency. This is achieved today thanks to the semiconductors.

Thanks to the circuits made with semiconductors, the moment of the torque is maximum when starting (as in the motors of continuous current), obtaining high yields and obtaining a great power compared to the own weight.

Being the smallest engine can be placed better in the bogie. Bogie's axle space is small and between wheels or lanes (1,435 m) and the conventional DC motor would not be possible.

Each bogie has two axes and its engine, 1,300 kW or 1,750 horses. The Atlantic TGV has two engine bogies in front and another two behind, so with eight axes can give a power of 14,000 horses at the start and 12,000 ordinary speeds.

In short and experimentally each engine can provide 1,900 horsepower (a total of 15,200), which has allowed to break the German mark of 406.9 km/h.

Comfort of the train

With all these powers of the engines, the train must be maintained at a speed of 300 km/h without vibrations and with total stability. In this they have much to see the inclination towards the interior of the rails and the conical profile of the wheels. This form makes the wagons always have a tendency to go in the middle of the lanes.

When the train is in progress, the left-right vibrations are always frequent and the basil bumps in zigzag increase depending on the speed square, damaging the stability of the entire train. The comfort of travellers, of course, is not beneficial either.

Bogies Bogies

In the Mediterranean TGV it was shown that the wheelbase in the bogies was 3 meters. Keeping this distance, the connections between bogies and axes, as well as between bogies and wagons were reviewed. It is advisable to have a light bogie. On the one hand, the bogie is the only mass that is not suspended and, on the other hand, the faster it is, the fewer blows are given to the railroad.

The bogie motor does not directly support the engines. The motors are attached to the frame of the machine and the transmission to the wheels is made thanks to a homokinetic link. However, between the wheels and the bogie there are complex elastic joints to cushion progressive, vertical and basil (zigzag) efforts. To measure and control all these parameters, the computer has also been used.

The carrier or intermediate bogies are the same way, size and stability as the tractor bogies. Each carrier bogie holds the ends of two consecutive cars. That is why it is very important that the bogie vibrations are not transmitted to the wagons. The union between both cars is made by a large ring that is made by a new pneumatic suspension of the bogie.

Although it seems surprising, most pneumatic shock absorbers are placed horizontally, as the oscillations are produced by bending. The balance between the tyre that transmits and cushions the oscillations from one wagon to another horizontally to the whole articulated train, at a speed of 300 km/h, provides the passengers with a unique comfort and comfort.

Braking of the train

Although the train has tried to do it as quickly as possible, when it is loaded it has a total weight of 490 tons. When all this mass circulates at a speed of 300 km/h, in case of emergency it must stop as quickly as possible, less than three and a half kilometers. For this, as usual, it is not enough to put a brake on each wheel.

The motor bogies have on one side of a brake shoe in wheel and on the other the engines stop acting as alternator, since they stop being motors to become generators, eliminating the electric current generated in the form of heat through a reostat. The synchronous motor can also be alternator. For this purpose, first the current to which it is supplied is eliminated and then the excitation current is sent.

This is not enough to properly brake a train of 490 tons. In addition, each axle of the wheels has 4 brake discs (88 discs in total). In addition, these high-power discs should not be ventilated when braking.

Railroad Railway Station

To complete this machine, it has been necessary for semiconductors and electronics to reach the current development levels. It would take a long time to describe the electronic circuits of the Atlantic TGV locomotive, but we will say that the main objective is to capture the electric current from the catenary of the line (alternate of 25,000 volts or straight of 1,500 volts) by means of a pantograph and convert it into a current suitable for autosynchronous motors.

Computer science also plays an important role in the safety of the train. The machine driver is informed by numerous microprocessors after automatic signaling and control operations. Many of the safety elements of the train are analyzed by microprocessors: brakes, stability of bogies, operation of the elements of traction and transmission, temperature of the axes, operation of the signals, etc. Let's say that the Atlantic TGV is the best preserved in safety compared to other French trains.

It is also a cheap train from the point of view of consumption. This train needs 1.5 liters of gasoline per passenger and every one hundred kilometers, which moves three hours from Paris to Bordeaux. From the point of view of consumption will undoubtedly cost to break the mark marked by the TGV Atlantic.

Wagons of cars

If we look at the wagons, everything has improved compared to the Mediterranean train. Improvements in interior decoration have been made and new types of rooms have been installed. The train has a first class room, rooms for families and groups of travelers, rooms for children, nursery, telephone booths, etc.

The exterior color of the train has also changed, as it is blue and metallic grey. Painting with metallic pigments a train of 238 meters is not a joke, but it can not be denied that it has gained in aesthetics.

The cars can take a total of 522 passengers and take them at a speed of 300 km/h, taking care of the important silence, speed and safety.

Given the characteristics of this train, the buyers have approached shortly. They are already customers of SNCF in France and RENFE in Spain, and from now on, of course, will have other buyers.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian