The laboratory has reduced the energy consumption of robot joints by 40%

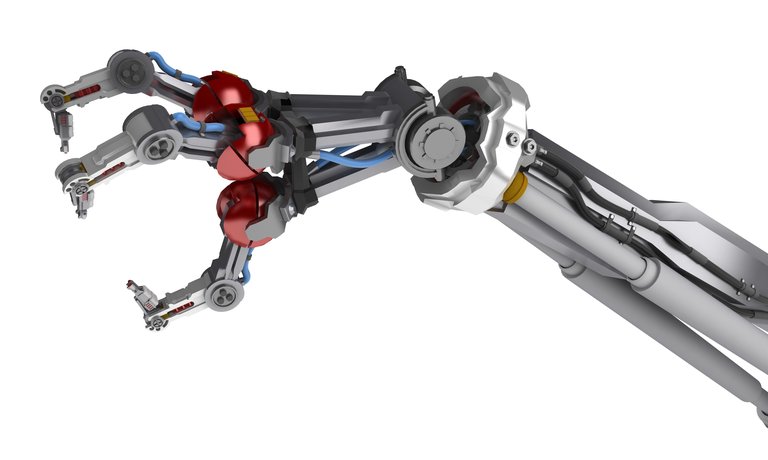

The use of robots in industrial processes is very intense due to their ability to perform repetitive tasks quickly, accurately and reliably. Currently, the joint motors of these robots are driven by digital controllers. Developing and programming for all of them to work efficiently is a great challenge. Unai Ugalde Olea, professor at the Department of Electronic Technology of the UPV-EHU, has analyzed the path to greater energy efficiency of these robots, detecting in some cases a 40% reduction in energy consumption at the laboratory level.

Digital controllers only give orders at certain times (in discrete time), “you can say that they send orders by sampling or by beats: now a small pause and then another small pause… and so,” explains Ugalde. In fact, in this work the researcher of the UPV/EHU has made a new proposal for this sample art without orders.

In general, in the industry, until a new order is reached, the last one remains. That is, until the new control order arrives the previous one is attended. “In this study we have seen that this trend can change. Based not only on the last order but also on the penultimate, we have used a polynomial function of both values to reconstruct the process,” said Ugalde. “That was precisely the innovation of research,” he added.

Ugalde is based on the methodology called “Fraction Order Reconstruction”, which has proven its special interest in flexible joints such as elbows and robots wrists. Laboratory tests have shown that “the energy needed to move the engine is considerably reduced, in some cases idealized up to 40%, without losing the accuracy of the promised route,” said Ugalde. The next step would be to check if that savings can also be achieved at an industrial level. The results of the research have been published in the journal Control Engineering Practice.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian