Solar Car Race: Latest Technology Test

Curious career

VIKING XX, a curious artifact

Few would give a car name to the vehicle presented by Western Whashington University. In addition to the driver has space for another passenger and has a giant solar panel: 16 m.It is endowed with monocrystalline silicon cells. Knowing the cost of these cells and the surface of the panel, you can see that this vehicle is not one of the cheapest.

The race ended on November 16, 1990 in Adelaide, south of Australia, after touring for 6 days 3,007 km from the north coast of Australia to the south coast. This is the second time this race is held. It was first performed in 1987. Then there were 22 participants. In this second they have been 36, of which 10 reached the goal.

The race rules are simple: vehicles must start at 8 a.m. and stop at 5 p.m., where they are. Vehicle dimensions are also regulated: 4 meters in length, 2 meters in width and 1.60 meters in maximum height. The maximum surface of the solar panel is 8 m 2. However, if in addition to the driver there is another passenger, the surface of the panels has no limits.

In addition, the vehicles have electric batteries. Loading of the vehicle panels with solar energy before 8 in the morning and after 5 in the afternoon. The capacity of the following batteries is also limited: up to 5 kW/h.

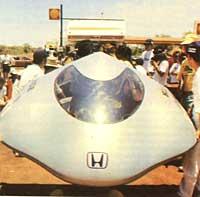

Dream, the expensive toy of the Japanese house Honda

panel consists of thousands of monocrystalline silicon cells, whose yield of 19% did not exceed 14%. Dream was the tenth goal of Adelaide.

As in the races, or more specifically in the Olympic rowing with helmsman, the weight of the helmsman or the weight of the jockey in horse racing is very important, in the race of solar cars the weight of the driver can be a determining factor. To avoid this, a standard weight is established: 85 kg. Vehicles with a lower weight driver are loaded until the driver plus the load equals that weight.

How are solar cars?

Solar vehicles are low power: From 1 to 1.5 kW. Within this power limit they must be very light to get the maximum performance. They weigh between 150 and 200 kg and have an aerodynamic shape to reduce friction with the air, defined in the aerodynamic tunnel. In addition, to reduce friction with the ground, they use tires such as bicycles and are usually three-wheeled. With these features and the battery charged, one of these vehicles reached a speed of 130 km/h. It's not easy!

Solar energy is transformed into electricity into solar panels. Performance: approx. 10% in conventional panels and almost 20% in more recent experimental panels. That is, if the sun dissipates 1,000 W per square meter, and this is something common in Australia in November, before summer, the best solar panel will hardly reach 200 W. In addition, when the temperature exceeds 25æC, which is normal in the Australian desert, the performance of the components used in the construction of the panels decreases.

SOUTHERN CROSS, poor Japanese

Southern Cross panel cells were not monocrystalline silicon, but amorphous silicon, that is, have a much lower performance, since it does not exceed 12%. The panel provided a maximum power of 600 W, reducing car speed: 70 km/h maximum. But the main advantage of this panel is its cost/power ratio: 700 sts. (40 pounds) per watt, while the cost of monocrystalline silicon panels is 90,000 pesetas per watt (5,000 pounds).

The World Solar Challenge was held for the first time in 1987 and the truth is that subsequent panel performance has barely been achieved. Do not increase performance, but reduce the price of panels. The data is: The 1987 winner, the well-known manufacturer General Motors, invested in his vehicle about 400 million pesetas (21 million pounds). He used a panel of gallium and arsenic cells, obtaining a yield of 18%. The winner of 1990, the Biel School of Engineers in Switzerland, only exceeded 63 million pesetas (3.5 million pounds) to build his own vehicle, with a panel apparently of 20% performance.

To do this, he built the houses of Telefunk and used new cells, a prototype, which are not yet manufactured in series. These new cells have been designed by Martin Green, professor at the University of New South Wales in Sydney. They are squares cut by a simple silicon crystal. The surface of these boxes is flat. Through the laser, summits and valleys are recorded on the surface, that is, the cellular surface is rugged. Consequently, the surface of the box increases and with it the performance.

Swiss with car Spirit of Biel champions

These cells begin to be manufactured later this year in a new factory that British Petrolium Solar is building in Spain. Therefore, its price will be much cheaper than the current prototype. In addition, being these silicon cells are not toxic, since the biggest problem of gallium and arsenic cells was toxicity.

Not only the panel components, but also the shape and layout of the panel itself: semi-cylindrical panels, launas panels, orientation panels,... all types of panels designed to better absorb solar energy were seen in the race.

Solar car racing has become a real tester for the world's most powerful industrial groups. Solar energy, in addition to being a legitimate claim of environmentalists, has become a business. As proof of this, some of the participants are: General Motors, the world's largest car manufacturer, sponsored teams from three U.S. universities. Three large Japanese companies were also present: Honda, Toyota and Mazda. Nor were the big oil companies lacking: BP, Mobil and Amoco.

Expensive and polluting

General Motors spokesman said: These will not be the cars of the future, but these young people who are here will be the car designers of tomorrow.

Does the solar car have a future?

Despite the success of the solar car race in Australia and the presence of the most powerful industrial groups in the world, it is not necessary to think that the solar car will be the bargain of tomorrow. The director of the group, Honda, noted that the future of solar cars is quite dark, as the current performance of solar cells is at the gates of its theoretical limit. In other words, the performance of 20% of today's best photoelectric cells will hardly increase.

Solar Engine

arrow in the image shows a parable behind the pilot's station. The parable concentrates the heat of the sun and applies it to a stirling cycle engine. The

Stirling cycle is known in thermodynamics, consists of the movement of a gas between two heat sources separated by a constant volume adiabatic heat exchanger. In the

Aisole engine two pistons and two connecting rods convert the expansion of the gas into a closed circuit into mechanical energy. Solar energy is the cause of gas expansion. The

explosion engine (internal combustion engine) must have two external elements: fuel (e.g. gasoline) and fuel (air). The Stirling engine, for its part, only needs a source of heat from the outside, whether gasoline, alcohol, wood or as in this case the sun.

However, the power of this solar motor is very small: 80W, while the Aisole solar panel has a power of 900 W. However, this is the first time a solar motor is made and a new research path has been broken.

However, the electric car has a solution, powered by electric batteries. The electric car of the future will be equipped with solar cells to recharge batteries when parked in the sun or under the sun.

The batteries used in current cars are too heavy and low performance. In addition, when they age they cannot be thrown everywhere, since they contain heavy metals, that is, they are harmful to the environment. However, the battery that has just been developed in Japan can change status. The new battery is in the form of a capacitor, which stores electricity between two metal plates separated by an insulating layer as static electrical charge. This is the revolutionary innovation of this battery, as conventional batteries store energy chemically.

The car manufacturer Isazu and the firm Fuji Electrochemical are the authors of this new battery, which has announced that it can accumulate between 30 and 50 electric charges more than the best capacitor available on the market today. On the other hand, compared to the conventional lead and acid battery of cars, it has a capacity 20 times greater than equal weight. In addition, the internal resistance of this battery capacitor is very low, it takes only 30 seconds to charge and is also charged with a voltage lower than normal. This battery will be cheaper than the current one and clean, since it does not contain heavy metals. Active coal and sulfuric acid. Designers believe it can be on sale within two years. See.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian