Microsensors analyzing gases

When using natural gas-fueled fire to heat water, it is difficult to think about how micro and nanotechnologies can help improve this experience. These technologies can still be used, for example, to measure the quality of natural gas at the moment and also in the consumer’s own home. This small device is capable of doing this. It performs the function of large and expensive laboratory machines by supporting the characteristics of natural gas. The result is accurate and immediate.

ENRIQUE CASTAÑO; Project Ard., CICmicrogune is: The gas has many origins in Algeria, the North Sea, Russia... and they all have a different heat capacity. From the point of view of the gas that comes to the house, it is not too important but in industrial processes it is essential to know this data.

The ultimate goal of the project is to develop a smart gas meter with the microdevice inside.

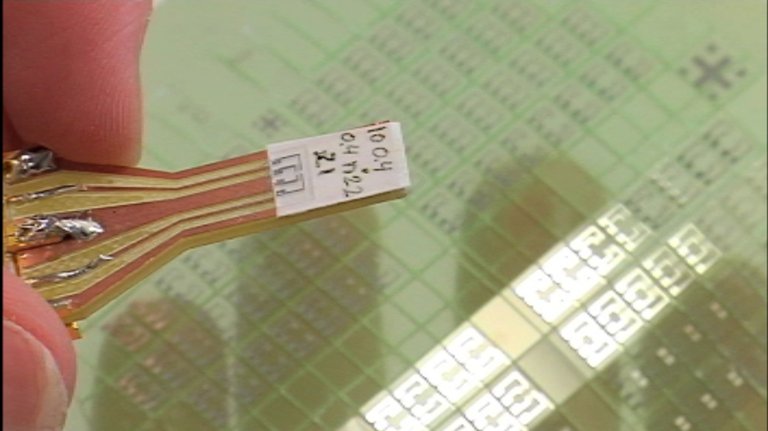

IRENE CASTRO; carbonizer, CICmicrogune: In short, we have a piezoelectric substrate in this case quartz, on which we place metal electrodes, these electrodes generate mechanical excitation on the substrate, a wave is generated and the wave propagates on the surface, and will have a different speed depending on the environment

Consider that the sensor is in contact with the fluid in the fish tank. Well, the wave is generated by the sensor itself, as if it were a hammer, and the device itself measures how it propagates. The fluid on it will condition the velocity and amplitude of the waves across the surface of the microsensor. The thicker or more viscous the contour, the more difficult the wave will propagate.

ENRIQUE CASTAÑO; Project Ard., CICmicrogune is: Then, by measuring the amplitude of the wave that reaches point A to point B or knowing the speed at which it propagates, we will know the viscosity of this gas and therefore its heat capacity.

This is done in the laboratory. They characterize different samples of natural gas. The gas flows through these tubes and enters the chamber where the sensor is located. The reading of the wave reaching point B will give us the characteristics of the gas.

ANGEL GUTIERREZ; R&D department, edp-naturgas:We are in the EDP-Naturgas energy control room, from here we monitor our entire gas distribution network

EDP-Naturgas leads the team behind the project. The parameters they now receive here are the pressure and temperature of the distribution network. In the future, they will measure the quality of the gas, i.e. its heat capacity, and in the customer’s home or factory...

ÁNGEL GUTIÉRREZ; R&D department, edp-naturgas: If we knew the heat capacity online and in situ, we would also be able to monitor the combustion parameters, solve the combustion defects and in some way be more efficient, save energy and use gas in a more rational way.

The idea is also to use this data to calculate what needs to be paid, along with the cubes of meters.

There are sick buildings. Those who live or work there cause discomfort and evils because the local air is of poor quality. Up to now, the comfort of a room was monitored by looking at the temperature, humidity or, at most, the amount of CO2, and the air was conditioned accordingly. However, with the appearance of phenomena such as the sick building syndrome, it has been observed that it is insufficient and that the air quality is also measured by other components.

ENRIQUE CASTAÑO; Project Ard., CICmicrogune is: For example, the smell of plastic that we have ever noticed, the smell of news when entering a car, these odours are caused by volatile organic compounds: benzene, formaldehyde, etc. There is no microsensor on the market capable of measuring these gases. At CICmicrogun we are working to make air control in this area also intelligent.

Surface waves are not used to detect these gases. In this case nanowires, nanometric wires, which are much thinner than a hair, are used. The electrical resistance of these nanoharis, that is, their ability to conduct electricity, varies depending on the gas that surrounds them and the concentration of this gas.

ENRIQUE CASTAÑO; Project Ard., CICmicrogune is: This is advantageous because by measuring the conductivity of the wires you can know if there is gas but at the same time it is also a problem because they respond to any gas and I am not interested in any gas, I want to know if they are benzene or formaldehyde. So “tuning” these nanoharis, we have to cultivate them so that they can detect the gas we want.

The part of the sensors that reacts with the gas, the sensitive part, is arranged as a chessboard. Each square, this area of the nanoha, is doped with small amounts of impurities, that is, elements that modify its electrical characteristics are added. They are usually noble metals, such as palladium or platinum, and are thus prepared to react with the desired gas and not with another.

The electrical resistance of each area of the sensor is calibrated in the laboratory. By mixing the volatile compounds in certain amounts and introducing the device into this cocktail, it will only ignite the alarm, so to speak, at concentrations that are dangerous to health. Naturgas intends to use this detection capability of the device as a safety factor.

JUAN RAMÓN ARRAIBI; distribution zuz., edb-naturgas: For example, if there is too much carbon monoxide in a plant we know online that there is a risk there. Until now, customers have called us in such cases, if there is a problem and that, thanks to this project, we can find out online, in the moment, and that would be very important in terms of certainty.

Or if there's a gas leak, they'd get a warning in a control room like this. Not just natural gas, they would integrate sensors into air conditioning systems to test the ability to detect dangerous concentrations of volatile compounds, so they can start cleaning air above a certain level.

ASSISTED BY JURGI GLEZ. DE TXABARRI; researcher CICmicrogune: This is the prototype we have at the moment, our idea is to put air conditioning as an additional element to know if the air we have in the rooms is of good quality or not. Here we have some filters to dehumidify the air and raise the temperature, here the sensor, and finally a pump to control the air flow.

The prototype is almost ready to be used, it is expected to soon make its way from the laboratory into a conventional device.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian