Virtually welding them

Traditional professions are internalized through the use of new forms of learning in the Superior School of Professional Training.

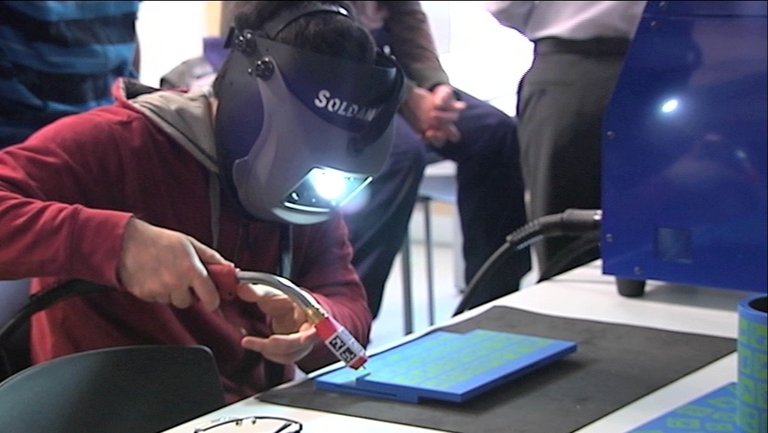

It's not a video game. They're schools to learn how to weld. Turning to the saying that you learn by doing things, you don’t use fire or metal to make seams. Sign coated parts can be welded as if they were actually working with the help of these and a powerful graphic technology. The system has been developed by an Andalusian

company. ALEJANDRO VILLARAN, seabery: These are augmented reality markers, some kind of barcodes that tell our system what each element is, that this is a mig-mag torch, and where it is located in space. As you can see, the pieces are also full of markers, exactly the same.

This is also a reality, but exacerbated. Compared to virtual reality, in augmented reality there is no loss of reference to the environment, the two are confused. The student can take the piece in his hand and see how the thread has come

out. Mikel is a welding teacher. Until now, there was no other way to learn and teach how to weld than the traditional way, a method that has not changed in years.

MIKEL AZKARATE; professor of metal construction: Imagine that 25 young people come, jump into the workshop after giving the theory and each one enters a cabin. I go to each one and spend 5 or 10 minutes. Maybe I've spent every 3 hours in a class with every student, and he's throwing and throwing the pieces, welding them. He sees it wrong but doesn’t know why. So the advantage of this system is that it directs the student every moment and guides how to do it.

MIKEL AZKARATE; professor of metal construction: Xabi, you see different lines here, don't you? The line at the end of the gun is the distance to the piece, the length of the arc. The round will mark both angles, the welding angle and the displacement angle and that other line behind us is the speed. You have to try to have them all in green, if you have them in green it means that the welding parameters, which are related to the movement, are well carried.

This self-correction results in a reduction in training time, which is almost 80% less. There is also little money saved on materials: the cost per student in the traditional way is almost 7 euros per hour.

For the time being, the Goierri Eskola is measuring the pedagogical advantages of the new system at this stage in order to know if the methodology is worth implementing in all welding studies. This experience is part of a project of the Goierri Eskola. It is a project that explores the advances and new forms of teaching in the world of welding and then disseminates them both in companies in the area and in other

educational centers. ALEJANDRO VILLARAN, seabery: The helmet. Following realism this is a real, commercial facial. What does augmented reality technology contain? This is an LED, the intensity can go up or down because augmented reality technology uses artificial vision and works with ambient light. We need to adjust the system to work better. Here are two high-definition microcameras to work on reality every moment. Virtual reality does not have microcameras, it does not see the environment, it operates in the virtual world. Well, what else? Video glasses that are the student’s monitor inside the face shield.

MIKEL AZKARATE; professor of metal construction: We'll do an analysis of what he's done. What you see is a video of the exercise he's done, the tremors are what he's done. This green list indicates the parameters that I have told you, it has come out at various times and that means that it has made mistakes. At the end it tells us that 85% did well and this generates competition among the students and that makes it attractive.

The teacher will collect the students’ work on their computer. All the exercises are recorded by the system, so that the application will indicate the evolution of each one: who makes the mistakes or if someone needs some special exercise.

ANDER HATER; student: It’s really like welding, it’s a nuisance, you see everything, how you’re doing, it tells you what position to hold,

it’s called the learning process based on augmented reality by the Andalusian company, augmented training. Theirs is not a welding company; although they started in welding and are already in 13 countries, the plan is to adapt this technology to be used in different areas and subjects of

teaching. ALEJANDRO VILLARAN, seabery: Imagine the model of a human mouth at the place of the welding test; the instrument of the dentist instead of torches. Where there is a lot of practice required to train the student and this practice is difficult, complex, expensive or dangerous, there, this technology can make a great contribution.

MIKEL AZKARATE; professor of metal construction: Another type of work will be created for us, this machine must also be fed, tabs must be created, and at the end the analysis data must also be interpreted. It will somehow reshape our work.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian