Paper

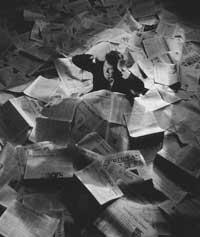

Then you have heard many times, reader, that the paper disappears. There are also those who say that will not happen. Before we make the leap into the future, we look at the past and the present. In fact, man learned to use paper long ago and today thousands of tons are spent daily.

Paper precursors

The Chinese invented the role in the first century after Christ. But we cannot say that our ancestors did not know until then any support for drawing. 3,000 years before Christ were drawn on clay tablets in Mesopotamia.

This support was very economical and of use. But it also had great disadvantages; it was uncomfortable to keep the tablets and it had to be quick when drawing, since once dry the clay was impossible to draw it. Faced with the difficulties of clay, our pioneers sought a new support: the papyrus plant.

This plant, abundant in the Nile delta, was a higher quality support than clay. The word paper comes precisely from the name papyrus. The use of parchment began shortly after the papyrus plant. They made parchment with calfskin and lamb and eventually managed to polish and whiten the thick material of papyrus.

The Chinese discovery

After the scroll, the Chinese managed to make paper, a support that is now everywhere and has become indispensable. The interior of the bark of deciduous trees called “white marugado” was used for this initial paper. The vegetable fibers extracted from the white marugo and the water were mixed to obtain the paste. This paste was shaped like a leaf and being wet it was allowed to dry for a while. Once most of the water was poured, the leaf was carefully picked up by the edges and hung from the wall to dry it completely in the sun.

Thus came the first role and for centuries it could only be used in China and its nearby territories. VIII. When in the mid-20th century the Chinese Empire began to expand westward, it unveiled the role in Islamic countries; in Damascus, Egypt, North Africa and Spain. In these places they did not know the paper derived from the white mating, but the esparto paper and the linen paper.

Paper conifers

The paper manufacturing process is long. Tree trunks, especially conifers and deciduous leaves, must become paper. Not all this tour is done as indicated above, that is, by manual procedure. Mechanical and chemical procedures are currently used in cup workshops. However, some factories still produce paper by hand for higher quality.

The first step to paper is the grinding of the stump chips. The ground wood is introduced into boiling water, obtaining a viscous paste. The glue is added to this paste, since when writing or otherwise putting the ink in it, the ink does not expand and is well defined. The glue is one of the many substances that are mixed in the paste to make paper. Every element that is mixed with the mass has its function. The dough passes through more than one sieve; sometimes this mixture is cleaned by some chemical element, sometimes it gives color to the paper, etc. Once properly treated the dough will form the leaf. The paper is wet and must be dried.

For this purpose it is collected in the cylinders and gradually dried. Now a final touch is given to this paper: total drying, calendering or pressing, ironing and satin, among others. This last step is basically to put the paper under the pressure of large solid metal cylinders. The paper will be removed collected in coils and then cut into different sizes according to needs. Although we don't realize it, we can find the paper everywhere and use it for everything.

Knowledge of the background and production of this highly appreciated material therefore seems important. But how long? Will we use paper again in twenty years? It has been announced that this everyday material will disappear (or at least be greatly reduced). If that is true, we will not need paper to write the letter to our friend. You will also read on the computer screen the magazine you have in your hands.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian