Explosion engines: Do the two times predominate?

The physical base of explosion engines is the second principle of thermodynamics published by Carnot in 1824. According to this principle, the thermal machine (for example, the explosion engine) must transport heat from the hot source to the cold to work. As a result, Jammes Watt manufactured a steam engine in 1767 and Lenoir, a gas engine in 1859. Later, Beau de Rochase thought about improving the performance of the gas that was going to burn with a previous compression. The German Otto finished this idea in the piston engine in 1877.

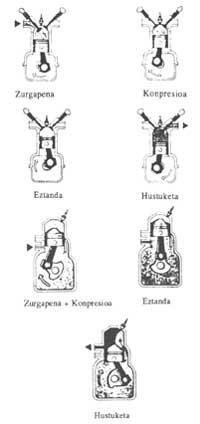

Since 1900, piston engines have been divided into two large groups: four-stroke and two-stroke engines. Around 1900 an engine was discovered that would replace the four-stroke engine with the two-stroke engine. In this new engine, there were no distribution systems, no valves, no springs, no camshaft. The motor is lighter, smaller and easier to manufacture.

Superimposed absorption and emptying, the motive force is collected in each half-life of the crankshaft in the two-stroke engines and in the four-stroke engines in two laps only in the middle.

As for performance, the two-stroke engine has its disadvantages (otherwise cars would not have four-stroke engines). On the one hand, when the piston is down, the burnt gases do not go completely through the exit window and access a little to the window that comes the cold mixture. In turn, the cold mixture tends to come out directly from the exhaust window without filling the cylinder. This means an increase in engine consumption and greater contamination of emitted gases.

In addition, two-stroke engines for thermodynamic research are more difficult. Simulating in turbulent conditions the burned gases and the evolution of the cold fuel mixture is impossible in two-stroke engines.

But Australian engineer Ralph Sarich has introduced many improvements to the two-stroke engine. Mr. Sarich was invented in 1973 as a special explosion engine. It had a rotating central piston but not a Wankel type, but it formed a kind of orbit. With the award he won he then formed an explosion engine research association.

First of all, his “orbital” engine began to work, researching and developing the direct injection system to improve its performance. The injection system is pneumatic, similar to the large diesel engines of ships. Compressed air is injected into the combustion chamber by spraying the fuel. It is therefore a two-fluid system that functions as a paint gun.

The pneumatic injection developed by the Sarich team had two objectives: to improve performance and reduce exhaust pollutants.

But the surprising thing is that the system gets the best performance in two-stroke engines. Because in addition to gaining power, it greatly reduces consumption. That is why now all research is being conducted on two-stroke engines. The system of Mr. Sarich collects all the necessary organs in an injection manifold: piping, dosing, feeding, electronic control, etc. In the first trials an independent air compressor was used, but now the necessary pressure is taken directly from the combustion chamber thanks to six perfectly calibrated holes.

The necessary pressure in the cooking chamber is not high, but about five bars. At this low pressure it is easier to control the delay of the injection (necessary to improve the performance) and you can load the mixture to the stream “stratified”. The swirl generated when filling the cylinder is used to obtain layers of different concentrations of fuel (something similar to geological strata). The richest layer of fuel is next to the spark plug and the poorest layers are the furthest away. When exploited in this way, the engine performance, consumption and composition of the output gases are improved.

The injection governed by electronic sensor has prevented the cold mixture from leaving the escape in two-stroke engines. However, there are other obstacles such as lack of momentum at low turning speed, unstable “idle” and high lubricant consumption.

To improve the problem of the moment, Sarich has installed variable section windows. A rotary valve allows obtaining the most suitable section at any time. On the driveway some floating sticks open in the carpentry and are collected at the time prior to compression. Thus, the moment has risen from 90 Nm to 135 Nm between 1000 and 6000 rpm. The result has been better than in 4-stroke engines. Also, the variable geometry of the exhaust window has allowed stabilizing the “idle”. As for the consumption of lubricant, in the Sarich engine the fuel is not in contact with the crankcase and the gasoline does not mix oil as in normal two-stroke engines (this gasoline oil then contaminates the output gases). The lubrication is done with extra pump in the Sarich engine and from 2500 km approximately one liter of oil is spent.

In general, this engine has more advantages than current cars. On the one hand, it has easily passed the most demanding American tests against pollution and, thanks to it, does not need reducing catalyst for exhaust gases. This saves half of the exhaust system. On the other hand, the engine power is very different. The Sarich engine, with a displacement of 1.2 liters, gives a power of 91 horses and weighs 41 kilos. On the other hand, any engine of the current four times, with a displacement of 1.6 liters, reaches a power of 85 horses and weighs 128 kilos. In the Sarich engine, vibrations are lower, accelerations are better, consumption is reduced by 10% to 20%, etc.

For the moment, Ford and General Motors are testing this new two-stroke engine and within a few years their dominance will not be surprising.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian