Order atoms to perform hard disk nanomagnets

2013/05/24 Roa Zubia, Guillermo - Elhuyar Zientzia Iturria: Elhuyar aldizkaria

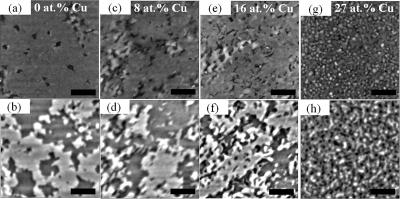

Iron and platinum are an alloy suitable for nanomagnets, but requires high temperature treatment. Not very effective. But researchers at the University of California have found a solution that has been published in the journal Journal of Applied Physics. The addition of copper atoms to the alloy allows to order the atoms of the nanomagnets without having to perform the process at very high temperature. The magnetic hard drive industry is also making a great effort to make magnetic hard drives smaller. To do this, they must reduce the areas that are magnetized in the material on the disc, that is, perform nanomagnets. The alloy processing procedure is, in principle, the manufacture of iron and platinum nanocerubos. They do it in hot so that the two metals mix and their difficulty lies in correctly ordering the atoms. The University of California has found a two-step solution. First, they add to the alloy small amounts of copper atoms, whose presence makes iron and platinum order, generating nanomagnets. Subsequently, the material is subjected to a rapid cooling process. The addition of copper atoms prevents manufacturing at very high temperature, but, although to a lesser extent, it requires the heating of the alloy and rapid cooling so that each atom remains in its corresponding place. The result is a material made up of very small magnets, ideal for making hard disks.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia