Technological failures and accidents

1987/02/01 Rodriguez Ibabe, Jose Maria Iturria: Elhuyar aldizkaria

Last year there have been numerous and harmful high-tech accidents. At first, the Americans lost the "Challenger" launcher; then two rockets of those used to propel satellites, the so-called Titan and Delta, exploded. The Soviets had Chernobil.

To know to what extent the negative effects of these accidents have arrived, time must be long. At the moment, there are the seven months, the economic costs of the launcher loss, the paralyzation of the space project (we must take into account the war of the galaxies), the disqualification of some leaders of the platform, etc.

On the other hand, the serious accident of the Chernobil nuclear power plant has again put into question the peaceful use of nuclear energy. In this case, despite not being exhaustive, there have been many dead and wounded, the economic damage has been very important and, perhaps for the first time, the consequences of the accident occurred within a state have been noticed in most European states.

And to complete this dark panorama we will have to say that the launcher "Ariane" has fallen to the Europeans. Due to this accident, the deficiencies of the Ariane space project have increased up to 20%.

However, even though all these cases are very noteworthy, because we had the opportunity to watch live the accident of "Challenger" through television, we have to think that since the beginning of the industrial revolution there have been many accidents.

If we make a list of accidents, we will realize that the origin of almost all of them can be divided into three types:

- design manufacturing design

1.- Design

In the first group, errors due to poor design of the apparatus are investigated. Sometimes the data is calculated by mistake or simplicity, and others by not taking into account all the possibilities.

Of the serious accidents caused by the design we have many examples, more than in the last century. For example, with the creation of the railway, there were cases of accidents and deaths of people, especially due to the breakage of the axes and wheels of the train. In the sixth decade of the last century about 200 people died in Britain every year "thanks to the train". In most cases the problem was "material fatigue", an unknown phenomenon that appeared in dynamic pieces. The technicians calculated the wheels and shafts as if they were static parts, regardless of intermittent loads appearing reducing the mechanical resistance of the material by the movement of the train. Consequently, these pieces were broken, and on several occasions the train was leaving the track.

Another closer example with nefarious consequences, especially for the number of deaths and market loss, is the British plane "Comet". After 300 hours of air testing, in May 1952, for the first time, the commercial jet plane (until then all were military) began to be used by the English. In 1954 a "comet" fell to the Mediterranean Sea, although four days earlier it had smoothly overcome technical controls. Due to other accidents, those responsible decided to remove all "Comet" aircraft that were being used in the world and named a commission of investigation.

The following design error was detected in the study: when the plane was in the air, a very high concentration of mechanical stresses appeared in the vicinity of the windows, so occasionally some windows were broken in flight. After completing the investigation, the "Comet" model was removed and the good British aeronautical reputation was quite buried. Thanks to this, the United States found no competition to sell its planes through Europe.

To finish, we will mention what happened with the boats "Liberty" during World War II. The Americans had to increase the productive capacity of transport ships to send weapons to the European allies. At that time, the main element was the bonding rivet of metal plates in the construction of ships, but with this procedure it took a long time to the launch of the ship. For this reason, the technicians considered it necessary to replace the rivet system with another new one.

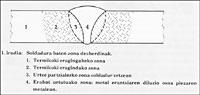

This system was welding, but after this change there were harmful and incomprehensible effects. Of the 2500 ships built "Liberty", 145 were broken into two parts (most when towing) and another 700 were seriously damaged. In this case, the technicians did not take into account other factors by welding without modifying the design. For example, the first, that the welds have the capacity to make the material more fragile and the second, that throughout the procedure there are gaps or defects in the pieces.

With the investigation of these accidents and similar a new branch in the field of mechanics has been developed. This section is called fracture mechanics and currently it is not possible to build large metal structures (ships, bridges, planes, etc.) Without taking into account the bases of the mechanics of fracture in the design calculations.

2.- Manufacturing

As for manufacturing, we take into account the defects in the manufacture of parts and the lack of quality of the material used. To eliminate this type of accident, the workshops have quality control departments. When analyzing any material purchased for the manufacture of the parts, the workshop checks whether the material sent to you by the supplier meets specific requirements. On the other hand, when controlling the products that leave at the end of the plant, the seller analyzes whether they have a minimum quality or not. If they do not meet the minimum fixed by him, the pieces are rejected.

However, despite overcoming so many controls, accidents and economic losses are frequent. On the one hand, because it is very difficult to control everything, and on the other, because the economic pressures of reality are high, many times everything is done of pieces badly made by selling.

To defend the rights of the buyer there are guarantees of purchase. If there are manufacturing defects in a product, they will appear in the first moments of its use. Therefore, through veracity, errors that have not been found in the quality control of the workshop can be corrected. In other cases, when the social obligation of the product is important, the consequences of malfunction are unacceptable, since people's lives are in danger. The case of a steam boiler in Bizkaia in the past decade is an example of these beginnings.

3.- Utilization

We have defects due to the misuse of products. Although the pieces are well designed and manufactured, safety limits should not be exceeded in their subsequent use.

A few years ago, the case of "Los Alfaques" in Spain is an example of this. In that place the tank truck explodes with more than 200 dead. After the investigation it was publicly commented that the truck was overloaded.

Another example we have in our cities. Many times, when a celebration takes place in the streets during the patron saint's holidays, people do anything to find a place, for example climb the decks of the bus stops. If we take into account that these refuges are not designed to withstand so much load, it is normal that occasionally an accident occurs.

In this article we have divided all accidents into three groups, but in our daily reality things are much more complicated and sometimes the accident is not only for one thing, but for a chain of errors.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia