Magnetoelastic sensors: detection method of external agents

2020/05/14 Andoni Lasheras Aransay - Euskal Herriko Unibertsitateko irakasle atxikia Fisika Aplikatua I Sailean | Paula Gonzalez Saiz - BCMaterials Ikerketa Zentroko Ikertzailea | Ana Catarina Teixeira Lopes - CIC Energiguneko Ikertzailea Iturria: Elhuyar aldizkaria

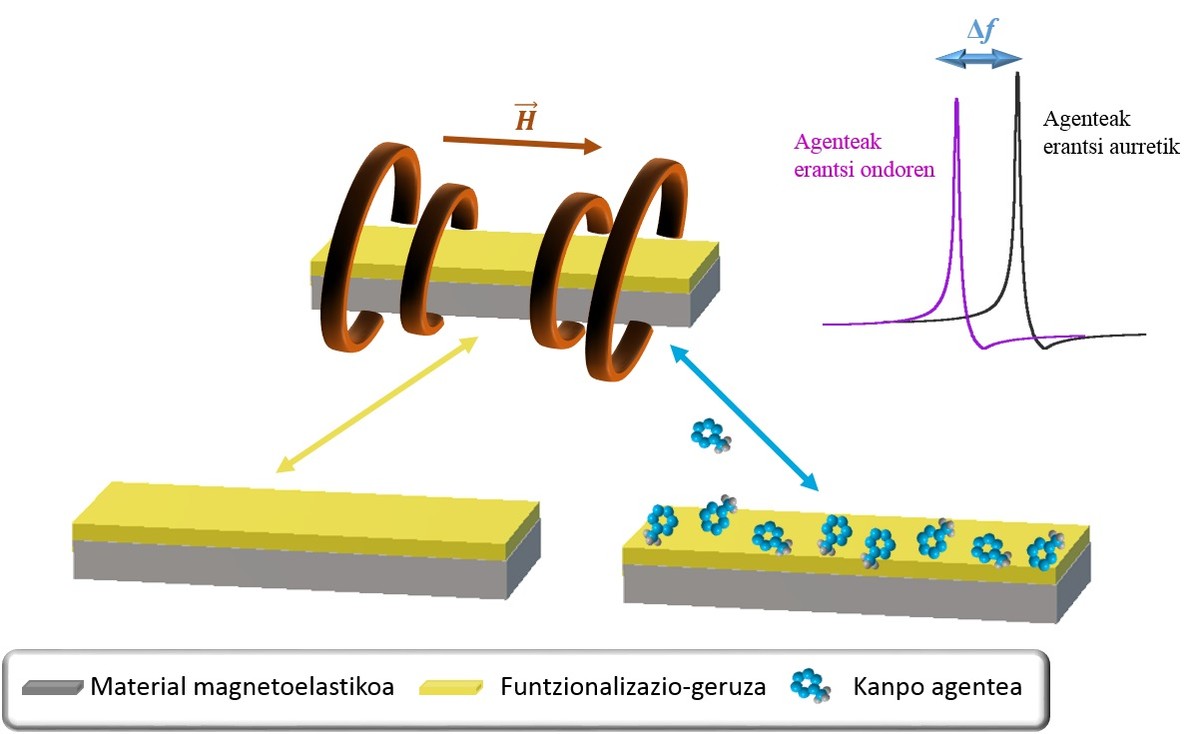

The elastic properties of magnetoelastic materials vary under a magnetic field. These materials are usually ferromagnetic alloys formed by iron and/or cobalt, in the form of rectangular tape. In addition, they are resonant systems when applied a magnetic field and have a resonance frequency of their own. This frequency varies under the influence of parameters such as temperature, pressure or mass change [1]. This last parameter is the one that allows detecting external agents. The addition of biological or chemical agents on a magnetoelastic material will generate an additional mass that can be detected by a decrease in resonance frequency provided that the magnetoelastic material presents a sufficient sensitivity. This process, logically, is not simple and requires the previous functionalization of the surface of the magnetoelastic tape.

The functionalization of magnetoelastic materials consists of providing these materials with the necessary capacity to detect an external agent. Depending on the external agent you want to detect, one or another method of functionalization is used, but the objective is always the same: “catch” the biological or chemical agent. If bacteria are wanted, for example, phages or antibodies are used, among others. Gas detection is usually carried out through zeolites or MOF (Metal–organic framework in English, metal and organic structures) which, due to their porosity, have the capacity to absorb gases.

The shape of the sensor is important in the sensitivity of detection

As has already been indicated, for the detection of external agents, it is very important to obtain high sensitivity magnetoelastic materials, that is, when adding a quantity of mass, there are significant changes in the resonance frequency. This process has been based so far on reducing the size of the magnetoelastic material. In general, the smaller it is, the more sensitivity is achieved by magnetoelastic sensors. However, reducing magnetoelastic materials can cause problems. On the one hand, they are much more difficult to use and, on the other, there are fewer active surfaces to detect external agents. Therefore, it is necessary to achieve a balance between usability and size to achieve a suitable sensor.

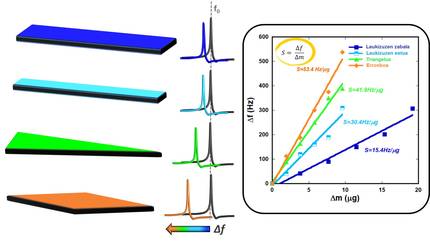

Therefore, to improve the sensitivity of magnetoelastic sensors, it is essential to investigate other alternatives. One of these options is to change the appearance of magnetoelastic tapes [2]. Of course, it is not easy to make magnetoelastic with different shapes. It requires a lot of precision to achieve an adequate appearance and that the results obtained are reliable. For this purpose, from conventional rectangular tapes, pulsed laser beams are applied for the manufacture of sensors of suitable dimensions and shapes. In fact, it can be observed that, using the same active surface, important improvements in sensitivity are observed when using rectangular tapes closer than conventional ones and magnetoelastic tapes in the form of rhombus or triangle.

Specifically, from magnetoelastic sensors of different forms, the rhombus is the one that presents the highest sensitivity to a change of mass. For example, in 12 mm long sensors, when adding several layers of gold, the rhombus sensor is able to detect a change of 53.4 Hz per microgram. This means an improvement of almost 250% in the sensitivity value compared to the conventional rectangular sensor, in which a variation of 15.4 Hz per microgram is seen. Therefore, the sensitivity of magnetoelastic sensors can increase considerably by changing their geometry.

Detection of external agents

We know, therefore, that the best sensors for the detection of external agents are magnetoelastic materials in the form of rhombus. In this sense, it is necessary to analyze its response to external agents to know its effectiveness. For this purpose, two experiments have been carried out for the detection of isopropanol gas using a rhombus sensor with the same active surface and another rectangular shape sensor. In these experiments, MOF has been used for the functionalization of magnetoelastic tapes, which have a large capacity of isopropanol gas absorption.

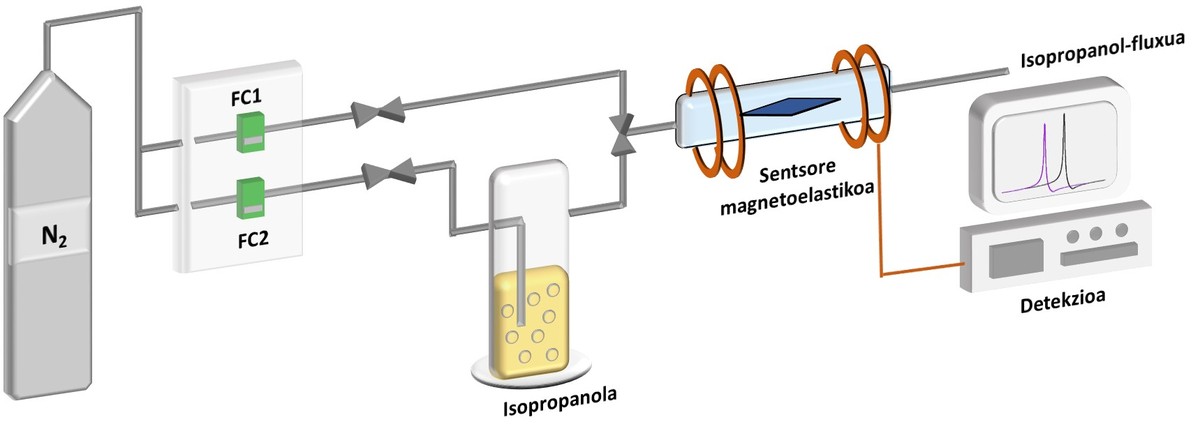

To carry out this process we have mounted a gas system in our laboratory. This system consists of a bottle full of nitrogen and through a system of valves the gas flows are controlled: the flow of nitrogen on the one hand and the isopropanol on the other, is passed through the space in which the magnetoelastic sensor is located, under a magnetic field. Note that the MOF used in the sensor does not absorb nitrogen.

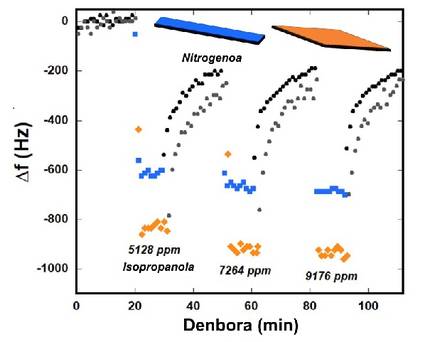

Therefore, the variation with the time of the resonance frequencies of the two sensors dependent on the magnetic field of 15 Oe, according to the concentration of isopropanol, has been measured with rectangular and rhombic tape. The results show that magnetoelastic materials are capable of detecting isopropanol gas. In fact, in the two cases analyzed, a difference of at least 500 Hz has been measured when isopropanol gas has been subjected to sensors at a resonance frequency.

In addition, when the isopropanol concentration (from 5.128 ppm to 9.176 ppm) changes in the resonance frequency are observed. That is, the magnetoelastic sensors are able to detect also small variations of flow. As for the shape of the magnetoelastic materials, the results obtained show that the sensor in the form of a rhombus is more capable of detecting isopropanol than the rectangular one. In fact, in all concentrations of isopropanol, the variation of the resonance frequency measured in the rhombus sensor is 33% higher than the rectangular one.

Therefore, it is clear that magnetoelastic sensors can be used to detect external agents. In addition, it has been concluded that the shape of the magnetoelastic sensor is also determinant. In the field of public health, it is clear that it is necessary to develop new, precise and cheap methods of detection of external agents, and our objective is to present the magnetoelastic materials as a new opportunity in this tour.

Bibliography Bibliography Bibliography

[1] R. Banu Priya, T. Venkatesan, G. Pandiyarajan, Haresh M.Pandya. 2015 “A Short Review of SAW Sensors”. Journal of Environmental Nanotechnology, 4, 15–22.

[2]P. G.Saiz, D. Gandia, A. Lasheras, A. Sagasti, I. Quintana, M.L. Fdez-Gubieda, J. Gutierrez, M.I. Arriortua, A.C. Lopes. 2019. “Enhanced mass sensitivity in novel magnetoelastic resonators geometries for advanced detection systems”, Sensors and Actuators B: Chemical, 296, 126612.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia