Machine tool: two words of wide use

2000/03/01 Carton Virto, Eider - Elhuyar Zientzia Iturria: Elhuyar aldizkaria

Simply hearing the words machine tool will frighten some, arouse interest in others and even captivate someone, but the machine tool influences everyone's life. According to the definition of the vocabulary, the machine tool "is an apparatus that gives the raw material the necessary form through a suitable tool of movement and force". They shape unworked parts or sheets (steel, casting, plastics, wood, etc. ). The material is cut, broken, perforated or folded using its own tool and all these machined are the result of the tools and components we use daily. The components of the cars and the cars themselves are manufactured by the machine tools; the small components of the mechanism of the watches are manufactured by the machine tool; the mold for the manufacture of the plastic housing of the radio recorder has been made by a machine tool.

In the Basque Country, 2,000 machine tool models are manufactured, some of the size of the beautiful living room desk, giant buildings weighing hundreds of kilos. Machine tools can be classified according to different criteria and placed in lathes, milling machines, boring machines, grinding machines and drilling machines. But for those who miss all these words, the first thing is to know what these tools are and for what. Our classification is based on the machining carried out by the machine tool and is divided into two large groups: machine tools that work the raw material by cutting and starting chip and machines that work the raw material by deformation. The first group groups the machine tools that drill, cut, scratch, flatten, etc. the raw material and the second, the machine tools that bend, retain and work the raw material under pressure.

World Novena

The machine tool industry is an important sector in the Basque Country. Most of the state companies are located here, both historically and today the region that has concentrated most of the companies in the sector has been Bajo Deba. Alberto Ortueta was born, an entrepreneur who for the last 28 years has served as director of the Association of Machine Tool Manufacturers. From birth it is elgoibartarra and smiling that carries the machine tool in blood. "The association was born in 1946 and we are currently in the Miramón Technological Park. In general, the objectives of the association are to promote the development and competitiveness of the sector." 96% of the companies in the machine tool sector are members of the association and together with 13 other European associations are part of the CECIMO (European Commission for the Cooperation of Machine Tool Industries).

Our machine tool industry is the 9th in the world, the 5th in Europe in production and the 8th in the world in exports. In the last 10 years, 56% of production has been sold in 120 foreign countries, 70% to countries with high levels of industrialization and technological development. Germany, the United States and France are respectively the most important buyers and, according to Alberto, "this is due to the level of quality and denomination of our products. In addition, this export trend has been maintained over the past 12-15 years, ensuring that our products are competitive, otherwise we could not maintain that export level for so long."

And how have they reached the level of our machine tools? "The machine tool sector has changed a lot in the last 40 years," says Alberto. "In the 1960s, for example, the machines here manufactured were based almost exclusively on foreign technology. Here the machines were made by agreements or copying. Currently, the fingers of one hand are enough to count on the 2,000 models that are manufactured using foreign technology. The machine tools we manufacture today are based on the technology developed by us and that cannot be said by any country."

The importance given to research has to do with the level of the machine tool sector in the Basque Country, since 5% of the money that is billed annually goes to research. This allows each year new machine models or improve existing ones. "The Basque Country has good research infrastructures. The Technology Centres contribute significantly to all areas of research and, in addition, the Basque Government, the State and Europe have specific plans to foster cooperation between companies and countries. In fact, we are a competent association called INVEMA. In addition to the coordination of the research departments of the companies, INVEMA monitors the patents that are carried out at the European College, the United States and Japan. In this way we can know the line through which international research runs and see whether or not its elaboration is applicable to our machine tools. In any case, the machine tool is a highly internationalized sector and any advance in numerical control that occurs in Japan is maintained for a year by our machines." The consequence of all this is the obtaining of highly technological products, at the same level as other powers of the sector.

Given the positive data of recent years, it can be said that the harsh crisis of the early 1990s is a reality. Since 1995 production has grown steadily and Alberto believes that this year does not have to be a bad year. "The year 1998 was a very good year and production increased significantly, 18% compared to 1997. However, 1999 was a difficult year. On the one hand, the crisis in Asian countries hindered exports, as Asia is a very important consumer of machine tools, and on the other, the level of consumption in the United States decreased by 20%. All this meant a decrease in demand, but thanks to the accumulations of previous years, we increased both production and export, 7% and 5% respectively."

Although in general it was a difficult year, in 1999, for example, the state machine tool sector recorded a higher level of production than Britain (30 years ago it was unthinkable) and, in addition, production increased twice the European average. Alberto Ortueta is quite optimistic about the year 2000 "the economic indicators indicate that the economies of the main European countries will continue to grow, in the United States the consumption of machine tools is growing again and the Asian countries begin to emerge from the crisis. In addition to this positive data, this year we will have two important exhibitions: One at the Bilbao Biennial and one in Chicago in September. Therefore, we believe that in this year 2000 the sector is consolidated and slightly increased”.

Speed and security

The machine tools we currently see in exhibitions and companies, and the images that make up the article, have broken the classical ideas about these tools. Many of them are closed rooms, fully computerized and with a high level of security.

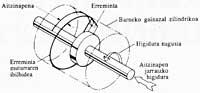

Under the name of numerical control, XX. In the middle of the 20th century came the computer revolution to the world of machine tools. The revolution took place in 1949, by the hand of the American John Parson, who made helicopters. The numerical control selects and controls the position, direction, travel speed and direction of each piece and tool, adding intelligence to the machines. In the 1970s, numerical control became a computer numerical control and paved the way for "intelligent" robots capable of performing several pieces at the same time or facing problems that arise at any time.

As a result of numerical control, machining centers appeared: milling, drilling, tapping and boring, a machine capable of performing all these machining jobs. Instead of milling one machine, drilling the other, boring the other and threading the following, the machining center does everything and you don't have to move the part from one machine to another.

Numerical control has offered numerous advantages to machine tools: flexibility, speed, precision, safety and a wide field of research. 76% of the machine tools currently manufactured in the Basque Country operate by numerical control, but much remains to be investigated. "In the field of chip starting machine tools, speed, ecological machining and safety are the lines of research," explains Alberto Ortueta. "High machining speeds are already a reality. This type of machine tools is used in many companies, although it is not possible for all customers. Machine tools operating at high speed increase production, but it is also necessary to change the machines. The high speed produces friction and heat on the one hand, and on the other, when the movements of the parts and tools are carried out very quickly, the inertia generated causes problems when stopping the movements. One of the main lines of research is the resolution of these problems."

Ecological mechanization is another important research topic, although much remains to be done in this field. Cutting the raw material is often done with oils that generate fumes and vapors. On the other hand, used oils must be recovered. All of them generate ecological problems, so the studies are focused on cutting techniques that do not use any type of oil.

The third important research topic is machine tool safety. "The safety standards of the EU machine tools are the strictest in the world and we have made a great effort to ensure that all the machines manufactured here meet these standards. Today it can be said that the goal is achieved and that almost all our machines comply with EU standards." Many of the machine tools currently manufactured are completely closed: the tool and structure of the machine is surrounded by walls, like a room, and the walls are closed while the tool works. Security is based on machine structure and not on user skill.

As for machine tools that work by deformation, high speeds are also important, but there are other technologies. Also in this case, speed increases production and rationalizes it. "In many companies the production mode is currently used just in time. When changing dies and machine components took a long time, a machine made the same piece non-stop. The speed allows to accelerate these changes and make only the necessary parts. Suppose we have to make 100 cars in one day and each car is made up of five different pieces. The “just in time” work means that one day 100 units per piece will be made and that unnecessary pieces will not be stacked. So, for example, we don't need a warehouse. But if you can work like that, it's because making a machine one piece to another takes less time."

According to Alberto Ortueta, the novelties to be seen at this year's Machine Tool Biennial will be based on the general lines mentioned: speed and safety. However, it is very difficult to say what is going to be seen until the opening of the exhibition, since machine tool manufacturers keep the news secret in order to generate a better impression on the exhibition itself. The exhibition brings together many buyers and is a showcase for many

companies.

XXI International Machine Tool. the biennium (BIEMH'2000) will take place from 13 to 18 March at the Bilbao International Trade Fair. Organized by the Bilbao Trade Fair and the Association of Machine Tool Manufacturers, the biennial is one of the most important exhibitions in the sector in the world, reflecting the importance of the machine tool industry in our country.

The first machine tool exhibition was held at the Bilbao Trade Fair in 1961 and has become a more important event of the event. CECIMO, a national association of 14 countries in the sector, brings together the European Commission for the Cooperation of Machine Tool Industries, which approved the BIEMH exhibition two years ago. In the 1996 session the organizers moved the exhibition to March which was held in October. The change was proposed so that the Bilbao exhibition did not coincide with other exhibitions held at those times in the world, which has made this biennium of the machine tool the first chronologically in the world.

More than 1,700 exhibitors will meet in Bilbao, of which 1,100 will be foreigners. These data reflect the prestige and international relevance of the exhibition. "In addition to the EMO exhibition organized by all European associations, the most important exhibitions are the United States and Japan, but ours is at the head of the individual exhibitions organized by European countries." It is as big as what is done in France and this year it will occupy all the space that the Bilbao Exhibition Centre has. In the words of Alberto Ortueta, "this year we will fill the 42,000 square meters that the Bilbao Fair of Samples has, but the fair has already remained small. For lack of space, some exhibitors who wanted to be here have been left out." Alberto Ortueta believes that if the fair were wider, this year they would cover between 45,000 and 46,000 square meters of machine-tools, which would allow to significantly exceed the exhibitions in France and Britain. However, the XXI. The biennium will be the most important of the last year in technology.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia