Liquids, solids... or both?

Lubricants facilitate and reduce the movement of components, reducing friction between pieces. This is why oil is added to the motor of the car or to the chain of the bicycle, so the hinges or bands of the doors of the house, as well as the motor of the washing machine, have oil.

However, lubricants often have to work in different conditions over time: now with the parts moving fast, then with the slower parts, hot, cold, dry, wet or mixed with other liquids. All this can imply a transformation of the characteristics of the lubricants, especially a change in the viscosity, which can imply a change in the efficiency of the lubricant.

That is why lubricants have been invented that can work in a wide range of intelligent conditions and lubricants, that is, lubricants that respond to external stimuli. For example, heat makes the lubricants tuned by themselves, but a certain external influence can be achieved and the lubricants are again more viscous.

Mouinir Bou Ali and his team investigate smart lubricants at Mondragon Unibertsitatea. In particular, lubricants that become more or less viscous depending on the magnetic field.

These fluids are called magnetorreological, that is, fluids that vary their reology or properties depending on magnetism. In this case, its viscosity or viscosity is modified. This property is obtained thanks to the magnetic microparticles added.

Three components

The fluids used for research consist of mixtures of three components: the fluid depending on the application, in the case of lubricants, some oil; the magnetite, which will provide a differentiated behavior according to magnetism to the mixture; and the surfactant, so that everything is stable and homogenously mixed.

Solid liquid solid

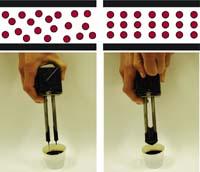

By submitting magnetorreological fluids to the magnetic field the viscosity is changed: they become more viscous, many times to become almost solid. This is possible because magnetite particles create chemical links with the fluid lubricant and surfactant. If there were no links, only magnetite particles would react.

Somehow, all the particles that form the fluid are homogenously mixed, but without order. However, under the influence of a magnet, magnetite particles and, therefore, the rest of the associated particles are ordered. The fluid becomes more viscous.

In addition, the particles of the fluid approach one another depending on the type of component and the zone, increasing the compaction of the fluid. It depends on the strength of the magnetic field and the characteristics of the mixture, but the fluid can also adopt the shape of a solid: the container is placed face down and does not flow at all, or the fluid can adopt the shape of a crown when compacted following invisible magnetic lines.

Applications in washing machines...

In addition to studying how to prepare and its properties, Mondragon Unibertsitatea studies the possible applications of this type of fluids.

For Mouinir Bou Ali, leader of the research group, "the advantage of having some controlled variable is enormous and, in this case, the advantage is to control the fluid through magnetism against conventional lubricants". For example, heat can fine-tune the lubricant and limit its efficiency, but if a temperature sensor activated a magnetic field and therefore the lubricant was more viscous, then the heat problem would be overcome.

At the University is being investigated in the field of lubrication and shock absorbers. It is working especially with washing dampers.

Dampers with magnetorrheological fluid are placed in the washing machines and their result is analysed in certain vibration frequencies to compare it with the results of conventional dampers. This aims to improve the magnetorreological fluids and optimise them for this specific application.

...and liquid mixtures

Another of the areas of application is the transport or storage of any fluid, and in particular of the mixtures.

In fluids containing more than one component or solid particles, the precipitation of some of its components can occur. But in Mondragon Unibertsitatea it is believed that the breaking of components can be avoided. This can be achieved mainly through pressure, but also by applying magnetism. If the precipitated component has associated magnetite particles, it is intended to apply the magnetic field and avoid precipitation.

However, it may not be convenient to use the magnetic field for the homogeneous distribution of fluid particles, or not to do so. In these cases, it is possible that the magnetite itself and the particles associated with it precipitate, so it would not be possible that the viscosity would be altered arbitrarily with the application of the magnetic field.

It is a question, therefore, of solving this problem through the temperature: the application of the heat only to one side or only in certain points generates a convection traffic in the fluid, which allows to obtain a homogeneous distribution of the magnetite to later obtain the desired reological variation with magnetism.

Therefore, external conditions can give rise to the response of magnetorreological liquids as a result of the activation of the magnetic field, but in some cases this external factor may be necessary for the response of the fluid to be adequate when the magnetic field is applied.

Liquid washers and mixtures are the two main applications that are being investigated in Mondragon Unibertsitatea, but magnetorreological fluids have already begun to be used in shock absorbers, clutches, brakes, valves, some applications of robots, etc. In the building of the Museum of New Sciences and Technologies of Japan, dampers have been installed with this fluid to combat earthquakes. Also on the cables that hold the bridge of China's Dong Ting Lake, so that it moves less when the wind blows strongly.

In the end, we like that the washing machine seems less vibrant and to rummage or that the car is softer, or that the pedals of the bicycle go very fast, right?

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian