Fast, precise and comfortable

2000/04/01 Carton Virto, Eider - Elhuyar Zientzia Iturria: Elhuyar aldizkaria

From 13 to 18 March, XXI International Machine Tool. A biennium was held at the Bilbao Trade Fair in which all attendees enjoyed a great show. Elhuyar was also present to inform you of the latest developments of companies in the sector.

XXI International Machine Tool. Last March, the biennium brought together 2,017 exhibitors and thousands of visitors, both professional and amateur, at the Bilbao Fair. In this year's edition the participation has grown by 16% and 12.5% on the surface, since the Bilbao Exhibition Centre has remained small in machine tools. Milling machines, lathes, robots and presses occupied all the space offered by the fair. The organization told us that the corridors had to be tightened and, however, it was not enough, since they had requests to occupy another 2,000 square meters. The machine tool is in need of a new trade show, larger and with adequate access.

But aside from the debates, there was something to see and learn at the Machine Tool Biennial. There were 2,017 companies exhibiting novelties that, with their local peculiarities, became the most outstanding novelties in terms of speed, design and ergonomics. Fast work has become in recent years the symbol of machine tool manufacturers, which makes faster movements to perform, but without losing precision and reducing the times of change between part and tool. Many of the exhibiting machines offered the possibility to do two things at once: the part change is done while the tool works another part, thus reducing the loading/unloading time. Making as many parts as possible, with the highest quality, but in the shortest possible time, is the goal of any current machine tool.

But the need to work fast has problems like inertia. Faced with inertia and involuntary movements of parts and tools, machines require light structures, and the company Fatronik de Elgoibar presented a proposal to avoid the problem: machine tools built through the network. The network system is widely used in architecture, as is the case with the Eiffel Tower. Fatronik has applied this same technique to machine tools obtaining lighter, more flexible and cheaper structures than conventional ones. The technique can be used, for example, for machine support. Instead of being compact and heavy castings, we would have light components of bars and knots in the support. Easier and cheaper parts to manufacture, but without losing a pinch of rigidity.

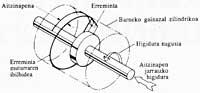

Fatronik also presented the ULISES I milling machine and the machine that is still a prototype caused great expectation in visitors. The most remarkable novelty of this milling machine is the movement of the tool, consisting of three arms that form the pyramid, with the tool at the tip of it. The three arms to move the tool from left to right, from top to bottom or from back to forward are stretched or shortened simultaneously, obtaining the precise movement to work the piece. Although the machine seems very complex in appearance, its construction is simple. In addition, it opposes rigidity, high working speeds and price, cheap for its properties. For all these characteristics he presented himself to the I National Design Prize ULISES and received a special mention from the jury.

Important aesthetics

In this edition and in previous editions, it highlights the importance it is giving to the design and exterior aesthetics of modern machines. Fully aerodynamic looking machines have taken over the old compact, green machines. In the 1990 edition was born the National Award for Machine Tool Design, which, as its name indicates, rewards and stimulates the creativity of authors in design. The awards are organized by the DZ Design Center in collaboration with AFM and BNE and are sponsored by the Department of Industry, Commerce and Tourism of the Basque Government and the Ministry of Industry of Madrid. In addition to the design, the jury selects the winner based on the importance and technology given to ergonomics, that is, the comfort of the operator who will use the machine. In this edition, 12 companies competed, 9 in the chip boot category and 3 in the deformation category. It should be noted that 11 of them are companies located in the Autonomous Community of the Basque Country.

Ona Electroerosion S.A. The Durango company's ARION K500 thread erosion machine was this year's winner in the chip starter category. This machine, thanks to its design, is able to work very large parts (very interesting for the automotive industry). When working large pieces, due to their weight, there were movement problems that were solved instead of moving the table on which the piece is placed, it remains fixed and the tools move. In turn, ARION K500 has a used and modern numerical control system. Together with ARION K500, Ona presented the ARION K1000 award. It is a machine tool that works the same, but bigger, the largest in the world at its level. Winning the prize has not been a coincidence, creativity is one of Ona's hallmarks and the 1998 edition also mentioned the jury.

In those who work for deformation, the company Gamei de Arrasate was awarded by the screw press PHSW-830: press that works at high speed by shock. The novelties are many, but especially in the design of the press PHSW-830 has focused on the safety and comfort of the employee. All areas of impurity accumulation have been closed, maintenance has been simplified, sound has been isolated and machine operation has been automated. Gamei has completely restored the screw press.

In so few days it seems very difficult to do business, but it is not the goal of the biennium. Machine tool authors gathered at the Bilbao Trade Fair to show, see and learn. Getting new relationships, seeing old friends and reflecting on what others are doing here and there is what needs to be done at the fair, you always have to learn from what the contestant does. Exhibitions such as Bilbao are often very important due to the economic impulse they give to the sector, since what is presented in it increases the economic implantations.

These kinds of meetings intensify trade and, since this year's exhibition is a cutting-edge and successful exhibition, you can expect the fruits to be the same. The deputy director of the Association of Machine Tool Manufacturers told us that "last year was quite cold, but we believe that this year will be better, not to start dancing, but better. The atmosphere we have seen in the exhibition also leads us to this conviction."

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia