New piezoelectric polymers

2007/12/01 Etxebeste Aduriz, Egoitz - Elhuyar Zientzia Iturria: Elhuyar aldizkaria

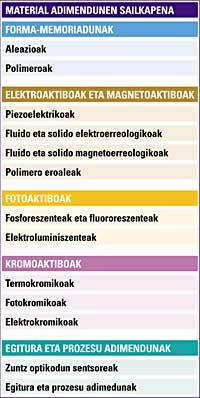

Piezoelectricity --pressure electricity, is the electrical polarization that is generated in a material by a Greek mechanical tension. This phenomenon is known as direct effect or generator effect and is mainly used in the manufacture of sensors (microphones, ultrasonic sensors, etc. ). ). But the opposite also happens with piezoelectric materials, that is, the reverse effect or motor effect: an electric charge produces the mechanical deformation of the material. Therefore, piezo materials are also used in actuators. They are very useful, for example, in those cases where high precision movements are required, since by means of electrical signals the deformation of piezoelectric materials can be controlled with micrometric precision.

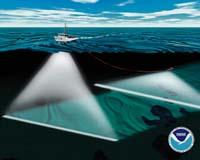

Piezoelectricity was discovered by the Curie brothers in 1880. Some crystals, such as quartz, showed a direct piezoelectric effect. However, until the beginning of World War I there was no practical application to piezoelectricity. At that time, French physicist Paul Langevin developed ultrasonic submarine detection sonar using quartz as a piezoelectric material.

The successful use of piezoelectricity in Sonar gave a great boost to research in piezoelectric materials. And from then on they began to find new materials and applications.

During the last four decades, perovskite ceramics (formed by zirconium and lead titanate) have been used as piezoelectric material, especially in acoustic applications. Because of their characteristics they are suitable for it and have been used successfully for many other things. However, piezo ceramics present disadvantages such as low deformation, fragility and high mass density. Thus, they are not suitable for sectors such as aeronautics or electric-electronics. These limitations can be overcome in specific applications by replacing ceramic materials with polymeric piezoelectric materials.

Some piezoelectric polymers could be known from the 1920s, but not much attention was paid to them until the 1960s. Then, Fukada and his colleagues discovered that by exerting mechanical force on rounded polypeptide films and other polymers an electric charge was produced on their surfaces. Later, Kawai discovered in 1969 the piezoelectric capacity of vinyl polyfluoride (PVDF). This was a breakthrough, as the piezoelectric effect observed in PVDF was ten times higher than that observed in any other polymer.

Piezoelectric polymers are much more flexible than ceramics, do not break, are lighter and are much more adaptable. In addition, they have better properties for sensor function. Piezoelectric polymers are currently used in medical equipment, robotics, electronics and transducers, among others.

But the only piezoelectric polymer currently on the market is that vinyl polyfluoride of 1969 --and its copolymers -. It is a semi-crystalline polymer with very good piezoelectric properties as mentioned above, but does not support temperatures above 90ºC. From this temperature, it loses the piezoelectric property. Therefore, researchers are trying to synthesize new piezoelectric polymers capable of maintaining their properties at higher temperatures so that piezoelectric polymers have more applications.

Piezoelectricity at high temperatures

The Plastics and Composites Department of GAIKER-IK4 has been working in this field for several years. Research conducted in collaboration with the UPV Department of Physical Chemistry has led to the creation of new piezoelectric polymers. They have also applied for patents at the Spanish Patent and Trademark Office.

They have created amorphous piezoelectric polymers capable of withstanding temperatures higher than those of semi-crystalline polymers. After testing different materials, we finally opted for the use of polyimides, for its excellent thermal, mechanical and dielectric properties. In these molecules several dipolar groups have been introduced (-CN, -SO 2 -, -CF 3), modifying their number and position to model their physical properties and therefore their piezoelectric properties.

On the other hand, for these polyimides it has been considered that the value of the glass transition temperature is fundamental, since it determines at what temperature the piezoelectric properties are lost. Piezoelectric polyimides maintain a piezoelectric stability up to 150 °C and do not begin to degrade until exceeding temperatures above 400 °C. Therefore, piezoelectric polyimides may be appropriate to use polymers in previously unused conditions.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia