Oil transport: international debate

2003/06/01 Lasa Iglesias, Aitziber - STEAM Hezkuntza arloko arduraduna Iturria: Elhuyar aldizkaria

Oil, viscous substance, black, dirty, likin, lirding and this pollutant, unlike other ships, have specific technical characteristics.

As for their size, there are differences between the packages used in international oil transport, from a coastal boat to an ULCC (Ultra Large Crude Carrier).

In 1999, the total capacity of oil tankers worldwide amounted to 280 million tons. The transportable volume in a container increases with the length of the container, which is the cube of the length of the container. That is, although an ULCC is twice as long as a coastal boat (415 m versus 205 m), it can transport up to eight times more oil (400,000 tons versus 50,000 tons). There are other types of intermediate packaging: Aframax (245 m long and capacity of 80,000 tons), Suez-Max (285 m long and 160,000 tons capacity) and VLCC (350 m long and capacity of 300,000 tons).

Today, more than anything, the size of the vessels is limited by the size of ports and channels, such as the Suez-Max type, which initially had the maximum extent allowed by the Suez Canal.

These large dimensions and capacities make packaging very inertia. That's why it's hard to drive. For example, a giant cargo ship would take 3 km and 15 minutes to stay completely, while the turning diameter is about 2 km. The average speed of an oil tanker is 15 knots, that is, 28 km/h, which means that in one day it reaches 575 km. The boats that have been built in the latter can form between 25 and 30 knots (45-55 km/h). Boat propulsion machines began with steam engines, and although the diesel engine was a breakthrough, gas turbines are the most suitable machines today. The double helix has also been a very important discovery. However, subsequent improvements are costly.

But improvements in oil tankers have to go another line. The design of these gigantic ships is of great importance. The initial containers were made of wood; although the following ones were made of wood, they had a steel structure; then the containers were completely made of steel (at the beginning of the warships) and nowadays steel, aluminium and composites are raw materials. But what needs to be taken care of is the design of the structure. Since the 1950s, at the international congresses held, steps have been taken in the search for the less polluting system.

Oilpol 1954

In 1954 an international convention against oil pollution of the sea was held: OILPOL (1954). As was said at the time about the total consensus, oil pollution is mainly due to the usual cleaning work of the containers. In the 1950s the containers were washed with water inside and the water-oil mixture was poured into the sea. In view of this, OILPOL proposed adopting measures, stating that these cleaning work should be carried out at a minimum distance from the soil. This was the first step in cleaning.

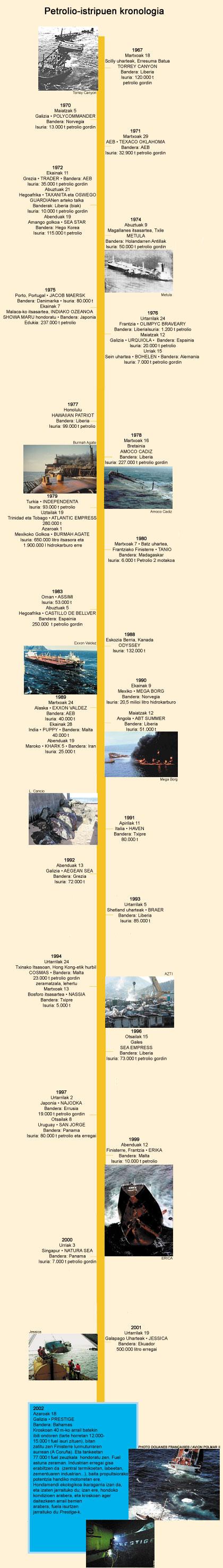

In 1967, oil tanker Torrey Canyon hit reefs near England. As a result of the collision, six deposits broke and many others were damaged, 120,000 tons of oil poured into the sea and, with the help of the force of the sea, the first black tide ever occurred reached the beaches of Cornwall in England, the island of Guernsey and Brittany. Many of the measures that were taken to solve the incident were worse than the problem itself, for example, many of the detergents that were launched sometimes to clean them (15,000 t) generated more pollution than the spill itself. However, this accident marked a turning point throughout history and saw the need to take action internationally. In addition, the weaknesses of the grant system were detected after such disasters. To discuss all this, the MARPOL Convention was organized in 1973.

The pollution caused by accidents is very spectacular, although it had to be recognized that the biggest challenge was to avoid contamination caused by conventional cleaning. For example, a new procedure was proposed: instead of directly pulling the oil water mixture at the time of cleaning, it had to be thrown into a special tank, and on the way to the new load the oil would go up and the water down. Only the underlying water had to be thrown into the load and the higher oil recycled. The order to follow this procedure came into force in 1978.

Marpol

The main conclusions of the MARPOL International Convention were, on the one hand, the request to governments of capacity to receive the mixtures generated in cleaning operations in ports and cargo areas and, on the other, the requirement that ballast deposits in new vessels of more than 70,000 tons of capacity be separated from the product to be transported. Let's see what this second measure is.

Giant tankers make very long journeys. They are stable structures with high weight while driving oil. However, if they had to travel back with simple oil tanks, the boat would be very weak and the trip would be dangerous. Therefore, they fill the tanks with sea water to carry them in the form of ballast and when they arrive at the port of origin they release the water. These deposits were the same ones that transported oil, which caused a huge pollution in the sea. And keep in mind that we are talking about a common procedure. Therefore, the separation of ballast deposits would mean a significant decrease in this pollution.

But this proposal was not well received by boat producing countries.

Time passed, but MARPOL did not have much follow-up. However, new accidents occurred. And in 1978 a new conference was organized, which was called MARPOL 1978. The main conclusions are two: firstly, the need to separate ballast deposits that were extended to the new containers of more than 20,000 tons of capacity, as well as the regulation of the ballast location in the container itself; secondly, a system of cleaning deposits by means of hot crude blasting in ships of more than 20,000 tons was proposed. Because oil is very viscous, hot crude jets could help empty the tank.

Although all these regulations were major barriers for shipbuilders, some countries pushed the deal, including the US.

A month after the closing of the conference there was the largest spill in France: The oil tanker Amoco Cádiz spilled 227,000 tons of crude oil.

MARPOL 1973/78 was ratified by many States in 1982 and entered into force in 1983.

The procedure for measures to be taken by the 1984 amendments in case of an accident with oil pollution was designed and entered into force in 1993.

The accident suffered by Exxon Valdez in 1989 also put a new turning point, that is, from that moment all oil tankers entering the United States ports must have double hull. As on previous occasions, the oil industry was not very willing to consider double-hull vessels as accidental, mainly due to the adaptation costs of existing vessels.

As of July 1993, the request for double-hull or equivalent vessels is in force for newly constructed vessels. However, on 1 January 2000 only 20% of the world's oil tankers were double-hull.

Erika

However, in 1998 the ship Erika sank. This accident attracted the next step of the accident chain. In fact, since then the Erika proposals were published. And the proposals go in the same line. To a large extent it is intended to ensure control and compliance with regulations. This is a commitment by the oil industry not to use old ships.

However, accidents occur... Why?

As for safety, if shipping is safer than 20 years ago, but in December 1998 Erika suffered an accident on the French coast and in November 2002 the Prestige has sunk, causing in both cases major catastrophes. What is the problem?

MARPOL agreements have influenced the reduction of oil pollution emitted by ships, although not all oil-producing nations have ratified MARPOL.

And that is one of the current problems. That is, you cannot control shipping worldwide and not all countries meet the standards equally. In fact, in some countries, a system called “open records” has been implemented that allows external oil companies to register. Therefore, being the most important key of the oil business the location of the cheapest oil tankers, the ships of many peoples receive a flag of convenience. The main reasons are related to lower licensing costs, tax evasion and lower security requirements. As a result, many European companies, such as Liberia, Panama, the Bahamas, Cyprus or Malta, take the flag of countries where the business is cheaper. And in the same line, the age of boats is not important either. Therefore, the older the boat, the cheaper it is. As a result, in 1999 the world average age of oil tankers was 18 years, and 41% were over 20 years old.

Following the Prestige disaster, the G8 Zortziko Taldea (Group of Eight) has proposed new measures. Above all, it is a question of asking the oil industry for an important part of the economic aid to the victims and of creating the rules for it. On the other hand, you want to completely remove the containers from a single helmet.

For more information on shipping oil, click here

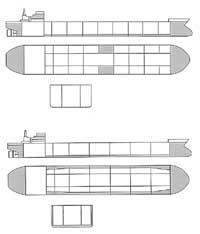

Double hull packages

Bottom: Double hull packaging design.

In 1992, after the disaster caused by the ship Exxon Valdez, the precariousness of double-hull vessels came into force, following MARPOL orders. Single-hull packages. The design of ships with a single hull is called Pre MARPOL design. In single-hull containers there is only one foil between oil and sea water. Suppose a collision produces some damage to the blade, then it is very easy to pour into the sea the cargo carried by the vessel, both oil and fuel or other product. A good way to avoid this risk would be to store this load using a second sheet (1.5-2 m from the outer hull). Packaging with this design is thus called double hull packaging.

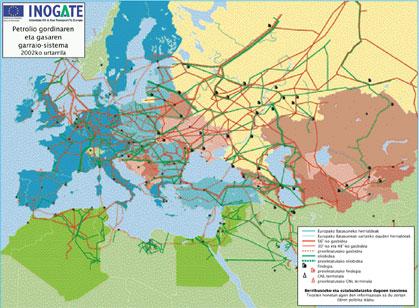

Pipelines, component of maritime transport

Although oil is mostly transported by sea, in many cases the extraction point is not near the coast or the port. One of the ways to bring crude oil to refineries or to transport products from refineries are pipelines.

XIX. Since oil extraction began in the 18th century, the first was built in the United States in 1865 and had a length of 14 and a half kilometers. Today, the pipelines have been highly developed and specialized and traverse very wide territories such as Siberia or Alaska (Alaska's main pipeline is 1,280 kilometers). In most cases they are used as the most economical alternative to other land transports, since oil is transported at very long distances and continuously.

The movement of oil through the pipes is made by pumps moved by electric motors or gas turbines. Crude oil and its derivatives can reach a speed of 5 to 13 kilometers per hour in the tube depending on its diameter and pressure, as well as the topography of the territory and the viscosity of the term.

In addition to oil and its derivatives, there are pipelines that transport natural gas, forming a very important network (see map above).

Pipelines can be sources of contamination. Despite the difficult explosion of oil, the rupture of the pipes can cause contamination of the surrounding lands and waters. It is therefore very important that pipeline maintenance is adequate. In the usual states of the Soviet Union, the problem of obsolete pipelines is quite serious, as they generate a lot of pollution and do not have enough money to renew them. One of the few solutions companies coming from abroad have is to invest in these countries.

Related information

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia