Cold Price

1991/07/01 Barrenetxea, Tere - Elhuyar Fundazioa Iturria: Elhuyar aldizkaria

One of the components of the insulation of refrigerators and freezers is chlorofluorocarbons. The controversy raised in recent years by the impact of these products on the ozone layer has left aside another of the worrying aspects of refrigerators, which is the high energy consumption of these appliances.

Refrigerator and energy consumption

Although the cost of operating the refrigerator seems very low among household expenses, it should be noted that there are many millions of refrigerators that are operating in the world. For example, in Britain there are only 30 million and 8% of the energy produced in those territories is consumed by these devices. The difference between the energy consumption of refrigerators and freezers sold can be very large, more than double between two models with similar performance.

Most large series refrigerators, freezers and refrigerators/freezers consume 1 to 3 kilowatts per model, size, power and construction characteristics.

The characteristics that can increase the energy consumption of large series appliances are:

- Fine insulation. A better use of space has brought with it a worse isolation.

- Defective door closure. They allow to escape the cold air of the sections.

- Low efficiency motors.

- Compressor of bad design. Instead of using the energy to compress the coolant fluid, it dissipates it into turbulence.

- Poor positioning of the engine and compressor. The heat produced by these can enter the interior of the chamber.

- Too small heat exchangers (condensers and vaporizers). They need more energy than those of adequate size to expel heat from the camera.

All these factors increase energy consumption. The design of refrigerators for decades was more suitable from the point of view of energy consumption. However, the energy shortage between 1955 and 1973 caused the abandonment of these models. They had very thick insulation and needed more space than the new models.

Low-consumption prototypes

Some households have already begun to market, although only at the prototype level, higher performance models. The most efficient refrigerator manufactured in Europe is the one that launched the Danish firm Gram in 1988. This refrigerator has a 65mm insulation, a good door closure, a small and efficient motor/compressor and a larger than normal evaporator and condenser. The Norgard fridge, which has this name, has an annual consumption of 0.4 kWh/l.

A small Californian factory manufactures refrigerators with consumption between 0.2 and 0.3 kWh/l since 1984. It sells every year between 100 and 200 units of this type. These refrigerators are bought, so to speak, for houses far from civilization. That is, away from the electricity grid, for homes powered by solar energy cells. To achieve this level of performance, the details have been improved: thickness between 80 and 100 mm, hermetic seals, coolant with the most suitable characteristics for the temperature and pressure to which you will work, etc.

In the municipalities of the North, being the lowest average annual temperatures (between 8 and 10 ° C), cold chambers can be built adapted to these situations so that consumption continues to decrease. We have found two special cases. The first would be a refrigerator with the condenser outside the house and the second, with the natural refrigerant system, circulating the new melted snow by a pump. But in these relatively special cases, let us return to the world of mass-produced refrigerators.

Thicker refrigerators

According to many European manufacturers, the inability to use CFCs that damage the ozone layer in refrigerators will increase the energy consumption of these appliances by 10%. Let us see the reason for this.

80% or 90% of the CFCs used in refrigerators correspond to insulation. Other products currently known for use in insulation have greater thermal conductivity. Consequently, and as long as no further change occurs, these future potential refrigerators will have a higher energy consumption. To maintain the insulation level, the insulation thickness should be increased from 15% to 25%. This solution is totally unacceptable for European manufacturers for various reasons, so for now some have chosen to use other less harmful CFCs.

The use of polyurethane treated with CFCs for insulation had significant advantages over the previous system. The thickness of 50 mm of mineral fiber that was previously used allowed to reach the same level of insulation offered by 30 mm thick polyurethane foam. So did the European manufacturers. The Americans, on the other hand, did not tune the insulation, but used the advantage of polyurethane to make higher-performance refrigerators without thinning walls.

The thickening of the insulation would mean leaving aside the width of 600 mm that has now become standard kitchen design, which would have several consequences:

- Since designers work with standard measurements, it is very difficult to introduce such a variable.

- The manufacturer would need new injection molds used for manufacturing, which would increase costs.

- The price of the final product put on sale would increase, although considering that they have a lower energy consumption, this would mean a recoverable investment for the buyer over the years.

Consumer orientation

For consumers, however, the advantage of a well-insulated refrigerator is that the temperature distribution is more uniform and therefore food is better preserved because there are no unrefrigerated corners. In case of power failure, food lasts much longer. And the last advantage is that thick doors of good gasket prevent the entry of heat and humid air into the interior of the chamber, so the food accumulates more slowly in the freezer and you have to disagree less times.

We have seen the advantages of high-performance refrigerators. If the consumer wants to take advantage of these advantages, the first thing they need is to know the characteristics of the refrigerator or freezer. The reliable electricity consumption of each appliance should be clearly announced along with other features. Only this could provide the necessary information for the consumer to decide the purchase.

Each State establishes minimum standards for manufacturers for the performance of each device and compliance audits are performed on the devices it markets. The order to predict electrical consumption per device, as well as how to advertise it, varies from state to state. In the French state, for example, the seller is obliged to explain in each device, together with other characteristics, energy consumption. In the Spanish state the seller does not have that obligation, so only a few are those who express themselves.

According to the new minimum standards established in the United States, 90% of existing refrigerators and freezers on the market in 1987 would be outlawed. With this policy, consumers will save $28 trillion in the United States by 2000 and the construction of 25 energy stations will be avoided.

In Britain, the organization Friends of the Earth estimates that if all the refrigerators available on the market were like the best, it would have to produce 600 megawatts less. And this would be a small step, according to this organization, because the devices on the market in Britain are very poor performance. Compared to the best existing in the European market, they claim that the demand for electricity would be reduced by 1,500 megawatts.

But going further, another dark point appears: When requirements for Western standards are hardened, appliances that cannot be sold in them are sold to other locations. Most refrigerators sold in China are manufactured in Japan and the United States, but do not meet the minimum required to sell in the United States.

In recent years great efforts have been made to achieve more profitable power generation stations in many villages. This effort, logically, should be accompanied by the promotion of research and manufacturing in high-energy applications.

Sweden, for example, wants to avoid the need for nuclear power plants that generate half the energy used in it over the next two decades. And they don't want to suffer other discomfort, that is, they don't want to raise the levels of carbon dioxide emissions, build more reservoirs to feed hydroelectric plants and finally they don't want life to be reduced. The bet is the use of high-energy technology.

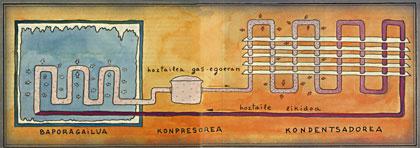

REFRIGERATORThe refrigerator is a heat moving machine. By removing the inner heat it manages to lower the temperature. This expelled heat is heated and the outside air is lost. Refrigerators work by evaporation. Liquids evaporate or evaporate lose heat and cool. Vaporizer The coolant comes out at low pressure from the expansion valve to the tube and evaporates by cooling. As the vaporizer is inside the refrigerator, it receives local heat when the refrigerant evaporates. Compressor Electric refrigerators incorporate a compressor that circulates the refrigerant. The compressor pumps the vaporizer coolant to the condenser. Condenser The coolant comes out of the compressor at high pressure. As it passes through the condenser this vapor returns to liquefied. While this happens, the steam releases heat, so the condenser heats up. The condenser is located at the back of the refrigerator and this heat is expelled into the surrounding air. |

In search of resolution: Case of FAGORJosé Miguel Gorospe, head of the Department of Refrigeration Engineering of the cooperative FAGOR Appliances, visited us to ask us about FAGOR plans to improve the energy performance of its refrigerators. It has chosen to reduce the harmful components of polyurethane used for thermal insulation. Mr. Gorospe also gave us concrete data: the topic used today to lift polyurethane is Freon 11. Now this F11 represents 20% of the total mix. Other mixtures have been tested to reduce the amount of CFCs and only F11 has been used to 8%. The next step would be to replace F11 with F123. It is still being studied, but it seems that its impact is not so negative and therefore would be a major improvement. When asked about the possibility of making thicker walls, the answer has been totally negative. They say that it would have no future in the market and that in addition to that, the whole manufacturing process would be turned upside down: polyurethane injection molds, trays and other accessories, etc. They are prepared for standard measurements and the change of these characteristics does not pass through the head. |

From users

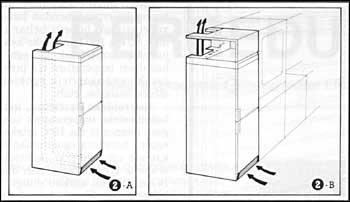

The responsible consumer has purchased a refrigerator with good energy performance. He does not want electric power to be wasted from his ingenuity. But not everything ends there. Now take care of the location of the refrigerator. The main points to consider are: the location must be DRY and WELL VENTILATED and AWAY FROM HEAT SOURCES.

It is very important that air traffic is adequate. To do this you have to leave the front, the back and the top free, as seen in the image. In the event that all appliances are installed during the kitchen installation, the release of these spaces must be allowed. Please note that the radiator located at the back of the refrigerator is a heat exchanger and that to fulfill its function it is necessary to renew the air. Otherwise, it is useless to buy a low energy device.

Secondly, it is necessary not to be close to heat sources. As far as possible, therefore, from the windows where the kitchen and the sun impact.

Once well positioned, it would be well used. To do this, keep in mind: do not introduce hot foods, leave spaces between the packages to circulate the air, check that the doors are well closed and of course do not open doors or keep them open.

The maximum standards established by UNE 86-002-79 for four-star refrigerators for marketing in Spain are: Maximumconsumption of the refrigerator in dm 3 tankWh 24 h tankWh maximum annual consumption and per liter*120 150 200 250 300 3501,692 1,812 2,070 2,358 2,655 2,9525,07 4,35 3,73 3,39 3,04 * The maximum |

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia