Towards automated battery research

2020/11/24 Lakuntza Irigoien, Oier - CIC Energiguneko ikertzailea Iturria: Elhuyar aldizkaria

There are many people who work in the research of batteries: in the theoretical work, in the synthesis of materials, in the characterization… It is a great job and the results often arrive at a speed lower than desired. Artificial intelligence could accelerate this process a lot to get new battery components in automated labs!

As the development of mobile devices advances, the need for batteries to store the energy that devices need will increase considerably. In short, electric vehicles, the use of renewable energies, drones and sanitary implants are in constant expansion, and to respond to this development Europe must have the capacity to produce batteries that store a total energy of between 200 GWh and 1 TWh.

As is known, lithium-ion batteries (VOL) are the most commonly used batteries today. However, these batteries are already reaching their maximum energy density, which implies the investigation of new systems. However, this is usually a laborious job. In fact, the periodic table offers a very wide composition field, and once selected one of them, it is essential to synthesize it and analyze its properties. In essence, this is the limiting step in the search for new materials, since we see the validity of all the work done previously. If no satisfactory results are obtained, it is necessary to restart the process from the beginning.

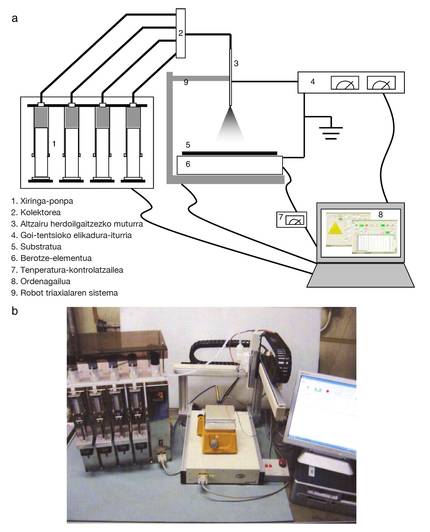

A research project led by researchers at CIC EnergiGUNE, Javier Carrasco and Marine Reinaud, seeks to create a material development platform that streamlines and embraces this process. This platform will synthesize and characterize autonomously selected structures from basic atomic calculations, automated learning and artificial intelligence (AI), which will accelerate and strongly encompass the process of obtaining materials.

Usual procedure and history of automation

The search for new materials has always been a process of experimentation based on the intuition of the researchers. This process, long and costly, has given good results in research on catalysis, polymers and electrolytes.

This procedure is especially effective when combined with highly accurate theoretical methods. In the research of components for batteries, this procedure has paid off to validate electrolyte additives and analyze the preparation conditions of the compound LiNi1/3Mn1/3Co1/3O2 for lithium batteries.

However, as the number of chemical variables increases, this systematic search is not possible and at present it is a question of analyzing the variables selectively and of reducing the experiments to be carried out. Basically, the conventional search process is managed as an optimization process, and a data guidance algorithm replaces the chemical intuition of researchers.

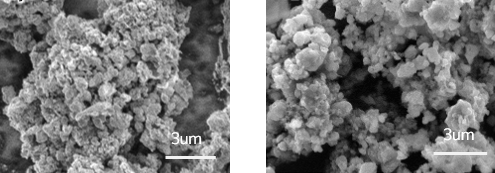

When there are few experimental conditions that can change at a time, the experiments that are carried out by themselves are viable. For example, the study of the conditions of synthesis of nanoparticles or the most adequate composition of solvents has been carried out through autonomous experiments. However, as the number of variables to take into account increases (experimental conditions, composition, etc.) Other methods are necessary.

Therefore, the advances that are being made in the fields of machine learning and artificial intelligence are of great help to solve this problem. For example, machine learning algorithms can search for relationships between variables, which can serve to predict the results of experiments performed under certain conditions. Thus, automated experiments guided by artificial intelligence are also spreading in the material sciences. Proof of this are the platforms that modify their optical and electrical properties autonomously modifying the composition or the conditions of creation of the fine ones.

Also available are the techniques of obtaining new materials for batteries. The problem is that the synthesis protocols and characterization are not regulated. This is because, being often unknown results in what specific conditions have been obtained, these results cannot be interpreted with precision, which makes them not universally applicable.

Project in progress

This project by CIC EnergiGUNE has two main objectives: on the one hand, the correct use of artificial intelligence algorithms for experimental planning and, on the other, the control of automated synthesis of materials through the results that are being obtained.

The platform for the development of materials, based on the calculations made through the basic principles and the results of previous experiments, will announce the results of the experiments that would be carried out according to some control parameters. If appropriate, the experiment will be carried out autonomously, and depending on the results obtained, the synthesis procedure will be tuned, seeking relationships between the established control parameters and the results obtained. On the contrary, if the results announced are not so desirable, it will study other synthesis alternatives.

As a starting point, the material development platform will work on two systems:

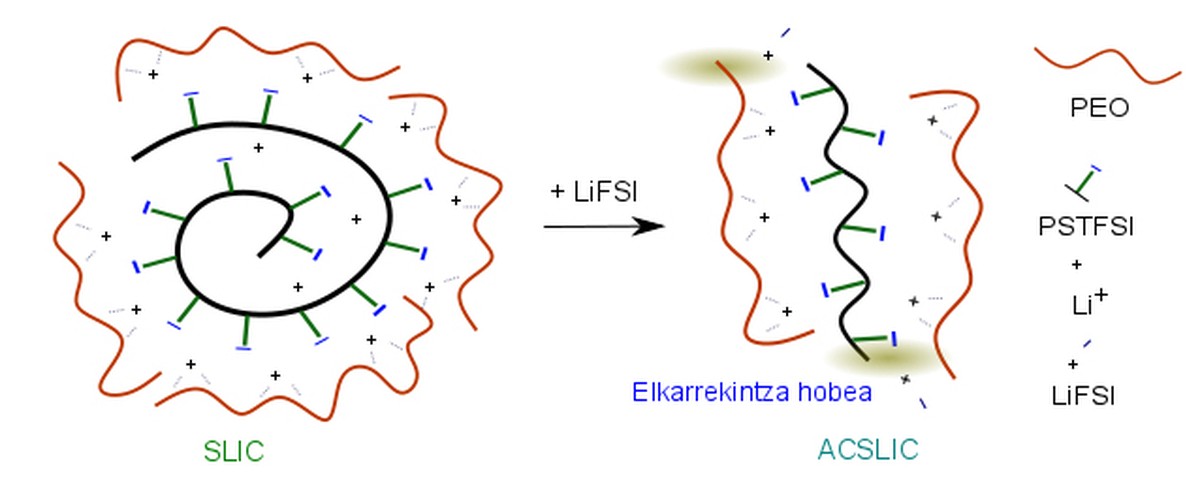

- Li-Ni-Mn-Mg-Al-O: to reduce the amount of cobalt (Co) used in the electrodes of most current commercial VOLS, this element has been considered to be replaced by magnesium (Mg) or aluminum (Al).

- NaMPO4 (M=Mn, Faith, Ni, Co): Being LiFePO4 the reference cathode of PAHO, it is important to properly investigate this system, since this would be the parallel cathode in sodium ion batteries.

Once these two systems have been investigated, the material development platform and acquired knowledge will be used to investigate other systems of interest for new batteries.

Therefore, it can be affirmed that artificial intelligence has reached the investigation of new batteries. In essence, after having researched much about artificial intelligence, it is now artificial intelligence itself that begins to investigate what man was investigating.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia