Fake diamonds

The synthetic diamond is made commercially by combining high pressures, chemical vapor precipitation and shock-wave processes. But being a very expensive method, it is rarely done. Although other methods have recently appeared, such as plasma activation, exotic precursors or explosive mixtures, the results have not been very satisfactory, as they are limited to small volumes or thin layers.

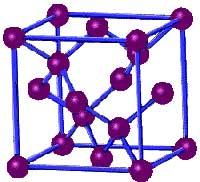

However, the scrub diamond obtained by the chemical method invented by researchers at Drexel University of Philadelphia and the University of Illinois presents hopeful mechanical characteristics. To do this they extract silicon from silicon carbide, combining gas with chlorine and temperatures of 1.000 C. This temperature is not very high and high pressures are not used. Thanks to the hydrogen present in the gas mixture, silicon carbide becomes allotropic carbon with diamond structure. The average crystal size ranges from 5-10 nm. The linear kinetic reaction changes to any depth, so the silicon carbide sample becomes a complete material with diamond structure. In addition, the new material obtained is porous and has the capacity to drive electricity.

Nanocrystalline layers of carbon with diamond structure can be widely used in the industry, for example for making very hard covers for brake shoes.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian