How can we know if the welding is well done?

2002/05/14 Elhuyar Zientzia

The traditional system of joining two metal parts is welding, but these welded areas are the most important, especially if the joints are badly made.

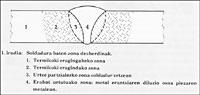

Welding is done by heating, melting and joining the terminals of two plates, or melting another similar metal and using it as a conjunction.

But this board should be as homogeneous as possible. In fact, if bubbles or holes appear, before any force the piece breaks.

These weaknesses are observed by advanced technology, as it is evident that the part cannot be broken to check whether the weld cord is well constructed.

Techniques used to monitor weld volumetry include x-ray, gamma ray and ultrasound.

Due to the ability to pass through materials by X-rays or gamma rays, X-rays of such rays are used for the inspection of welds, smelters, forges and materials in general. In fact, once the weld cord is crossed, the rays are collected on a photographic plate, and if the image is not homogeneous, it is a signal that the welding itself is not homogeneous.

Ultrasonic inspection also lets you know the location, size and orientation of the fracture. On the other hand, this technique has the advantage of reaching a single side of the piece, since the sound is emitted and received on the same side.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia