La Mancha tunnel about to end

1991/07/01 Otaolaurretxi, Jon Iturria: Elhuyar aldizkaria

The journal ELHUYAR has already published articles on the La Mancha tunnel (see 11.2 167, 1985). Unit 75 of 1986 p. Page 29 of 1989. and 1995, number 43, 5th p. ), but as it is expected that this summer the triple tunnel will be fully excavated, we consider it interesting to give more detail to this giant work.

When the Manche Tunnel Railway starts operating in June 1993, an excursion from France to Great Britain can be made and vice versa “from the ground”. The High Speed Train, in its special cars, will transport passengers, vehicles and cargo in about three hours from Paris to London, reaching a speed of 160 km/h.

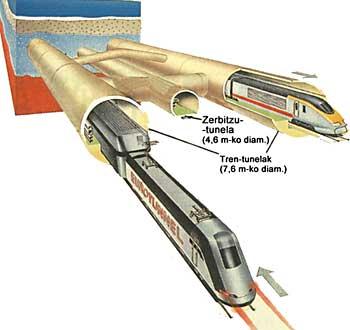

The railway under the Channel of La Mancha consists of three parallel tunnels, with a length of 7.6 meters in diameter on the two margins (by which the trains will run) and 4.6 meters in diameter in the center (for maintenance, safety, etc. ). It should be noted that the small central tunnel has connections with the other two sides every 375 meters.

In case of failure, repairs would be made from the small central tunnel, and in case of accident or fire, travelers must remain in the same until the arrival of assistance. The ventilation network will also be governed from this central tunnel.

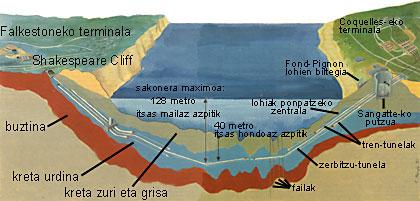

Excavations began in 1987 at Shakespeare Cliff. In the French part, in Sangatte (10 kilometers from Calais) began to drill after a large well of 57 meters in diameter and 65 meters deep. From this point, three gigantic drilling machines began to open up other parallel galleries. The other two machines have dug the three roads from Sangatt to Beussingue, next to Coquelles. One of these last two machines has built the small central tunnel and the other the railway tunnel to Sangatte-Beussingua. He then turned around and returned from Beussingu to Sangate opening the third parallel tunnel.

In total, French and British have simultaneously had eleven giant machines in drilling. French machines were designed to work on water. In fact, in the underground blue crete of La Mancha there are many faults or cracks on the side of France and the risk of sea water reaching it.

In the Sangatt well, drilling sludge is pumped to the decanting area in nearby Fond-Pignon.

On 1 December the central tunnel was completely open when British and French found themselves 50 meters below the sea floor. Previously, the British drilling machine Robin abandoned its path and was buried in the place. Subsequently, the French machine Brigitte drilled the last meters to join both sides.

Tunnel drilling moles

The opening of the galleries has been made with huge machines. They have used 150 kilometers of tunnels up to 11 machines, with their most beautiful names: Virginie, Catherine, Séverine, Brigitte, etc. Each of them has cut an average of 500 meters a month, in hours of night and day, as well as in parties and weeks.

The weight of these machines ranges from 1,000 to 2,500 tons. They are like a long worm, with a punching cylinder at the tip. In the tunnels of the edges to which the trains are directed, the drilling cylinder of the machine has a length of 12 meters and a diameter of 8.80 meters. Their long bodies, 250 meters.

In the long body of the machine or mole are all the controls and mechanisms necessary to govern the drilling: conveyors for waste extraction, concrete slab, greasing and ventilation systems and power supply.

Each of the three machines that have been punctured from the French area has been prepared to become a scuba dive abruptly. They could withstand a pressure of 11 kg/cm 2 or a hydraulic force of 6,000 tons if marine waters entered through cracks. British machines have not had the need to design them this way, since, unlike the French area, the blue crete of the area is homogeneous and waterproof.

The machines in the area of France, finding water, have turned the drilling head of the machine into an airtight, completely separating the water from the body of the machine. Thus, the drilling speed has been lower, but the rear and material have remained safe.

A machine, Pascaline, after drilling the tunnel of passage of the train from Sangatt to Coquelles, turned on December 18 last year and opened the same gallery from Coquelles to Sangate. The machine head weighed 800 tons and there were no cranes that rotated in full. However, they didn't want her to have fun and put some air mattresses under her to turn the swing. 32 mattresses were inflated up to a pressure of 3.5 kg/cm 2 using six compressors. The total compressors were 140,000 litres/minute. The maneuver was complicated in itself, but it was easily carried out on the concrete platform coated with epoxy resin.

Pascaline

Earlier, however, Virginie had drilled the central service tunnel from Sangat to Coquelles. It took ten months to build a 3.2 kilometer tunnel, but finally, on April 27 last year, its thorny end could be seen in the outside light.

Concrete rings

In the 150 kilometres of tunnels under the English Channel 120,000 concrete rings have been placed. The holes have been lined outwardly with large reinforced concrete rings between 32 and 40 centimeters thick. Each ring consists of six candles and the weight of each candle ranges from 3.6 to 8 tons. In total, 720,000 dovelas have been placed in the tunnels.

The Sangatte plant has built 221,000 sheaves, using 490,000 m 3 concrete and 35,000 tons of steel. (Only in steel three times more than in the Eiffel Tower.

The sheave armor is a kind of automatically welded cage, which was inserted into a mold and filled with concrete. Five uninterrupted manufacturing lines have been manufactured at Sangatt.

The dovela was put in its mold to an oven so that it dries faster and hardens. Thanks to this system, the molds were removed in 8 hours. Once the mold was removed, the surfaces were manually reviewed for 28 days to gain hardness and compressive strength. The concrete resistance was 55 MPa, 20% higher than that of conventional concrete in construction.

To identify each piece they were marked with unremoved ink and subsequently neoprene joints were placed. Especially on the perimeter, so that then not enter water in the worst conditions inside the tunnel. In fact, the entry of water from an underground fault should maintain a water pressure of one hundred meters high in the sea.

Depending on whether the tunnel is a train or a service or its radius of curvature, a series of 54 different types have been placed. The type of candles that are selected for each location indicated from the machine control panel. The tunnel operator sent the request to the computerized center of Sangatt, from where automatically five automatic cranes collected six dovelas from the park correctly and placed in the tunnel wagons. The 40 ton load was finally placed on the walls by a few drilling machine arms forming a protective ring.

Adjusting the six pieces to the millimeter, it was tied in place and the mortar was injected into pressure between the wall and the ring. Then the machine drilled enough to place a ring on the rock and so they have gone to the end.

A sophisticated autonomous factory was installed for the manufacture of the dovelas. It has manufactured 400 or 450 units daily, one every three minutes. On a platform of 26,000 square meters they have remained 28 days outside to reach their proper hardness and resistance.

What to do with mud and debris?

For drilling and extraction of sponged rubble, each machine had a material of 1,300 tons and consumed 8,000 kWxh. The mud extracted from the tunnel has been stacked in the place called Fond-Pignon, located a hundred meters from the work. For this purpose a tube of 13 kilometers in length and 25 centimeters in diameter has been used. The waste has been deposited on a hillside supported by a dam 28 meters high on the edge. A filling of 1,100,000 m3 was performed, after drying of lime materials.

Unlike conventional dams, Fond-Pignon is not completely waterproof. Sludge has a relatively large thickness of sand drainage. In the surroundings there are no remnants of granulometry needed and had to be brought from the sea of Belgium. Once drained, the water from the sludge is taken back to the tunnel so that the sponged debris are wet there and can go out more easily to the outside. Once the works are finished, three million cubic meters of mud will be stacked in the Fond-Pignon dam and after its decantation work will be undertaken landscape integration.

Fond-Pignon is a huge tunnel waste warehouse. With the three drilling machines at the same time, it was estimated that three meters per hour were advanced, which meant that 625 m 3 /h of rubble were obtained. The treatment center for these rubble has been located in the vertical well of Sangatt at a depth of 50 meters. There the rubble has been wet and diluted (up to 50% approximately) to be able to handle them comfortably with pumps.

Although the most advanced technology has been used to drill tunnels, outdoor work has not been slow. An area of 700 hectares has been established in the Coquelles terminal, three times that of Folkeston. It is one of the most important works in the world in the field of civil engineering and hundreds of hiding places, trucks, bulldozer, etc. have lifted and displaced 10 million cubic meters of land and rubble.

Train design

Some travelers feel claustrophobia because of the subway. Therefore, the line train designers who intend to open on 15 June 1993 have taken into account many details so that ten thousand travelers travel comfortably every day.

Under the sea of La Mancha three types of wagons will circulate: Goods, Cars and Passengers and High Speed Train. It is estimated that in total 400 trains will circulate daily in the two tunnels during the peak traffic.

Passenger cars, like aircraft, will be totally pressurized and doors or windows will not be opened when they go in tunnel. Vehicles in special cars and travelers

It is estimated that half, without cars, will travel the sea that separates Britain from the continent. The trip from London to Paris will last just over three hours and only twenty of them in a tunnel.

In those twenty minutes underground, however, there is a risk that some traveler will be frightened and distress. Therefore, the psychological impact of the tunnel has not left aside the expert Roger Tallon who has designed the cars of the High Speed Train of La Mancha.

As for claustrophobia, it is the same to walk in the Manche tunnel as in the city subway. The metro takes a twenty minute trip to any city. However, according to Roger Tallon, something is associated with the anguish that occurs on the plane. It seems that there are people who feel that the sky is basically for the birds and the subsoil only for the savers and that a penalty will come for breaking that norm.

For all this, cars will be pressurized and air conditioning will be provided. They will be isolated outwardly, but also face the physical signs of the train's entrance to the tunnel. First, when the light level is reduced, the lighting will be reinforced. In addition to ceiling lamps, a light strip will be placed on each window. It will not be noticed if the light comes from outside or inside. These luminaires on the windows, even when the train is outside the tunnel, will go on to prevent people from moving into the tunnel.

The colors to be used inside the car have also been very important. Temperate tones, grained grey and solar color have been selected. Green is an appropriate color for the Germans, but the British do not accept it so well and do not forget that two-thirds of the travelers will be British.

The train will be exterior white and dark blue. The muzzle, however, will be yellow because British safety standards force it; it is ideal to see the locomotive in the fog of the island.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia