La Mancha tunnel advances

1989/11/01 Aizpurua Sarasola, Joxerra Iturria: Elhuyar aldizkaria

The tunnel being opened under the English Channel is scheduled to end on 15 June 1993. More than two hundred years have passed since the first project was carried out, but this time the works are very advanced to leave them pure.

The implementation of this submarine communication medium will allow to transport 30 million passages and 15 million tons of cargo between the United Kingdom and the Continent; approximately 40% of the current traffic.

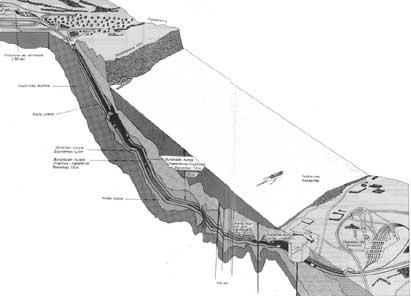

The Mancha tunnel consists of three parallel tunnels. Two of them have a diameter of 7.6 m and trains will circulate. Between these two tunnels there will be a 4.8 m diameter service tunnel. From the service tunnel, maintenance and ventilation will be carried out with connections to other tunnels at a height of 375 m. Most of the tunnel will be excavated by the British, which means a total of 92.4 km and the rest, 57.6 km French.

The reason is the geology of the earth. While the British pierce the crete layer in waterproof blue, the French must also pierce the white and grey crete layer, which is porous and full of cracks. Therefore, the sea water reaches until it is being drilled. Since the water pressure in some areas to be drilled is 11 atmospheres, special drilling conditions are required. Therefore, while on the one hand the drilling speed is 4.4 m/h, on the other it is 2/3 m/h.

The construction will be completed at 40 m below the seabed, that is, at an average depth of 100 m above sea level. The length of the three tunnels is 50 km, of which 37 km are submarines. The access points to the submarine train will be the British cities of Folkestone and Coquelles de France.

The replacement of the road by the railroad is due to economic safety reasons, that is, absence of traffic collapse, no pollution and low risk of accidents.

When the service starts, it will be operational 24 hours a day. The maximum speed of the trains will be 160 km/h and every hour will be able to circulate 20 trains in each direction. As the traffic of both people and goods demands it, you can travel 30 trains every hour. Trains will be driven automatically and between terminals “only”. The trains will consist of three types: on the one hand, two-storey wagons for the transport of cars and motorcycles, on the other hand, single-storey cars, trailers and vans and, finally, special cars, trucks and large loads. Each train will be able to transport 200 vehicles and will have a length of 795 m.

The crossing of the unilateral A26 motorway to the M20 motorway on the other side will take an hour and a quarter (the passage of the tunnel will take 30 minutes, the rest will be for cargo and passport formalities). Today it takes almost three hours to pass from one side to the other by boat and travel with almost two hovercraft. In addition, despite bad weather there will be no risk of service cut. There will also be differences in the price of the trip, as it will be 20% cheaper to go by train.

However, so far we have talked about the three tunnels, which are only part of all the work. In addition, terminals, Shakespeare Cliff platform, Sangatte moat and dovelas workshops will be built. In addition, 8 million cubic meters of waste land must be released.

Drilling machines are great engineering works. The machines used to drill the main tunnels have a diameter of 8.72 m, a length of 13 m and a weight of 1.200 t. The service tunnels, on the other hand, have a diameter of 5.74 m, a length of 11 m and a weight of 470 tons. From France five machines and six from the other side work. The drilling machines carry a wheel with tungsten carbide teeth and stones in front of them and are also able to remove residue and place dovelas. Neoprene joints are placed between the hinges forming rings.

This ensures the compactness and impermeability of the system. A total of 720,000 candles will be located. This requires 2.2 million cubic meters of concrete and 220,000 tons of steel. Dovelas are manufactured in Sangatte and the Tamise estuary, with a daily frequency of 500. Behind the machine runs a 250 m technical train in charge of ventilation, power supply, etc.

Not all drilling machines work the same. It has been said before that when drilling on the side of France they suffer strong pressures. Therefore, we have to work “closed”. In this case the drill works as a diver, formed by the last supported blades.

The other problem to overcome is getting the tunnels being drilled to have the same direction. Sophisticated laser systems are used for this purpose. This system also controls the smallest deviations, so holes on both sides are expected to be at the right point. The first intersection will take place in late 1990 and in service tunnel.

To access the tunnel from Paris, London or Brussels fast speed trains will be installed. Thus, it does not take more than three hours to travel from London to Paris, which today is needed to go by plane.

Although in 1987 it was estimated that the cost of drilling would amount to 7.680 million dollars, it is currently estimated that 11.2 billion dollars will be needed, representing a 50% increase over expected. Therefore, the Anglo-French consortium “Eurotunnel”, responsible for the construction, has announced that if banks do not invest the necessary money, in December they could be in danger of suspension of the works. However, as discussed at the beginning of this article, there seems to be no lack of money for this gigantic work to collapse.

In Sangatte, near Calais, a hole of 55 m in diameter and 65 m high was made. From the bottom of this hole began drilling towards the island. It consists of four bridge cranes, one of 430 t, two of 60 t and another of 30 t. This hole is a logistics center of works, from which 3.5 million cubic meters of wastewater will be channeled out of the drilling. Once the works are finished, the gap will be used to control the ventilation system. The construction of this gap has been carried out in two phases. On the one hand, to stop the influence of the groundwater layers it has been necessary to build an elliptical concrete ring. On the other hand, bentonite has been injected to support the lateral lands. Waste land from the excavation of the tunnels is taken to an underground chamber. Once ground, they become liquid substances that are poured by a pump to a dam one kilometer. The 4.5 million cubic meters of land that will come out in the UK will go to the expansion of the platform of Shakespeare Cliff. |

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia