Electrical and electronic waste

2002/06/01 Orobengoa, Olatz - Elhuyar Zientziaren Komunikazioa Iturria: Elhuyar aldizkaria

To date, 90% of all appliances have been deposited in landfill without any prior treatment, but lately the accumulation of these waste is becoming a serious problem.

According to a report issued by the European Union, six million tons of electrical and electronic waste (UK) were generated throughout Europe in 1998 (4% of total urban waste). This report forecasts that the annual volume of these waste will increase from 3% to 5%. This means that EHEs grow at an average speed of three times as much as urban waste.

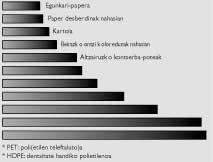

Electrical and electronic devices are much harder to recycle than glass or paper. Each device consists of circuits, cables, plastics, mercury switches, cathodic ray tubes, liquid crystal displays, accumulators, lighting devices, capacitors, resistances, etc. In addition, each of these components contains environmentally harmful materials, including heavy metals (mercury, lead, cadmium and chromium), halogenated substances (such as CFCs or polychlorinated biphenyls), PVC, brominated fire protection materials, asbestos and arsenic.

As already indicated, these waste and materials have been deposited in landfills without any treatment, with the consequent risk of contamination. High concentrations of heavy metals and halogenated substances measured in landfills are considered to be a direct consequence of the accumulation of HEE. In addition, the presence of substances in different types of substances, when burning waste, results in numerous chemical reactions, with a high risk of emissions to the atmosphere of molecules such as dioxins. The accumulation of heavy metals and chemicals instead of burning in controlled landfills poses a risk of leaching, i.e., dissolution in rainwater and filtration to soils near the landfill.

For all this, a couple of years ago the European Union launched a draft directive that will regulate HEE. This aims to limit the amount of hazardous materials used in the production of electrical and electronic devices and encourage the recycling of HEE already accumulated. The Directive states that 70% to 90% of EHEs should be recycled across Europe by the end of 2006, and heavy metals and brominated fire protection materials will be replaced by other less harmful materials from 1 January 2008.

History of recycling

The case of computers is quite significant. Since 25 years ago we started using these tools, growth has been spectacular. But the initial computers were big gadgets the size of a closet. For each of the devices in which a lot of materials were needed and their deterioration was profitable for the producing company the recycling of heavy metals present in it. Over time, however, computers have become smaller and less and less material is being used – and different types of materials have multiplied. For this reason, recycling of heavy metals and other materials is not currently profitable for production companies. The directive launched by the European Union proposes that producers assume the recycling costs of the HEE, so that in the design of the new appliances the recycling of materials is taken into account and the process is facilitated as much as possible.

Numerous companies in the Autonomous Community of the Basque Country have begun to advance this year. An example of this is the ‘Recifrigo’ project, developed by Fagor’s appliances department, in collaboration with INASMET, which analyses the degree of recyclability of refrigerators.

But how can these tools be recycled?

There is nothing more to see how many electrical and electronic devices exist in the market to understand the complexity of recycling them.

First, we have to classify each of the devices that have joined together and differentiate their components: plastic housings, cathode ray tubes, cables, etc. Then each component will make a different path. Reusable components will be sent to producers. Recyclable materials (plastics, heavy metals, glass and others) will be separated manually as far as possible. Non-recyclable fractions will be sent to burned or controlled landfills.

The biggest problems arise when characterizing the components with a large mixture of materials. To date it has been done manually, but handling highly polluting materials has a great impact on the health of workers. In addition, smaller components are increasingly used in appliances and when recycling the need for specialized machines is greater. In recent years numerous machines and methods of mechanical separation of these materials are appearing.

And what is the Autonomous Community of the Basque Country? In view of the good results obtained in the pilot experience held in Bilbao in 1994, from 1997 the Garbigunes were extended to the entire community. In them the HEE began to add up and the accumulated amount has been growing steadily. In 2000, for example, 710,707 kilos of HEE were collected. Currently, 77.73% of the collected is recycled (glass, iron and cables), while 0.3% of toxic waste is sent to authorized managers and plastics are not recycled because there are currently no markets for recycled plastics. Therefore, 21.97% of EHEs go to controlled landfills. The aim of the directive published by the European Union is to recycle 4 kilos of HEE per inhabitant and year. Currently only 2.4 kilos are recycled, so there is a long way to go. |

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia