Shale gas, the future?

2012/02/01 Irazabalbeitia, Inaki - kimikaria eta zientzia-dibulgatzaileaElhuyar Fundazioa Iturria: Elhuyar aldizkaria

For years the soil of Euskal Herria and surrounding territories are being excavated in search of natural gas. In the CAPV, the EVE Ente Vasco de la Energía has promoted this type of work. Despite the search for natural gas, the surveys are not for the search of conventional gas deposits, but for the collation of adsorbed gas in porous stones. Being adsorbed in schists, it is called shale gas, although it is a mixture of gaseous hydrocarbons composed mainly of methane, as well as natural gas.

In the Basque energy mix, natural gas has a 40% stake and is bought abroad. Patxi Lopez, on his visit to the US in October 2011, visited the Barnett gas area of Texas and announced that in the Alava Plain there is enough gas to ensure gas consumption in the CAPV for 60 years.

As indicated above, the main component of natural gas is methane (80-99% in volume), in addition to ethane, propane and butane. It also contains nitrogen, carbon dioxide and hydrogen sulfide. The natural gas we usually use is buried in waterproof bags, often along with oil. When drilling the well, the bag is aggravated and the gas, due to its pressure, comes to the surface. In the case of shale gas, however, the gas is trapped in the stone and does not pour naturally, so you have to pour. Hydraulic fracture, known in English as fracking, is used for this purpose.

What is hydraulic fracture?

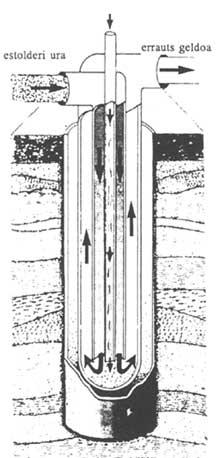

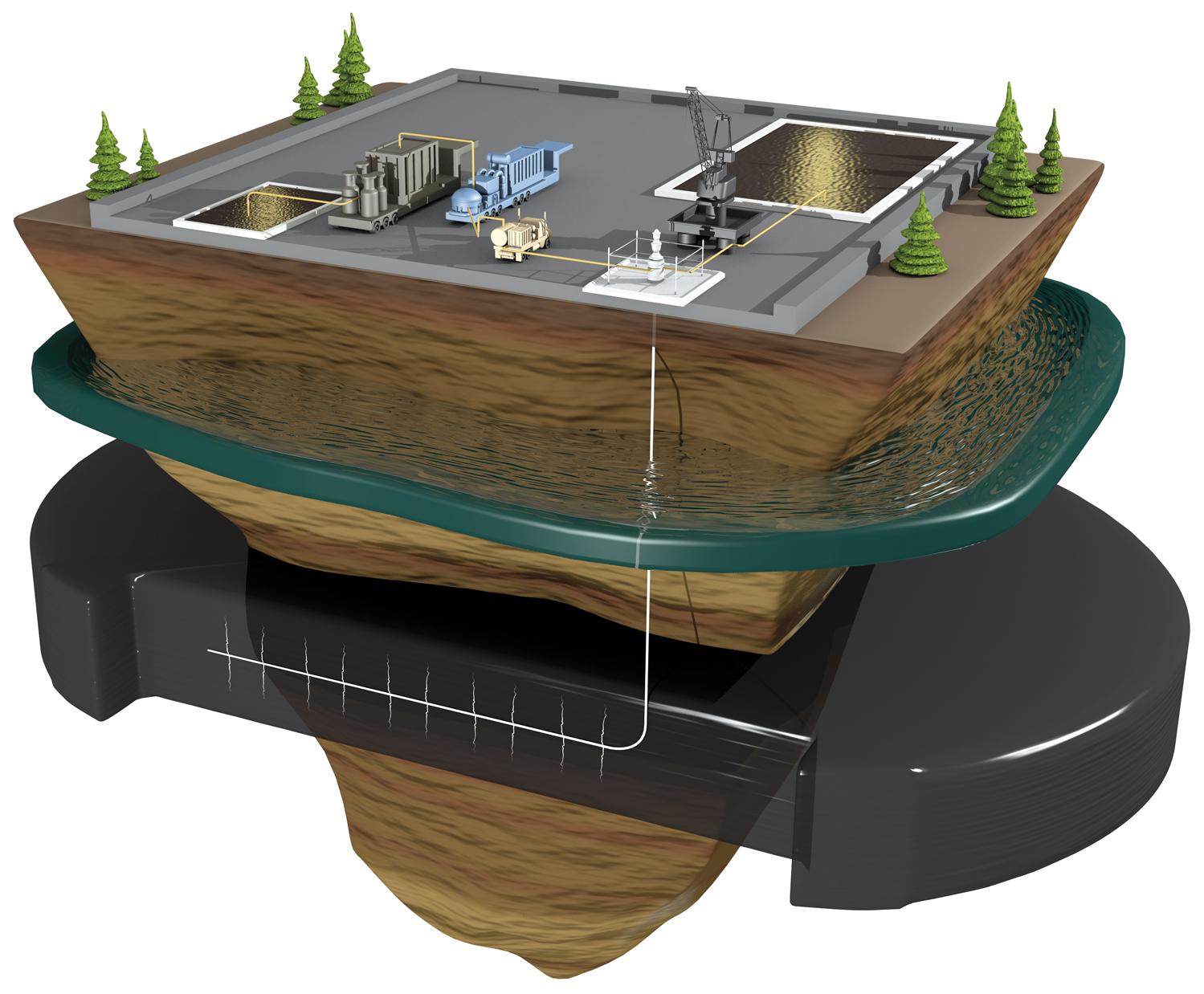

To extract the gas trapped in the stones it is necessary to drill the soil until finding the rock layer containing the gas. When 40 years ago this technique began to be applied, only vertical wells were drilled. Now the most common is to drill also horizontal. The hole is initially done vertically until it reaches the desired depth and then the horizontal galleries are drilled. These galleries can reach a mile and a half. Once the hole is made, a pressure liquid is injected, usually water that breaks the stone. The liquid penetrates the cracks and fissures generated, breaking the stone in greater detail and exposing a greater surface. Along with water a containment agent and chemicals are injected. The containment agent is a material such as silica, whose function is to prevent open crack closure and fissure.

Chemicals can have a proportion of up to 2% of the injected mixture and can be emulsifiers, viscosity controllers or biocides.

Finally, all injected liquid is extracted, leaving the surface of the exposed rock, and the gas is poured, storing on the surface.

Environmental impact

Hydraulic fracture generates great environmental concerns. In the U.S. there is an intense debate about the safety of this technology on the street, in the courts, in political decision-making centers and among scientists. For example, the Scientific American magazine of October 2011 offered the subject an editorial with the following representative title: " Safety first, fracking second ". On the other hand, the U.S. Environmental Protection Agency is carrying out a thorough field study and the first results are expected in early 2012.

Shale gas extraction projects are more recent in Europe. However, they are not liberated with controversy. In France, for example, hydraulic fracture has been banned. The British government has rejected the moratorium requested as a result of the study conducted by the Tyndall Institute of the University of Manchester. Likewise, the report "Impacts of shale gas and shale oil extration on the enviroment and on human health", promoted by the European Parliament, shows its concern for hydraulic fracture, both on its possible negative effects and on the lack of regulation existing within the European Union on this technique.

The environmental impact of hydraulic fracture can be very varied. On the one hand, methane poured from the stones can traverse layers of rock on shale and contaminate aquifers, endangering fauna and human water supply. Chemicals are used in large quantities. In a single horizontal gallery, depending on its size and nature, it can be used between 57,000 and 230,000 liters. Chemicals used can also contaminate aquifers. Huge amounts of water are also used. In a single gallery you can use between 7.5 and 15 million liters of water.

On the other hand, the water extracted from the wells, approximately 75% of the injected, is stored in surface ponds. This water, in addition to having a cocktail of chemicals, can contain radioactive materials dragged by the subsoil. The water is stored in these ponds until its transfer or reuse to the treatment plant. Do not forget that this water could end up in the environment due to inadequate waterproofing of the pond or overflow of large abrupt precipitations.

Finally, it should be noted that drilling towers, wastewater lagoons, auxiliary infrastructures, road infrastructure for vehicle maneuver and access to the site generate a high occupation of land and a significant landscape impact.

Final conclusion

I am clear that before starting to extract the shale gas from Alava several things are necessary. In-depth, independent studies should be conducted on the potential adverse effects of this technology. In addition, the application of this technology will require precise and rigorous regulation, as is the case of chemicals injected into the subsoil. It also requires a transparent and leisurely social debate. I believe that the decision corresponds to society and not only to political or business leaders. In fact, the debate goes beyond the dichotomy "extraction or not of gas", because our development model and our energy sources must also be debated. The Lehendakari statement in Texas, "there is enough gas for 60 years," indicates a development model we have today. And I believe that this model must be changed at the root, one of the pillars is renewable energy and not fossil fuels.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia