BioSasieta: energy from waste

2000/05/01 Roa Zubia, Guillermo - Elhuyar Zientzia Iturria: Elhuyar aldizkaria

The fuel of the generators will be the gas emitted by the garbage (methane, mainly) and the electricity generated will be used in the houses. The project is the responsibility of the BioSasieta society created by the EVE and the Commonwealth. If the project works properly, Tolosa garbage could also be brought to this landfill.

In the Basque Country there are two other facilities to produce electricity from waste. They all began to work with the support of the EVD. The first, BioArtigas in Bizkaia, has as its raw material the waste collected in the landfill of Bilbao, which was launched in 1992. The other is Gipuzkoa's BioSanMarcos, later and with a somewhat different process. Both projects have been pioneers at the state level in this type of renewable energy.

How do you get it?

BioSasieta will have the same system as the previous one. The base is very simple. Separating paper, plastic and metals, the majority remaining is organic matter, mainly food. When this matter accumulates it is in an oxygen-free medium. Gradually it is fermented by the action of local microorganisms. Fermentation occurs without oxygen, so a mixture of gases is generated mainly by methane. This gas mixture is called biogas. In general, biogas will be collected and used as fuel for large electric generation engines.

But in view of the procedure, other factors must be taken into account. By law, landfills cannot emit methane into the atmosphere. Therefore, if it is possible to transform energy, better. But biogas is not a simple methane. Before the construction of the plants in operation, a biogas analysis was carried out. The most abundant components found are methane, nitrogen, carbon dioxide and oxygen, but in less concentration have been found other compounds such as sulfur acid, toluene and other hazardous compounds. Determining the degree of humidity was also essential for the organization of the procedure. Water, organochlorine compounds and sulphhydric acid are corrosive. In high concentrations they can produce substances (hydrochloric acid, etc.) that can damage engines. Therefore, biogas cannot be used without further.

After the analysis of biogas from BioSanMarcos it was decided to enrich the mixture with natural gas. This is one of the features of this installation. For the control of the biogas source, the main components are detected by sensors and the optical fiber will be responsible for sending information to computers. From there, for example, you can adjust the concentration of methane input.

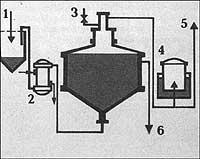

It is not a complex process. Gas is sucked into wells. These wells are linked, individually or in pairs, to biogas transport lines to the general collector. The amount of oxygen and methane is first analyzed. The control is done by automaton located in each of the lines that leave the wells. In addition, there are condensate purging systems and a separating cyclonic boiler on the main collector. The gas goes from there to the extraction plant.

System leaks

In some cases, maintenance and breakdowns require not to transfer methane to engines. Instead of interrupting the flow, it burns in the torch before its emission into the atmosphere. In fact, the methane spill is limited by law, as it participates in the greenhouse effect. The temperature and flow in the torch are measured and sent to the computer. This data is necessary because the torch must maintain a minimum flow rate.

For engines to last long, biogas must be completely dried. That is the next step. It passes through the biogas dehumidification plant. In this installation the gas cools up to 20ºC. Then the drops are separated and the gas is heated again at 50ºC. From here, the gas is filtered and transferred to continuously operating motor alternators to generate electricity. BioSasieta will have a single engine of 475 kW of power. Over the years, the aim of the company will be to set up new equipment.

Sending signals with concentration information to the engine alternator automation. According to the information collected in the torch, the gas flow introduced in the engines must be adjusted. To do this, the sensors and valves found throughout the system are interconnected by optical fiber and controlled by a computer. The personal computer (PC) is enough to perform such tasks. This measures and accumulates pressure, temperature and flow at all points of the system.

On the other hand, the installation has numerous safety elements, including landing, gas leak detectors and protection areas to prevent explosions.

Production for all

The electricity produced by BioSasieta will be sold to the network in the Special Regime in accordance with the Royal Decree on the production of electric energy through renewable energies. This electricity will be supplied for approximately 8,800 people. In the first year the engine will produce 2.3 million kWh and an income of 25 million pesetas is expected, in the second year 2.8 million kWh and in the third 3.4 million kWh. A second motor alternator is expected to be installed in 2003. This engine will have similar characteristics to the previous ones.

It is an old question about what can be done with the huge amount of waste produced by our society. This is the perfect solution. Use of the landfill. Perfect. But this renewable energy requires in part that we all work. In order for biogas to be profitable, it will be necessary to make a distribution of the types of waste more exact than that offered by our custom. Therefore, the challenge is everyone's.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia