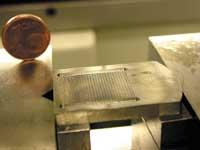

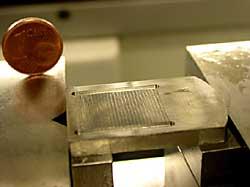

Minimum heat exchanger

2002/12/30 Atxotegi Alegria, Uhaina - Elhuyar Zientziaren Komunikazioa

This heat exchanger works the same as conventional heat exchangers, but not as conventional heat exchangers. In size it is much smaller: It enters an area of 4 cm². Thanks to this, Tekniker researchers believe that it can be applied in microelectronics. The accumulation of heat in small microelectronics cores is usually very high and, if you do not want to spoil the systems, it is essential to eliminate all that heat. To do this, a small size exchanger, which can sweep a lot of heat can be very appropriate.

Tekniker collaborates with the Eduardo Torroja center of the CSIC, the Carlos III University and Sener. The microcompactor is still in a prototyping phase, but is expected to serve for large thermal powers. It has been calculated that it will work with powers of 100 W/cm 2.

Not only for microelectronics

Tekniker researchers believe that a device of this type can have applications in areas other than microelectronics. For example, the possibility of making garments with an autonomous air conditioning system has been proposed. These garments would be used in contaminated areas or in deterioration zones for cleaning.

Also in the automotive sector, Tekniker has suggested that it can serve as an alternative for air conditioning. In fact, the automotive sector is studying the possibility of changing the traditional air conditioning equipment. This equipment, currently, is based on mechanical compression cycles and its gases, in addition to polluting the atmosphere, cause climate change and pierce the ozone layer. From now on they want to replace this type of cycles with cycles of absorption.

Tekniker, together with Sener, has been responsible for the design of the prototype, manufacturing problems and design for production. The others have created a theoretical model for the microtransmitter that allows to compare experiences with simulations. In this way, if at some point this model fits reality, the thermodynamic behavior of a second microtranslator could be optimized.

www.ihobe.net

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia