Clothing, first protection

Since when do people dress up? There is an explanation in the Bible, but scientists do not agree to answer this question. Some believe that our species, the Homo sapiens, invented their clothes when it migrated from Africa to colder areas. They say it prompted them the need to protect themselves from the cold.

But the garments are also useful in hot spots, as they serve to protect themselves from external agents and show their role within the group, among other things. For this reason, many researchers believe that before leaving Africa they were also going to dress. And in addition to Homo sapiens, it is very likely that the Neanderthal man used some clothing, since it was very cold in place and time.

Therefore, it is not clear when the man began to dress. Anyway… what did they wear? This question does not generate so much discrepancy and anthropologists consider that they used skin, leather and leaves or grass of animals.

However, they do not have many tests, since the leather and vegetable tissues are easily degraded, unlike the useful and jewelry made of stone, metal or bone. The needles, yes, have been maintained until today. The oldest sewing needles that are known are bone and gunpowder, and between 30,000 and 26,000 years ago. But the clothes are before the needles and therefore do not give clues about the first.

Skin at first

According to experts, hunters were the first to use the skins to dress. The human groups living in temperate climate zones were mainly fed with fruits and plants, and did not need to dress so much. For those living in cold climate zones, but hunting was important. The meat of the animals needed to be well fed and it is presumably that they used their skin to protect themselves from the cold.

In fact, in the deposits of the Lower Paleolithic, sylex knives and raisins have been found, which served to prepare the skin. Through them the skin of the hunted animal was removed and peeled and cleaned. But this work was not enough for the skin to work, since if not treated it would rot immediately.

With time and experience, they invented techniques to transform the skin into leather. Dried, smoked, deposited on trunks of trees, submerged in marshy waters... they saw that the skin becomes more annoying and lasting. Without knowing how and why that happened, they took the first steps in the furrow.

Since then technology has evolved constantly, but for many, the skin has not lost value. The tendency is contrary: for some it is unacceptable to use animal skin to dress, since there are many other materials to make clothes.

Old and current wool

Wool, for example, has been used for a long time and no need to kill any animal to get it. It is believed that the Neolithic agricultural-cattle rancher started spinning wool and has several advantages over leather. The wool is elastic, light and even durable. Who does not have a favorite jersey, the most beloved of all for being old? It is clear that the wool garments last a long time.

In addition, the wool adapts better than the skin to the weather characteristics of the moment, especially to the humidity levels and to the temperature changes. In fact, wool fibres are curly and between the curls air enters and remains there. Inert air is one of the best known insulators, so wool protects well both from cold and heat.

In addition, the wool absorbs water vapor. The main component of fibers is a protein, keratin, surrounded by overlapping scales. Keratin can take a lot of water, about 30% of its weight before getting completely wet. In cold weather, it absorbs the humidity of the air that is trapped between the curls, keeping dry the layer of air close to the skin of the person and, therefore, the wool clothes do not lose heat.

In warm climates it favours the process of perspiration / / evaporation. Sweating is the natural mechanism of the body to lose heat: when the sweat evaporates, the temperature decreases in the skin. The wool contributes to this, on the one hand absorbs the humidity of the sweat and, on the other, the scales carry it to the outside.

It is also very suitable for sudden changes in temperature, since the heat and humidity exchange between wool and the environment is progressive. The scales also protect from erosion and from the entry of liquid water and, as if that were not enough, the wool has a layer of fat, lanolin. Thanks to this, to some extent it is waterproof and although the sirimiri leaves the wool suit made a mela-mela, it holds quite well the shell without getting wet.

Tissues of vegetable kingdom

Together with fibres of animal origin, those of vegetable origin are used for a long time: linen, cotton, hemp, jute... Flax fibres, for example, are used before wool itself to make fabrics. 5,000 years ago, in Mesopotamia and Egypt, yarn and weaving technology was very advanced, and flax was used to make elegant garments and hard cloths.

Flax seeds are also valuable as oil is extracted from them, but in the manufacture of fabrics the fiber of the poles is used. Flax fibres, 30 to 75 cm long, are formed by individual cylindrical cells. One of the characteristics of linen fabrics is its softness. In addition, it is sustainable and difficult to break. It easily absorbs moisture, but dries quickly and is a good heat conductor, making it ideal for hot spots.

Cotton is also fresh and durable. The cotton plant grows in tropical and subtropical climates and, like flax, is used in the textile industry for thousands of years. Cotton fibres are produced when the flowers die, outside of the seeds, wrapped in the form of a ball.

The cotton balls are formed mainly by cellulose (87-90% cellulose) and after several treatments of elimination of proteins and wax fibers are formed by pure cellulose. Its winding and fabric fabrics are ideal for making clothes and underwear for hot places, as they absorb moisture and are very comfortable and fresh. For cold areas, cotton is combed to obtain warm, hairy tissue.

At present, technological treatments allow to give cotton any characteristics almost desired: not to ruin, waterproofing, etc. Therefore, it is not surprising that about 40% of the natural fibers of the textile sector are cotton.

The oriental charm

Although cotton is widely used in the textile industry, many believe that it cannot overcome the charm of silk. The silk is smooth, shiny and slippery, symbol of luxury since ancient times.

When the worm is ready to become a chrysalis, it begins to make a silk bud. To do this move the head in the form of 'eight' and two glands near the lower jaw secrete a liquid. In contact with the air, this liquid solidifies and transforms into silk thread. At the same time, the worm secretes a rubber that binds the two filaments. In three days it transforms all its liquid into silk. In a hood 1,300 meters of silk thread are collected and 5,500 worms are needed to produce a kilo of silk.

Cocoons should be treated to clean and work silk. The threads obtained at the end are very light, durable and resistant, elastic and non-flammable and the fungi do not attack. But not everything is favorable: you have to wash the silk by hand and with cold water, bleach harms it, wrinkles easily and you have to iron carefully.

Artificial and synthetic fabrics

Trying to imitate the most appreciated characteristics of silk, in 1892 the French chemist Hílaire Berniggaud invented rayon. It was the first centenary

Since then, the industry has created eleven artificial and synthetic fabrics.

Synthetic tissues are formed by reaction of small molecules through a process of polymerization. In this process, the units called monomers join each other forming complex molecules, that is, polymers. The polymers have adequate characteristics for the textile industry, since they are light, durable and elastic. It is used not only in the textile industry, but in many other areas.

The first synthetic fabric, nylon, was marketed in 1940. Wallace Carothers invented it five years earlier by polymerization of a beloved. This polymer easily gave filaments, but the first nylon product that came out on the market was not a fabric, but a toothbrush with nylon bristles. It was the year 1939. Two years later, DuPont launched on the market the product that completely revealed nylon: nylon socks.

The future at its peak

The researchers' efforts are giving spectacular results. An example: transparency suit. With this costume, as with looking through a window, you can see background scenes as if there was no one among them.

The secret is in the material of the clothes and in the work of a camera. The camera is behind the person wearing that special clothes. From there it takes the background images and projects them in the clothes. The clothes are made with a photographic material that clearly reflects the images. In this way, it seems that the person who has her dressed has become transparent. It seems magic, but it is only technology.

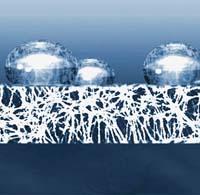

There are more practical examples. There are many who dream of clothes that are cleaned on their own. The researchers have tried different ways to devise this type of clothing. For example, by introducing in cotton nanoparticles of titanium dioxide. Under ultraviolet light, titanium dioxide releases electrons. These react with the oxygen of the air generating free oxygen. Free oxygen is very reactive and breaks down organic matter -- dirt --. The result of the reaction is carbon dioxide and water.

Clothing has also been invented against the smell of sweat and pathogenic microorganisms. In this case, the N-halamines have been introduced in cotton. N-halamines contain chlorine atoms that kill bacteria and other viruses that produce the smell of sweat.

Nanotechnology has become a useful tool to give fabrics the desired characteristics. On the other hand, together with electronics, they have achieved costumes that look like science fiction. They are called electrotissues or smart garments and have eleven applications: the heart rate, clothes that measure the concentration of glucose in blood and the degree of hydration, which are heated electrically, garments that change color when running according to the speed of the corridor... The future is here.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian