Ulla-Førre: power output to water

1988/10/01 Aizpurua Sarasola, Joxerra Iturria: Elhuyar aldizkaria

In this century engineers have dug in Norway about five hundred lakes. If the Norwegians accept the risk of lake drilling it is because they have given up nuclear energy. Since the accident at the Chernobyl plant, the commitment to hydroelectric power has intensified. They continue to import energy from Sweden and Denmark. These three states are connected to an electric grid. Thanks to this, in large rains or snowfall, Norway exports energy and, instead, imports it in summer.

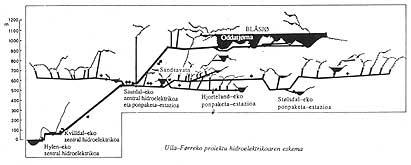

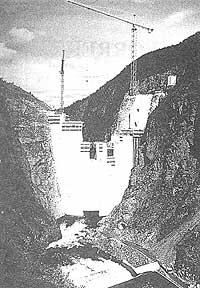

The Norwegian topography, on the one hand, and the fact that the decision to burn oil is as little as possible, open all roads to hydroelectric projects. The hydroelectric project that is about to end in the southwest has the reservoir at 1000 m altitude and in it there is snow throughout the year. In this project, called Ulla-Førre, 125 km have been built by tunnels, more than 50 walls and communications between 30 lakes. The walls are made of morro and cement. One of them, Storvassdammen, is 90 m tall and 1.5 km long. It is the largest in the world. Accumulated snow and rain exert enormous pressure on the structure. The maximum theoretical energy of the Ulla-Førr generators is 12,000 gigawatt hours. The expected average annual energy is 4500 gigawatt hours.

The Ulla-Førr project began 20 years ago and its cost is estimated at one hundred and twenty billion pesetas. The idea is basically: Grouping of eight lakes for the creation of the reservoir called Blametsjø. Blametsjøwill have an area of eighty-seven square kilometers and it is expected that the Norwegian southwest, which houses most of the Norwegian population, will supply electricity throughout the year.

When the energy demand is not very high, the water level can exceed a wall in five meters in lakes or reservoirs. To prevent this from happening, pumps (those that work backwards and perform the generator function) can raise the water to five hundred meters, that is, up to the Blametsjø, as shown in the image.

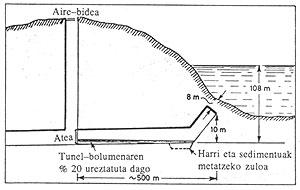

Blametsjøhas 12 walls and can store 3105 million cubic meters of water. For the communication of the eight lakes that form the blametsjø 19 tunnels have had to be opened. Unplugging a lake to build a communications tunnel is dangerous and complex. When the depth of the lake is high, great discomfort occurs in the construction of the tunnels. Oddatjørna is the deepest of the eight lakes forming the Blametsjø, 108 m.

The best place to drill the lake is the solid rock bottom and fine sediment. Geological maps, seismograms, etc. are performed. As the tunnel approaches the lake, the lake water begins to flow into the tunnel. Should the rock suffer any defects, the tunnel personnel would be in grave danger. Therefore, the last meters of the tunnel are drilled manually and the working conditions are harsh, since the water reaches the knee.

The pumps work continuously to extract the water flowing into the tunnels. In this situation they must act until the end of the tunnel and on many occasions this process takes months. The tunnels have steel doors to control the flow. If any of these doors failed, the machinery would be endangered with the force of water. Cement and some chemicals are used to reduce water leaks from cracks and fissures.

To drill the last part, explosion-skilled personnel place the explosives. Explosives can survive today, as long as the equipment is ready. After the explosion, the water enters the tunnel with great force, dragging sediments and fragments of rock. All this can cause serious problems in turbines and generators, which can be avoided by placing temporary barriers or by making holes in the place where the blast is to be performed so that the drag accumulates. Another sediment sinking technique in the tunnel is to water 20% of the tunnel volume before the explosion. This water, with the steel door closed, compresses the air from the tunnel, causing the sediment to sink into the tunnel.

The rapid decrease in the water level of the excavated lakes can cause problems in the surrounding grounds and walls. Therefore, before the explosion engineers must be sure of the stability of the floors.

Surprise the total emptying of some excavated lake. However, engineers left Ulla-Førr's Sandsavatn Lake for a winter to collect snow in the coming spring. In addition, they had the opportunity to see the communication hole and when they realized that instead of having 50 square meters only had 30, they increased the size of the hole. When nature filled the lake again, the water did not catch the dark blue color of before, but the dark green. The reason for this was in the glacier sediments, which formed a colloidal suspension.

Although the surrounding fauna was not affected by the water change, nature watchers were not closed. However, what happened on this lake was nothing more than a curiosity about real problems. Discussions between designers and conservatives of nature have tried not to cut the paths of reindeer and salmon and restore the deteriorated areas. But the problems have not ended. The drops of water from the fog banks created around the hydroelectric plants stick to the buds and freeze quickly. This causes the death of the buds.

Every year fishermen eat about 2000 kg of salmon in Ulla-Før. The project has taken this into account. We are not sure if they have done so for the interests of fishermen or for economic interests.

Around 3000 artichokes live around Ulla-Førr and a 100 m high wall was not built because the roads used by these animals during migration were interrupted. The project to build a Statkraft bridge, Norway's main energy company, was also abandoned, as snow deer dared not cross it.

In Norway, Ulla-Førr is not the only hydroelectric project. There are at least three more, Alta, Josetedal and Kobbelu. Hydroelectric plants that must be built on land of the Arqutiar Polar Circle present special risks. They say the lands speak. This phenomenon is well known in the mines of South Africa. Rock jumps are frequent in tunnels and as a result of them serious accidents occur.

Despite the progress of automation, many times staff must work by hand and in difficult conditions. But the result is there: an inexhaustible source of energy.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia