Machine tools: revolution and crisis

In Europe machine tool manufacturers began to unite around 1950. It was then that the first Machine Tool exhibition was held in Paris. First only Europeans could participate, but since then manufacturers around the world have the opportunity to publicize their products. It is held every two years in Hannover, Paris and Milan. The last, the ninth, was held in Paris in June last year, where you could see the steps that have been taken lately in machine tools.

The truth is that the news of these advances do not appear as bright as space driving lasers, scanners or bombs, but we must not forget that they are changing at the same speed as these. The machine is an increasingly productive, increasingly intelligent, increasingly automated tool. But what is the machine tool?

Role of machine tools

We all know that alternator, crane, car, plane, computer or washing machine are machines. Machine tools are those in the industries in which they are manufactured. Milling machine, lathe, surface polisher, boring machine tool function, drawing press, brush, etc. are called.

They shape raw parts or sheets (steel, casting, plastic, wood, etc. ). Through their tools they make the parts of the machines we use in our daily lives, cutting, scorching, folding, etc. material.

Take for example a telephone device. These plastic parts have been extracted from a mold but milling, grinding, polishing, etc. has been performed. from a rough piece of steel or cast iron. The cylinder head of the motor of the car, for example, is a piece extracted from a mold, but the mold has been prepared with machine tools, among other things: the milling machine has drawn the shape of the cooking shrimp, the drill has drilled the valves, the boring machine has finished the holes, the threading machine has ceded the holes to tie the spark plugs, etc.

Inside machine tools you can make many families or series with dozens of different types. In addition, every day they are extracting new machine tools adapted to new applications. And no wonder, considering all manufacturing areas that are used. In fact, from the 50 ton pieces of giant presses to the tiny gears of the watches have to machine everything.

The tools that shape the parts are also of a thousand forms: steel brush for punching the plate, blade that lifts the chip on the lathe to machine the cylindrical axis, abrasive stone that rectifies the teeth of the gear, drawing die, threading shaft, etc.

Smart Machine

Numerical control (CD) has incorporated intelligence into machine tools in recent years, but at the same time the number of machine tools has been reduced. Numerical control has provided skill and flexibility to machine tools by its machining program. This program sows this type of tool at a point similar to that of the piece, then gives work to another tooth, then brakes the strawberry to 56.87 mm, etc.

All this has allowed "joining" the different machines due to numerical control. More than the sequence of milling, drilling, grinding machines, etc., it has been possible to create a "machining center" that performs the whole part.

For this purpose the piece will be automatically tied on a table that can be moved in two or three dimensions. The machining tools are also automatically attached to one or more tool holders, which have the turning speeds selected in the program. The tools are fixed in rotable turrets and carried from the warehouse to the necessary tool holder when required by the program.

So far in the mechanical factories there were twenty machine tools aligned, and small vehicles carried boxes full of semi-finished parts from one machine to another. Now it is enough to place three machining centers for the same production. Two or three technicians monitor the machining centers that work constantly day and night, attending to the wear of the tools.

In the early 1960s, with the development of computers, computing began to be applied to machine tools. Obviously, machine tools have been automated for a long time, and the different functions were performed without the participation of people, but the adjustment of the machines was done in time for the automatisms to be connected.

We will explain it by example. Suppose a brush had to make a hole 40 mm deep. When dipping 40 mm it had to have a stop to stop the bit displacement. The operator, however, had to select the drill bit and apply to the machine both the turning speed and the feed speed taking into account the material to be drilled. With all these preparations the machine worked automatically.

However, by numerical control, a computer constantly records the bit displacement and a program has the following instruction: "Stop drilling 40 mm". This instruction can be dictated as follows: "stop when the axis that moves the drill house turns 10.25 turns". The program simultaneously sets the bit turning speed and feed speed.

Advantages of numerical control

Comparing the physical phenomena that occur in the machine with the orders inscribed in the computer program, machining operations are automated without having to set speeds that must be respected in the machine itself. This allows that once the machining of a part is completed, the next part starts automatically without the intervention of the operator. In some cases, also, obtaining precisions of a micron.

Regardless of what is gained in speed and flexibility, numerical control overcomes the obstacles of conventional machining in terms of quality. Here are some of the advantages:

- The lack of skill or skill of the worker does not affect.

- The parts need not be manufactured in large series. To rule out the preparatory work to be carried out on the transfer machines from one type of piece to another in conventional machining, large quantities of one type of piece to another were used. However, by numerical control he has made 20 pieces or made 20,000. There are no cost differences.

- Part drawings made long ago and machining conditions are much easier to find. When they request a replacement due to deterioration of the part made five years ago, for example, all the data and machining conditions of the part are in the memory of the computer. Once the data is entered into the appropriate machine, the part can be done immediately.

Although the CD was at the beginning of about twenty-five years ago, today due to its advantages, 60% of the world's production of machine tools has become numerical control.

Technical machining bars

Machine tools, as already indicated, can be of a single function or machining centers, but the part is usually always worked by forming or starting chip. However, in the last fifty years there have been technical machining bars. The most important are:

- Electroerosion. It is machined by skipping the electric arc between the part and the tool. The tool is the thread or needle that passes through the piece normally. It makes a hole, for example, but it doesn't have to be round. Square or polygonal holes can also be made equal.

- Chemical machining. It is an electrolysis.

- Shaped in explosion. A sheet metal projection on the die forces to adopt a particular shape and relief. The same result can be obtained by introducing the incompressible liquid at high pressure.

- Laser machining. In it the energy of light eliminates the particles of the part to be machined. High precision parts are obtained.

- Ionic machining. The accelerated ion beam works as a laser.

This type of mechanization is improving day by day. Sometimes they are even combined to achieve precision or improve costs that cannot be achieved through classic procedures.

Advances in computer science

The exhibition held in Paris last June saw the latest advances in numerical control of machine tools. More compact and rich programs have appeared, especially thanks to the use of 32-bit programs in microcomputers. So far, with 8-bit or 16-bit programs, the computer could not govern many functions.

Ten axis numerical controls have appeared at the Paris trade fair. Let us clarify that at the beginning of the CD there was a single axis (for example, numerical control only controlled the dimensions of the "x" axis), two and three (countered three dimensions).

Of ten axes does not mean that we have a space of ten dimensions, but that the program governs ten functions. In the same machining center, in addition to the directions of the three axes in coordinates, machined with two or three different inclinations, another two or three functions for the handling of tools, etc. can exist. All this thanks to the 32-bit memory of the computer.

Advances in skill, flexibility, and accuracy are due more to speed in information processing than to machine design. It is about performing all machining tasks while the part is in one place. Therefore, turning, milling, broaching, etc. of the piece in the same place. become "flexible cells". Of course, this cell requires a large number of tools to hand around.

200,000 revolutions per minute

In addition to the advances in the field of computer science, in other functions usually fulfilled by the machine tool, new developments were also seen in Paris. For example, the cutting speed (relative speed between the part and the tool) is increasing. On the one hand, machine organs are getting better (bearings with roller bearings, air bearings, anti-vibration structures, etc.) On the other hand, much progress has been made in cutting tools (from the manufacture of fast steel to the manufacture of tungsten carbide, boron nitride, diamond, ceramics and cermet).

The cutting speed remained for a long time between 15 and 40 meters, but since the sixties, between 80 and 100 meters, it has been quite normal. In recent times, and especially thanks to studies carried out in Germany, speeds have been reached from 400 to 500 m/min and in light alloys it is expected that soon they reach 800-1,000 m/min.

As for the speed of rotation, between 50,000 and 60,000 revolutions per minute are used and in machine tools of hyperprecision between 150,000 and 200,000 rpm are expected. with air bearings.

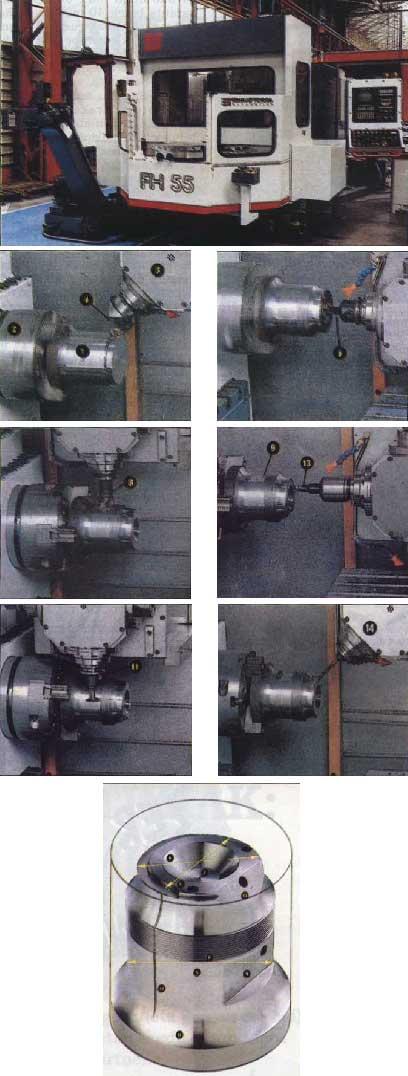

In the figure you can see a machining center governed by numerical controls. It is well protected to prevent chip and machining oil from going outside. The part to be machined (I) is a steel cylinder. It is tied to the plate (2) that spins the machine. The different tools needed to mount the chip, (3) are mounted on the tool holder. When the machine rotates the part, the turret gives a piece back in each operation to bring the corresponding cutting tool closer to the part at every moment. The operations to be performed in this machining are: External turning. (4) by placing the tools in parallel from the axis of the part, it will lift in each pass the chip until reaching the desired diameters A, B and C in the piece. Threaded. Another cutting tool (here is not depleted) (5) will thread the part to a certain length of the cylinder. Internal turning. The turret then presents (6) the tool and mechanizes at the top of the piece (7) the sako's instant. Milling. The turret (8) brings the strawberry to the piece. Cut two planes: (9) flank and (10) high, inclined. Subsequently (11) the strawberry (12) mechanizes the narrow groove. For these milling operations, as well as for the rest of subsequent operations, the part remains the tool that turns. Drilling. Holes (13) and (14) are made with bits. One hole is perpendicular to the axis of the foot and the other inclined (14). Thanks to numerical control, all these operations are carried out automatically in this order, respecting the pre-programmed and fixed dimensions on the part (in addition to the micro precision on some machines). Choice and placement of tools, turning speed, feed speed, drilling depth, etc. are program instructions.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian