World Environment Day

In fact, when in 1972 the United Nations Conference on the Human Environment proclaimed this day in Stockholm, its main objective was to raise awareness about the importance of the environment and the need to preserve water. To do this, groups and organizations working in the defense of the environment usually organize very diverse symbolic activities.

On the one hand, we are becoming more and more inhabitants in the world, 78 million more people each year. On the other hand, until a few years ago, few saw nature or the environment as an element to be preserved (exploited) and, moreover, as a deposit of inexhaustible resources. Adding to these three elements the local peculiarities and conditions, the deterioration suffered by nature has been really intense. For example, today, according to the most optimistic calculations, 27,000 species of living beings disappear every year, 3 every hour. And scientists believe that in the next 30 years 20% of all species can disappear. The fastest destruction suffered by nature!

In Euskal Herria numerous species have also disappeared under the pressure of the human population and many of our landscapes are completely deteriorated (inadequate constructions, contaminated waters and lands...).

But in recent years things have begun to change. It seems that society has gradually become aware of the importance of nature and the environment. For some reasons are aesthetic and sentimetals or philosophical, but for others there are natural, ethical or scientific reasons. In addition, in its eagerness to adapt to this world that measures everything in money, or to maintain commercial and economic value for nature conservation (in Navarre, nature reported more than 14 billion pesetas of profit last year). Without a doubt, people's awareness is very important and must be promoted, but in short, money is what "decides" to move things (or not) and that ecology or the care of nature are profitable in money has a great importance when making solid decisions.

As the change of focus of nature and its knowledge expand, the environment itself is becoming one. We are learning that everything is interrelated and that the damage that occurs in a certain territory, place or environment, or the pollution emitted can affect many other territories, places or environments, although in many cases it depends on the damage. That is, the radioactivity released by the accident of Chernobyl was measured in many places of the world (even in the Basque Country, despite being 2,500 km in a straight line); or many of the birds poisoned by the accident of Alnazcollar move to Doñana, but also, with the arrival of spring have dispersed throughout Europe, opening up the pollutants in a few kilometers or traveling to Labona 6. And following this we can reduce the scale, but whatever is done, it will always have some impact. And even though what everyone has done is a drop of rain, we all know what happens when many raindrops come together: the flood. In addition, if these raindrops are contaminated, in the end the flood waters will be dirtier and even if the flood does not occur, water drops can extend the pollution to many places.

However, in many cases, since it cannot affect the whole environment, it is necessary to control certain factors that affect the environment in our near environment. These factors are several and one of them, very important, the industry and the waste generated by it. In this sense, in recent years Clean Production plans have been implemented in companies such as reducing pollutants generated in them.

Clean production in the Basque Country

The industrial sector, from an economic point of view, remains an important sector in several territories of the Basque Country. And every industrial activity, as a result of its production process, generates to a greater or lesser extent waste that is generated mainly for two reasons: 1) because of the difficulty of using 100% of the main raw material (for example, the non-generation of scrap in the process of machining metal parts) and 2) because of the need for auxiliary raw materials that are not incorporated into the product in the manufacturing process and that once left of being useful become waste. The relationship between waste generation and industrial processes is therefore inevitable, but the volume of generation will depend on the efficiency of the process. As efficiency increases, the amount of waste generated decreases due to the better use of the raw materials used.

In the factors of being more "clean", the economic benefit of this development has undoubtedly been very important. In many cases, the reduction of waste generation and productive performance are the same, that is, a more adjusted use of energy and raw materials (and therefore lower initial expenditure) and the reuse or treatment and valuation of the generated waste.

As in other countries, in Euskal Herria we have begun to notice some change in the concept of company. In fact, companies have begun to see the natural environment as a good that is acquiring an economic importance and productive processes begin to be, by conviction or by chance, cleaner. To do this they have implemented different plans in different companies.

Clean production: What is it? What are your goals?

So far, however, they are general considerations, necessary before any action, but they are nothing more than that, so we arise several questions. For example, what is the clean production we have mentioned so far but have not explained?

In short, prevention. The word and solution we have used for years has been debugging. Some waste has been cleaned, cleaning the water or air from the spill, but finally, despite having a smaller volume, a more concentrated waste is generated than the initial one. This is merely giving an intermediate solution to the problem and partly delaying the problem. Another more interesting option than the previous one is recycling or reuse. Reuse of waste by treatment or without treatment. This path is very interesting in some cases, such as glass, since the cycle of using (recycling) can be endless. But sometimes the cycle is less efficient or indirect waste is generated. Therefore, it is logical to think of an alternative that goes beyond, that does not generate waste. Prevention. And prevention is clean production. The philosophy is to improve the efficiency of the production process, improve the performance of use of raw materials and reduce the volume of waste generation, in order to minimize the environmental impact and therefore improve the quality of life of all of us. And all this, often obtaining an economic benefit. Nice not? Beautiful and achievable.

However, the generation, generation of waste, but in the problem of pollution caused by waste, only once the possibilities of action in origin have been exhausted will proceed to evaluate the needs of recovery and reuse or treatment of waste and emissions generated. In this case, reuse and, if not possible, the treatment of waste are also positive attitudes, but always considering that the latter have less environmental interest than clean production. In addition, we all know that repairing is more expensive than avoiding, regardless of the point of view.

What are the clean production tasks?

The key to clean production would be to get the same number of products, but using less raw materials and generating less waste. The measures or actions to be taken are multiple and varied, so the measures to be taken in specific cases will be decided through a thorough analysis of the production process.

In this way, in some companies the generation of a certain waste can be avoided by modifying the raw materials, in others the main point of environmental improvement will be obtained by modifying the organizational and operational and/or maintenance measures, in other companies that can reuse the waste and, sometimes, the modification or optimization of the production process and, why not, the design or composition of the same product. Therefore, in each company the situation will be different and the measures to be taken. Here are some examples:

Changes in raw materials and their use

The raw materials used and their use can have a decisive effect on the waste generated.

Substitution of chlorinated degreasing solvents by water

In a company manufacturing taps, valves and thermostats, the metal parts rubbed with oil and drills must be degreased, among other machining tasks. For degreasing the toxic solvent called first perchloroethylene (PER) was used in open machines.

To do this, the parts with oil and drill were taken to the PER tank for further machining.

To minimize waste and releases to the atmosphere as much as possible, the company acquired new degreasing tools.

This replaced the degreasing PER with water. 8 automatic machines were installed, one next to each line. The parts subsequently impregnated with oil and taladrine should not be transported back and forth in the workshop, so no drips (waste) are produced. Efficiency has been improved and oil and taladrine do not dry during parts transfer.

Organisational measures

Organisational measures significantly reduce waste generation. In addition, they help companies improve their short-term results, hardly require investments and are often a motivating element for workers.

Pickling acid savings by 38% by improving raw material storage

The effectiveness of the hydrochloric acid pickling bath is directly related to the degree of iron saturation of the oxides removed from the veneer to be pickled. When the iron concentration reaches a certain level, the bath is invalid and must be renewed. The rain oxidized this. The consumption of pickling acid in the event of the beginning of storing raw materials in a covered place, as well as the waste to be managed, has been considerably reduced.

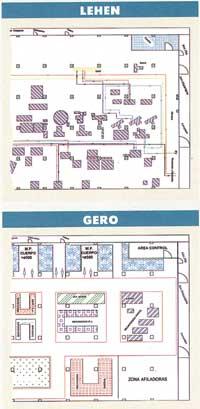

Fuel savings by moving machinery

Two companies in the Gernika area took better advantage of the occupied space and shortened the passage of the parts in the company and moved the machinery to reduce the time of passage. Electricity consumption in lighting and fuel consumption in heating were also significantly reduced. In one of the companies the consumption of heating fuel has been reduced by 50% and in the other by 15%.

Factory reuse

Most products, once used in the production process, can be reused. It reduces waste generated by reuse and saves economically by not having to buy new products.

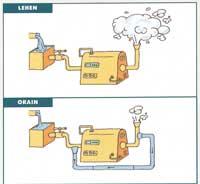

The "beneficial" idea of recycling steam purge

In the steam boilers of a given company a temperature of 170 ° C was reached and the purge was obtained at the same temperature, so part was extracted in steam phase. Some modifications have been made to the system by reintroducing steam to the boiler to make the most of it. As a result, the purge has been reduced by 50%, reducing fuel costs and reducing emissions to the atmosphere (240.6 tons of CO2 and 3.6 tons of SO2).

12% of the oil consumed is oil recovered from the chips

The chips generated during the machining of the parts carry enough oil. A carpentry company has recovered 104 kg/year of oil after the centrifuge placement. Centrifugal oil, which accounts for 12% of total consumption, is reused in the machining process.

Technological changes

When the company starts a process of technological change, it must take into account the replacement of some equipment with others more efficient from the point of view not only productive, but also environmental, which can influence the volume of waste that is generated later.

Use a less polluting oven that pays off in a year and a half

In a company in the metal sector, the parts were tempered in a cast lead bath in the fuel, then cooled in the oil bath. This process generated perforated crucible residues, splashes and lead membranes and used oils. In addition, lead baths produced toxic emissions, while fuel combustion produced gases and oil vapors.

All these problems motivated the company to change the oven. The new furnace, with natural gas, reaches 2,750 million kilocalories, and to melt and use the oil it is no longer necessary to use the previous 10 tons of lead.

These measures have meant a significant reduction in waste and emissions and a reduction in staff working hours to carry out the process. Cost savings allow to recover the investment of 19 million before year and a half.

Product changes

In addition to the aspects related to manufacturing, you can try to extend the life of the product and facilitate its subsequent total or partial recycling.

New product design makes cyanides completely disappear from the company

A company dedicated to the process of making pistols had to weld parts that formed the framework of the weapon. Before performing the darkening treatment that gives them the characteristic bluish black color of weapons, the welded pieces should be demetalized in the cyanide bath.

After a thorough analysis of the product, the components were redesigned and the intermediate welding phases removed. It was observed that these changes did not affect the final product so cyanide is no longer used in the company.

What benefits does clean production have?

The above examples already show the advantages of clean production. However, below is the list of environmental and business aspects that have occurred to us:

- Reduce the amount of raw materials and waste generated.

- Pollution reduction.

- Economic savings by reducing the consumption and cost of raw materials and the cost of waste treatment.

- Competitive advantage by improving product quality and efficiency. In addition, the business strategy is one of the main added values of the company. Environmental companies will have less difficulty acquiring land or obtaining permits, as allegations and protests by neighbors and municipalities will also be minor.

- Improvements in occupational health. The relationship between environmental and occupational health problems is evident, especially when using toxic products. The application of preventive measures in the production process allows to reduce the final generation of waste and emissions. This results in an improvement of the working conditions of the workers and, consequently, of the labor casualties, of the union claims on these issues, etc. can be reduced. It is clear that people living in the company environment will also experience improvements in their health.

- Improve the social perception of the company. And the company has to be close to the environment in which it develops its activity and thus take into account the social, labor and environmental environment. Until recently only the increase in production was emphasized, at most (and not little) some municipal sports center or similar works were performed. Today, however, the company that demonstrates its respect for the environment will have more and more social prestige than the one that does not have that image. In addition, for many companies, besides image, environmental protection has become a strategic goal.

Buletina

Bidali zure helbide elektronikoa eta jaso asteroko buletina zure sarrera-ontzian