Charcoal in antiquarian mode

1994/10/01 Kaltzada, Pili - Elhuyar Zientziaren Komunikazioa Iturria: Elhuyar aldizkaria

Lontxo Narbarte gave fire to this last txondorra in early June, but he told us that the work needed to do so began earlier. The first is the collection of wood. Although they have brought him here for the present, this morning recalls well the hardships of yesteryear “I had to walk through the forest to collect the wood necessary to build the txondorra. We prefer beech, oak or chestnut, but on more than one occasion we had to use any other wood, when we could not find anything else.”

For the construction of this txondorra it has been used mainly the beech, with an average of 50,000 kilos of wood. Lontxo has collected trucks in this plot of Lazkao, then crushed with axes, sawdust and manure. In fact, great importance is given to the correct cutting of the wood, since the structure of the txondorra so requires.

The txondorra is a cone-shaped wooden stack that is formed to make coal. However, this definition seems too implicit, knowing the work done by the carboner. The technique of coal is very precise, and that, as Lontxo said, is not learned from day to day: “You have to do it from a very young age, because you can’t learn to make coal. Being an adult you can't teach anyone, in blood, or someone knows where to write. This strikes me, because today there are no young people who build the txondorra and, therefore, when we go the last old carboneros of our generation, we will carry tradition with us.”

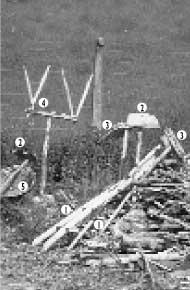

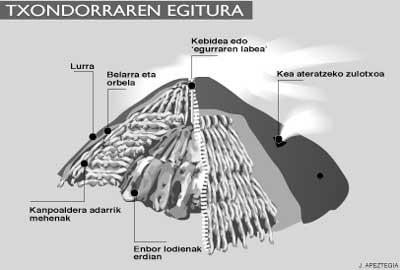

Before starting to assemble the txondorra, Lontxo has collected, stacked and crushed the wood. Now you have to carefully form a mesh structure that is the base of the txondorra. Place the post in the center as a guide and around it, four pieces of wood of the same size that will form the smoke duct of the txondorra. It is here that Lontxo places the long stick called “mayor”, which is the axis that directs the height of the txondorra.

Once placed the inner supports of the txondorra, it will begin to be constructed from bottom to top, placing the thicker stems in the bottom, thinner as above. Seen from the outside, the structure of the txondorra may seem like a spider's work and Lontxo confesses to us that it is largely: “We must be very careful to organize the structure of the txondorra well. Many times it has happened to us that, once this work is finished, before the fire occurs, everything has been chopped. This may be due to many reasons, but the main one is the poor laying of wood.”

Once the internal structure is lifted, the txondorra is covered. The charcoal will place the litter, small branches and the animal wrapped in the forest on the wooden reservoir, forming a robust structure. It is very important to cover everything well, since once burned, instead of cooking it little by little, if the wind enters, the txondorra would be totally burned and everything would be wasted. After all this, Lontxo will open a few small holes in the entire area of the txondorra to make smoke. However, the large holes that will provoke the inner fire will cover them with jealousy, as they run the danger of becoming ashes. Throughout the process, the charcoal will analyze perfectly the sense of the wind, since in case of sounding transversely it will dare to disassemble the work done.

It is only necessary to give fire. To do this, Lontxo will remove from the upper hole the mayor who has placed him next to the base: “Sometimes there has been a decline in the txondorra when the mayor was removed. You also have to be very careful. However, if what we call the smoke duct or the “wood furnace” appears clearly, we can kindle it calmly, because it means that we have built a solid structure.” At the top of the cone the brasa enters and then it is covered with a tin cap. In a few hours we will see that the txondorra is smoke and will begin to transform the interior wood. The process that occurs inside the wooden reservoir is the loss of water: little by little the fire will absorb water to the wood and has become coal. The wood, therefore, is not burned, but is cooked gradually.

As the days pass, the cone shape of the txondorra is distorted, losing height. During the firing of the wood, the charcoal will continue “feeding” the txondorra, covering the holes opened by fire and introducing smaller trunks until the cooking is completed. At this time, how does the chupista know if the charcoal is ready or not? “The color of the smoke is perceived when it darkens,” says Lontxo, “but we must also be very careful in this case, since if the txondorra is opened, the inside is lost, whether it is coal or wood.” The txondorra expands with the grid or trident, and there will appear the black coal of so many coasts.

Lontxo is unaware of the amount of charcoal it will get from the initial 50 tons. He confessed to us that you cannot know: “Someone could calculate the proportion, but I would bet that it will go wrong. With the same amount of wood you would not always get the same measure of coal. Not only depends on the wood: if you have placed the wood well, how much has lost the water, if the wind has accelerated the cooking… all this will finally have a direct effect”.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia