Brava, trains without borders

2001/07/01 Kortabarria Olabarria, Beñardo - Elhuyar Zientzia Iturria: Elhuyar aldizkaria

Narrow open roads

Railways XIX. They began to be built in the 19th century. In most European countries and the United States, after the end of their war, the engineers adopted a decision of 1,435 millimeters wide, considering that it was the most appropriate measure to transport the pull. Peninsula, XIX. In the mid-20th century, in 1848, the first railway, the Barcelona-Mataró railway, was inaugurated. Its width was 1,672 millimeters. There were, therefore, ways of different width.

In 1887 an international conference was held in Bern, where the standard width of roads was proposed, among other things: 1,435 millimeters. Spain ignored this decision and established a width of 1,668 millimeters on all roads it built. It is unclear why that decision was made. According to some historians, they did so to have greater protection against possible French attacks; others claim that the reasons were technical, since the tortuous Spanish orography needed more power. Portugal also chose the width of Spanish railways, and other countries, such as Russia or Finland, did not accept the standard width either.

Various solutions

As for the different width of the roads, when going from Spain to France or making the opposite route, there have been problems at all limits. In the case of travelers, the problem has never been very serious, the change of train and ready! This has been done historically at the borders, until Pal invented the wagons that fit the two wide tracks. Since then, when passenger trains arrive at the border, passengers do not have to go down, since with the stationary train you can automatically change the width of the axles of the wagons. Then, when the wagons fit the width of the railway, a new machine is placed that pulls the train and can follow the journey.

Obviously, when goods are to be transported, the train change can be very complicated. However, XX. In the first half of the 20th century, since no other system existed, there was also a change of goods within the limits. On the border with La Junquera, for example, it was usual to change the train the orange boxes. This way of doing things disappeared in 1950. That same year, Transfesa opened the car axle replacement facility in Hendaia. That is, instead of changing the goods of wagons, the axes of the wagons begin to be changed. To do this, the company invented the wagons with the possibility of modifying the axle and made the appropriate facilities to carry out this work.

Today, the company Transfesa continues to make changes of freight train axis in Hendaia. The process is semi-automatic and changes an average of 400 axes daily. The truth is that it is a pretty brand. And as the changes are fast, the two axes of the wagon change quickly. But the trains have more than one wagon and also the change of axle is done with the train standing. Therefore, despite rapid shaft changes, time is lost.

Since 1992, the problems that until then were at the borders have appeared in more Spanish railways. In fact, in the year of the Expo of Seville the high-speed railway Madrid-Seville was inaugurated, which was endowed with most of the European railways: 1,435 millimeters. Looking ahead, the problem is expected to be greater, as according to the plan drawn up by the Spanish government all new high-speed railways will be carried out with the width of European railways.

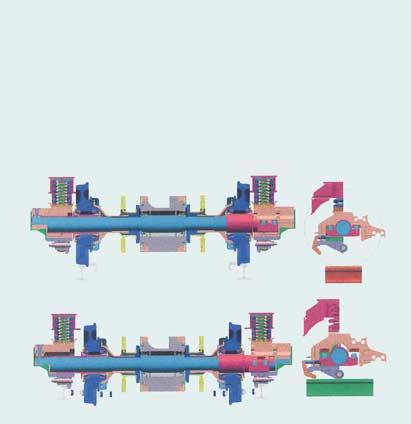

Operation of Brava

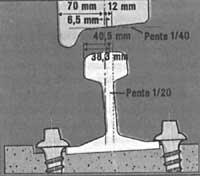

The boogie is based on a fixed axis (1). On it two sliding elements have been placed (2), that is, two elements that can be moved towards the center or ends of the axis. Bearings (3) and finally wheels (4) have been placed on bearings. In the central part of the axis a reducer (5) has been placed by a pulmonary axis (6) with coof. In the central axis it has been arranged by tapered bearings (7). The support shaft uses dental coupling (8) and flexible coupling (9) for wheel attachment. On the other hand, on the axis of photons there are two disc brakes (10). To ensure that the distance between the wheels is necessary, in the Boogio Brava has been placed a bolt (11) and roots (12). The roots approach slippery elements, while the bolt links the shaft body with mechanical elements. To avoid errors, the Brava boogie also has a safety bolt (13) to ensure that the distance between wheels is necessary at all times. This makes it impossible to release the rest of the bolts and the root during normal train travel.

When a change of width occurs, the axle load goes on some rollers (14). These rollers are placed on the side rails (15) of the track change zones, thus releasing the safety bolts. Once loose, with the help of the side rails (16) of the track, the wheels of the train can be moved inland or the ends of the axis.

Boogie Brava

Faced with this situation, operators seek solutions. CAF, a Beasain company, has its own: Boogie Brava, boogie that adapts the width of the axles of the wagons to the width of the railway without stopping the train.

Before the creation of the Boogie, the CAF research department established the characteristics that a possible new product should have. Most importantly, they needed a product that would automatically change the axle and adapt to the different railroad widths without stopping the train or altering the machine. The change would have to be fast at a minimum speed of 15 kilometers per hour, that is, in less than 5 seconds. The new product should also be able to circulate at high speed, as it should circulate along the roads that have been recently built and are to be built shortly, so the invention should have a minimum capacity of 220 kilometers per hour. Finally, it had to be suitable for most current trains and, of course, it had to meet all the security, reliability and comfort conditions currently required.

Once all these characteristics were considered, they began to work and at CAF they developed the Brava boogie. Boogie seems to be similar to conventional ones, but that's just an appearance.

After the development of the new product, numerous tests have been carried out with the Brava axis, both in the factory itself and in the railway. More than 600 railway modifications have been made at the Beasain plant, and in Seville, where the wide roads of Renfe and the different widths of the high-speed train converge, so many more have been done. The forecasts suggest that Brava could carry out the railway change at a speed of 15 kilometers per hour, but in the tests that have been carried out the reality has far exceeded the forecasts since they have managed to make the train change at a speed of 30 km/h.

In addition to the change tests, other tests have been carried out with Brava to know how the axis works at high speeds. In the wide roads of Renfe the tests reached 200 kilometers, while in the high-speed ones reached 275 kilometers. At first there was no intention of testing at speeds above 242 kilometers per hour, but the results until then were very satisfactory, so they decided to climb to 275. Therefore, the Brava axis has more easily exceeded the condition of being able to circulate at 220 kilometers per hour.

However, Brava's toughest trials have been conducted at the CAF test bench. The test bench is a test bench made for boogones that can expressly carry the Brava axis. The new boogie has been indefinitely working day and night. CAF facilities have simulated different speeds, forces, pressures and situations. According to the work carried out in it, any railway axis would have a distance of one million kilometers, that is, the longest possible life of any axis. The Brava axis, the new product of CAF, suffered well the punishment imposed.

As seen, CAF has developed a product capable of solving the problem of railways of different width. This does not guarantee immediate success. In fact, Tecnalia has developed a similar system with technology acquired in Germany. Therefore, CAF and Talgo compete again. Although at the time of writing these lines I was pending to decide who would win the most, it cannot be denied that CAF had good letters, and by the time they are published it will be known if the expectations were met. However, having good cards in the business game where so much interest is mixed can be a mistake.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia