Ten advances in the car

1993/06/01 Otaolaurretxi, Jon Iturria: Elhuyar aldizkaria

1. ABS braking system

The anti-lock braking system on aircraft wheels is being applied in the last fifty years, but in cars the ABS system is also not twenty years old. The BMW house was the one that in 1973 installed this braking system for the first time to its largest car, the 7 series. Five years later, the Mercedes house followed the same path in its S cars.

Bosch succeeded in adapting the miniaturized electronic system to the harsh conditions of the car. The car engine is surrounded by temperature changes, vibrations and harsh conditions.

However, currently the ABS system is also installed in any small vehicle or is offered the possibility to place it, in the amount of 150,000 sts. (7,500 pounds) for more.

When the driver of a car hits with distress while it is running, the brake pedal becomes too strong and too long. That is why the wheels are blocked by sliding the entire car. As the car approaches the obstacle, the driver himself squeezes the pedal more and collides inevitably. The ABS system allows the wheels to remain locked completely even though the pedal is crushed on foot.

Electronic sensors on the wheels cut the brake fluid pressure shortly before the wheel is completely paralyzed. This prevents the car from sliding and the driver can avoid the obstacle driven by the steering wheel. With the ABS system it can be said that the wheel rotates at a very low speed to almost stop.

It should be clarified that the ABS braking system is not very effective when in winter there is ice or snow on the track.

2. Reduced consumption

In recent years it can be said that the fuel consumption of cars has decreased by an annual percentage. The rising price of oil in the 1970s and the fuel tax have to do with it.

Today there are many cars that burn about six liters per hundred kilometers. In this decline in consumption has had much to do with the aerodynamic form given to the car. However, with the risk of this decrease in consumption being compensated with better car performance, improvements have also been made to the engine itself.

The carburettor has been replaced by the injection system in the engine. In this system, the air/fuel mixture that the engine needs at all times is offered to you in the most appropriate proportion unlike the carburetor. In addition in the engine there is an injector per cylinder. The carburetor is unique for the entire engine. In the injection system, on the other hand, there is the possibility of cutting the fuel supply when the engine is decelerating (car braking).

Lately, cylinders with many valves are being placed in the engines. This allows better filling of the cylinders with fuel mixtures and better utilization of the energy of the streams improves performance.

However, new cars have increasing safety equipment or increasingly heavier anti-corrosive bodies that “engulf” consumption savings in part.

3. Aerodynamics

It can be said that formerly cars were cubes. When they worked, the air offered great resistance to these cars. However, it began to give a more aerodynamic form and take into account the coefficients Cx and SC x. Also, the faster the car, the more important these coefficients are. It is the aerodynamic coefficient corresponding to the shape Cx and the ratio between the coefficient SC x, Cx and the surface S that the vehicle offers in front of the air.

Two-thirds of the forces that prevent the advance of the car are aerodynamic. In addition, the mechanical strength or resistance of the tires decreases as the speed increases. Therefore, in aerodynamics the shape of the body is fundamental. However, this does not mean that two cars with Cx (e.g. 0.27) and S (e.g. 2.10 m 2) necessarily have the same shape.

In aerodynamics it is important that surfaces are “notched”. If the surface is not continuous, any slit or leak adds two or three tenths to the aerodynamic coefficient. Therefore, for example, edges of glasses of the car become as equal as possible with a body. The roof is now made with the minimum possible highlight, eliminating the edge that was placed longitudinally on the sides. Mirrors placed outside the car also have a rounded back.

When lowering a point the aerodynamic coefficient, it can be said that an average consumption savings of one hundred kilometers is one liter, and it should not be forgotten that the main reason for making the aerodynamic design fashionable has been this.

4th lamina windshield

Due to the demands of aerodynamics and safety, more and more glasses are placed in cars. The front windshield is also very large. It is also curved so as not to limit the visual field of the driver.

The glass must be flexible, as it must withstand the dynamic and thermal deformations of the vehicle and rigid so that the set is resistant. So far the ideal solution has been the tempering of glass, which met both conditions, but which is not so suitable for the safety of travelers. Tempered glass is not collision-resistant and does not cause serious damage to the passenger's head. It breaks into very small parts and only produces skin wounds, but glass dust is generated and if this powder enters the skin or (especially) in the eyes, the wounds can be important, even the glare of the person.

In the 1960s the wind rolling began to be placed in large cars and then in small ones. Mandatory since 1978. Subsequently, the windshield consists of two glass sheets, including a clear plastic sheet. In case of collision, the glass is attached to the plastic sheet without breaking. There is therefore no risk of dust entering the eyes or skin.

However, only the previous winds is laminated in today's cars, as the side and rear glass remain tempered glass.

5. Comfort equipment

Inside the car the driver and the comfort equipment of the passengers are increasingly numerous. Because the driver's front frame is full of controls, buttons and drivers, it is also necessary to occupy the interiors of the side doors. Normally these automatic comfort circuits are governed by electric power and electronic control.

In addition to electrically regulating windows and mirrors, doors also close and open electrically from a lock. Even with remote controls can be opened and closed in some cars. The ceiling can also be opened electrically and radio facilities are increasingly sophisticated. They have moved from the music listening cassette to the compact laser and two programs can be heard simultaneously in the same car thanks to the ear speakers.

Ergonomic seating improvement. Manual drive wheels are replaced by electric motors and the back of the seat can be adjusted to its size.

This year air conditioning is also being installed in smaller cars. The electronic speed regulator, the seat belt that is automatically dressed and the bag that inflates in 25 thousandths of a second in case of impact are some of the advances that will be started shortly.

However, this comfort equipment requires increasing energy consumption and a larger engine.

6th Catalytic Boat

The catalytic boat began to be installed in Germany and is currently in the process of being installed in all new European cars. This kind of filter does not remove all contaminants to exhaust gases. In addition, to place the catalytic canister, remove the carburetor from the engine. The air/fuel mixture that enters the cylinders is not always kept in the right proportion and the unburned gases can damage the catalytic canister. It is therefore placed in the injection engines. Only thus can carbon dioxide and nitrogen oxides (II) and (IV) be completely eliminated.

The catalytic vessel is a ceramic structure framed on a metal surface. The collection of honeycomb cells is covered by thin layers of platinum, rhodium and palladium. These precious metals oxidize and clean the gases.

Catalytic boats operate between 600 and 800 degrees. When the car engine starts up, therefore, its efficiency is much lower. In addition, lead destroys the aforementioned metals and the use of unleaded gasoline is mandatory.

We know that the catalytic canister does not completely solve the problem of contamination of the car exhaust, but that it is an interesting contribution cannot be denied.

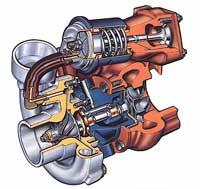

7. Turbocharger

The first ones were made before World War II, but because the machining systems were not sufficiently developed, the turbocharger did not extend to cars. The operating base is simple. The gas to be introduced into the cylinder is compressed previously, thus giving greater power to the engine. The burned gases are driven to a turbine, placing the rotor at a speed of 100,000 revolutions per minute. Using this force, another turbine compresses the air/fuel mixture to be introduced into the cylinder. For example, if the pressure is 0.7 bar, the mechanical parts are not subjected to force and the engine provides 30% more power.

The more the gas is compressed, the more it gets heated. In turn, the more it heats up, the more it expands. To solve the problem, an air/air heat exchanger is currently placed between the turbo and the cylinder, causing the cooking mixture to descend 100 degrees Celsius.

Turbochargers started to be placed in Formula 1 racing cars, but since then they can also be seen frequently in conventional cars, especially diesel cars. This is because the turbocharger is better suited to flexible low-turning motors.

8th. Corrosion protection

One of the most serious problems is the oxidation of the car body. The vehicle must remain on the front line throughout its life, often attacked by the sea crucible or hit by the thick salt deployed on the ground during frost. Therefore, today's cars are protected against corrosion.

Some automotive manufacturers offer their vehicles a ten-year anti-corrosion guarantee. Currently 60% of the total body of the car is protected by a layer of zinc of at least 10 microns before its painting. In addition, it can have a layer of zinc on one or both sides. The most dangerous areas (lower parts, door bars, etc. ), in addition, they usually have PVC layers. Robots allow, on the other hand, to insert wax into any groove, avoiding corrosion at these points.

Once the body is mounted, when it is submerged it is reprotected with phosphating. Before painting, the edges and holes are filled with cataphoresis treatment. Once all this is done, the paint layers are superimposed to finish the anti-corrosive process.

In addition, it should be noted that more and more pieces of polyester and fiberglass that are not affected by rust are used in the body.

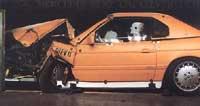

9. Protection against accidents

Today motorists "throw" a car almost a day against the concrete wall. The goal is to investigate the behavior of the car in the crash. The structure of the vehicle must be rigid enough on the one hand so that not all the deformation and collision energy goes to the internal passengers, but it is also not too rigid because in deformation it is not advisable to sharply cushion the energy of the shock. They seek an adequate level of elasticity and rigidity. In computer drills, passengers with belt in the crash against the concrete wall at 48 km/h should not suffer serious injuries. This is the requirement established by current legislation.

Car bodies are designed accordingly. They usually have deformation zones of different thickness so that when the shock occurs the energy is released at those points.

Inside all must wear seat belts and from now on will multiply the bags that automatically inflate in the shocks and protect passengers.

10. Electronic support

Electronics have allowed better control of the mechanisms and performance of the car. Electronically driven injection, in addition to reducing consumption, has helped to improve the use of fuel sent to the cylinder. Under the hood is installed all the electronic power plant in the car and not a single chip programmed for a job.

Also in suspension the reaction speed is regulated by varying the damping time depending on the road conditions. Electronic sensors reduce the pressure on the ABS system when necessary in braking. Capots, doors and windows are closed and opened electronically. In addition, the driver has in front a large number of electronic pilots that provide fundamental information for the operation of the vehicle: fuel tank status, oil level, water level and temperature, battery status, etc. In the garage they can see and detect engine failures on the computer screen.

The minicomputer is increasingly being placed in the car. Speed, consumption, kilometers, indoor temperature, etc. It can regulate and, if necessary, also offers voice information.

In addition, soon the voice of the owner will be known and will automatically open and start the doors. In addition, just by indicating where you want to go from your vacation, it will teach you what is the most comfortable, fast and free route at that time.

Gai honi buruzko eduki gehiago

Elhuyarrek garatutako teknologia